Polyphenylene Oxide (PPO) is a high-performance engineering thermoplastic renowned for its exceptional dimensional stability, heat resistance, and electrical insulating properties. In plastic injection molding, PPO is distinguished by its ability to meet the rigorous demands of advanced applications across various industries, including automotive, electronics, and medical devices. However, effectively molding PPO requires a deep understanding of its unique characteristics and specific processing requirements.

This blog post is designed to guide you through the essential considerations for PPO plastic injection molding. We will delve into the material properties of PPO, its advantages for industrial use, and the critical molding parameters that must be controlled to harness the full potential of this versatile polymer. Whether you are a seasoned manufacturer or new to using PPO, this article will equip you with the knowledge needed to optimize your injection molding processes and achieve high-quality results with PPO.

Understanding PPO Plastic

Polyphenylene Oxide (PPO) is a thermoplastic with distinct properties that make it highly valued in various high-demand applications. To effectively utilize PPO in injection molding, it is essential to grasp its unique chemical and physical characteristics and advantages in industrial applications. This section will delve into these areas to provide a solid foundation for those working with PPO.

Chemical and Physical Properties

High Melting Point: PPO has a higher melting point than many other thermoplastics, allowing it to perform well in high-temperature applications.

Low Moisture Absorption: PPO exhibits deficient moisture absorption, making it ideal for applications where dimensional stability is crucial under varying environmental conditions.

Excellent Dimensional Stability: PPO's inherent stiffness and stability ensure that parts maintain shape and size, even under mechanical stress or thermal exposure.

High Heat Resistance: PPO can withstand continuous exposure to heat, making it suitable for components in electronic and automotive industries that are near heat-generating elements.

Advantages of Using PPO

Superior Mechanical Properties: PPO is known for its high strength and impact resistance, essential for durable, long-lasting parts.

Electrical Insulating Properties: With its excellent insulating abilities, PPO is often used in electrical and electronic applications, such as connectors and parts for household appliances.

Resistance to a Wide Range of Chemicals: PPO's chemical resistance makes it resistant to acids, bases, and detergents, which benefits applications in chemical processing environments.

Aesthetics and Finish: Beyond functional benefits, PPO also provides a smooth surface finish, which is aesthetically pleasing and can eliminate the need for post-processing in visible components.

Pre-Molding Considerations

Before beginning the injection molding process with Polyphenylene Oxide (PPO), several critical factors must be addressed to ensure the quality and efficiency of the final products. Proper handling and preparation of the material, as well as configuring the equipment appropriately, are essential steps that can significantly influence the outcome of the molding process.

Material Handling and Preparation

Drying PPO: Despite its low moisture absorption, PPO must be thoroughly dried before processing to prevent quality defects, such as splay or brittleness, in the final product. The recommended drying conditions typically involve heating the material to a specific temperature (usually around 120°C) for 3 to 4 hours in a dehumidified dryer.

Material Storage: PPO should be stored in a cool, dry place away from direct sunlight and moisture to maintain quality. Proper storage ensures the material's properties remain consistent, reducing the variability risk during molding.

Handling Precautions: Handling PPO requires attention to avoid contamination with other materials or debris, which can affect the appearance and integrity of molded parts. Using dedicated equipment and containers for PPO is crucial to keep it free from impurities.

Equipment Requirements

Machine Calibration: Injection molding machines used for PPO should be calibrated and tested to operate at higher temperatures required by PPO. It ensures that the polymer melts correctly without degrading.

Tooling Material: Due to the high processing temperatures of PPO, the mold and other tooling components should be made of materials that can withstand these conditions without warping or wearing down quickly. Tool steels or aluminum with high thermal conductivity are commonly used.

Corrosion Resistance: PPO can be corrosive to certain metals when melted, so it's essential to use corrosion-resistant materials for parts of the injection molding machine that come into contact with the molten plastic. It helps extend the equipment's life and maintain the moldings' quality.

Optimizing Machine Settings

Injection Speed and Pressure: PPO requires precise control over injection speed and pressure to fill the mold effectively and achieve the desired part quality because of its inherent properties. These parameters must be adjusted according to the part design and mold characteristics.

Temperature Profiles: Setting up the correct temperature profiles for the barrel, nozzle, and mold is crucial. The melt temperature should be high enough to ensure smooth flow but not so high as to cause thermal degradation of the polymer.

Design Considerations for PPO Parts

Designing parts for injection molding using Polyphenylene Oxide (PPO) requires careful consideration of the material's properties and how they interact with the design features of the part. It's crucial to consider specific design guidelines tailored for PPO to ensure optimal functionality and manufacturability. This section explores essential design considerations to maximize the potential of PPO in injection molded parts.

Wall Thickness

Uniformity: Designing parts with uniform wall thickness is crucial to minimize issues such as warping, sink marks, and uneven cooling; familiar with varying wall thicknesses. PPO parts should maintain consistent wall thickness to ensure even flow and cooling.

Optimal Thickness: While PPO can fill thin sections due to its flow properties, maintaining an optimal wall thickness between 1.5mm and 3mm helps balance strength and material efficiency. This range can vary depending on the size and complexity of the part. Still, it's an excellent general guideline to start with.

Gate Location and Size

Strategic Placement: The gate, where the molten PPO enters the mold, should be strategically placed to ensure uniform filling of the mold cavity. Placing the gate at the thickest part of the mold or near the center of symmetry can help reduce pressure loss and ensure more uniform cooling and shrinkage.

Appropriate Sizing: The gate size is equally essential, as it affects the speed and pressure of the injection. A gate that's too small can lead to higher shear rates and potentially degrade the PPO, while a gate that's too large might cause aesthetic issues and require more post-processing work. Finding the right balance is critical to optimizing the molding process.

Rib Design

Support with Ribs: Ribs can enhance the stiffness of PPO parts without significantly increasing wall thickness. Designing ribs with a thickness of about 0.5 to 0.7 times the adjacent wall thickness helps provide structural support without causing sink marks.

Placement and Spacing: Ribs should be evenly spaced and connected to walls or other ribs to support material flow and minimize stress concentrations. Proper rib design can significantly enhance the mechanical strength of PPO parts.

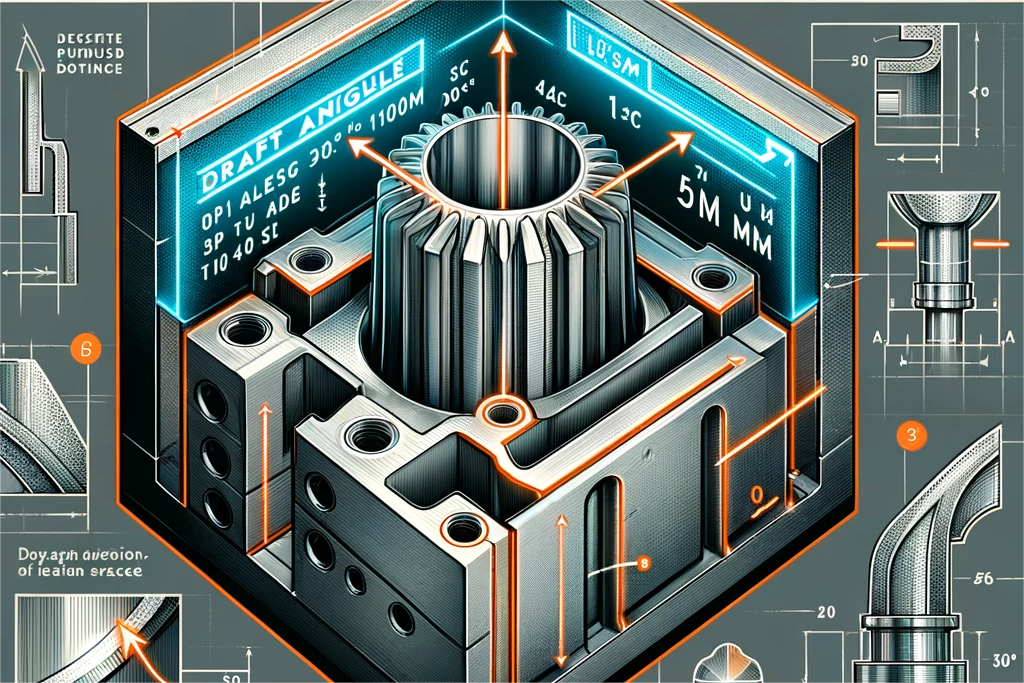

Draft Angles

Ease of Ejection: Incorporating draft angles into the part design is essential to facilitate the easy ejection of the part from the mold. For PPO, a minimum draft angle of 1 to 2 degrees for vertical surfaces is recommended, depending on the depth and complexity of the part.

Aesthetic Considerations: Draft angles should also consider the aesthetic requirements of the part. Strategic placement and minimal visibility of these angles help maintain the desired appearance without compromising functionality.

Surface Textures and Finishes

Texturing Considerations: PPO parts can be designed with various surface textures, improving grip or aesthetic appeal. However, the depth and intricacy of textures need to be carefully controlled to avoid issues during the molding process, such as incomplete filling or difficulty in mold release.

Finishing Processes: If a high-quality finish is required, post-processing techniques such as sanding, painting, or plating can be considered. These should be factored into the design phase to ensure compatibility with the intended finishing process.

By incorporating these design considerations, engineers and designers can take full advantage of PPO's unique properties in injection molding applications. Thoughtful design optimizes the manufacturing process and enhances the final product's quality and performance, ensuring it meets the required specifications and performs well in its intended applications.

Common Molding Challenges with PPO

While Polyphenylene Oxide (PPO) offers a range of beneficial properties for injection molding, working with this material also presents specific challenges that must be managed effectively. Understanding these issues and implementing strategic solutions can significantly enhance the molding process and the quality of the final products. This section addresses some of the most common molding challenges encountered with PPO and provides practical solutions.

Warpage and Shrinkage

Causes: Warpage and shrinkage in PPO parts can occur due to uneven cooling, incorrect processing parameters, or inappropriate part design. These issues can distort the part, affecting its dimensional accuracy and aesthetic quality.

Solutions: To minimize warpage and shrinkage, ensure uniform wall thickness in the design, and optimize mold temperature control. Adjusting the cooling rate and maintaining uniform temperature across the mold is crucial. Modifying the part geometry and increasing the number of cooling channels may help achieve more consistent cooling.

Surface Imperfections

Causes: Surface imperfections such as splay marks, blush, or burn marks can arise from improper material handling, excessive moisture, high injection speeds, or high melt temperatures.

Solutions:

Splay Marks: Reduce and control moisture content through thorough pre-drying of PPO and optimize back pressure and injection speed to avoid trapping air.

Blush: Adjust mold temperatures and ensure adequate cooling to prevent overheating of the outer surfaces during the injection phase.

Burn Marks: Decrease the melt and mold temperatures and adjust the injection speed to prevent the material from degrading due to excessive heat.

Sticking in the Mold

Causes: PPO components might stick in the mold if the ejection system is not designed correctly or the draft angles are insufficient.

Solutions: Review and adjust the draft angles to ensure they are adequate for easy ejection. Consider polishing the mold surfaces or applying a mold release agent to facilitate a smoother release. Optimizing the ejection mechanism with proper placement and number of ejector pins can help reduce sticking.

Molecular Degradation

Causes: Molecular degradation can occur when PPO is subjected to excessive heat for prolonged periods during the molding process.

Solutions: Carefully control the processing temperatures, especially the melt temperature. Using a lower melt temperature within the acceptable range for PPO can help preserve its molecular integrity. Also, ensure the cycle times are optimized to reduce the material’s exposure to heat.

Cracking Problem

Causes: PPO will crack when it encounters mineral oil, ketone, and ester solvents under stress or during injection molding. Regarding organic solvents, PPO is not corrosive to acids, alkalis, and detergents. However, mineral oil, ketone, and ester solvents will cause stress cracking under stress. In addition, PPO will also be melted and dissolved by organic solvents such as aliphatic hydrocarbons, halogenated aliphatic hydrocarbons, and aromatic hydrocarbons.

Solution:

1. During the preparation of PPO materials, strict attention should be paid to avoid contamination by mineral oil ketone and ester solvents.

2. Clean the mineral oil ket, one, and ester solvents in the mold during the injection molding. When the mold temperature needs to be heated, use a water temperature machine instead of an oil temperature machine.

3. After injection molding, PPO parts should avoid contact with mineral oil, ketone, and ester solvents.

Post-Molding Operations

After the injection molding process, Polyphenylene Oxide (PPO) parts often require various post-molding operations to meet specific functional and aesthetic standards. These operations are critical for ensuring the parts are ready for assembly or end-use. This section delves into the techniques and considerations for effectively handling PPO components' finishing, trimming, and assembly.

Trimming and Finishing

Techniques: Once ejected from the mold, PPO parts may have excess material, such as flash, sprues, or runners, that need to be trimmed off. Techniques such as manual trimming with hand tools, automated trimming with CNC machines, or laser cutting provide precise control and minimize damage to the parts.

Finishing Processes: PPO parts can undergo various finishing processes to enhance surface appearance or properties. These include sanding, polishing, painting, or plating. Sanding and polishing can remove any minor surface imperfections and prepare the surface for painting or plating, which can be used to improve aesthetic appeal or corrosion resistance.

Assembly Considerations

Adhesive Bonding: PPO can be effectively bonded with various adhesives, including epoxy resins and cyanoacrylates. Surface preparation, such as cleaning and light abrasion, is crucial for a strong bond.

Ultrasonic Welding: This method is suitable for joining PPO parts as it creates strong welds without introducing contaminants or significant thermal stress. Parameters like welding time, pressure, and amplitude should be finely tuned based on the specific requirements of the PPO material and the part design.

Mechanical Fastening: Screws, rivets, and other mechanical fasteners are commonly used for PPO parts, especially in applications requiring disassembly. Designing with appropriate tolerances and reinforcing areas subjected to mechanical stress is essential to avoid cracking or deformation.

Quality Control

Inspection: Post-molding inspection ensures that all finished parts meet the required specifications. It can involve visual inspections, dimensional checks using gauges or CMMs, and functional testing to verify that the parts perform as intended.

Testing: For applications in critical environments, additional testing such as stress testing, heat resistance testing, or electrical testing may be necessary to confirm the part's suitability for its intended use.

Packaging and Handling

Safe Packaging: Given the high performance of PPO in various applications, proper packaging is essential to protect the parts during storage and transportation. Use materials that prevent static and moisture exposure, and consider custom packaging solutions for unusually shaped or delicate parts.

Handling Guidelines: Establish clear handling guidelines to avoid damage to the parts. Training personnel on handling finished PPO parts can reduce the risk of scratches, dents, or other damage before the parts reach the end user.

PPO Injection Molding Case Studies

Exploring real-world applications and success stories of Polyphenylene Oxide (PPO) injection molding provides valuable insights into different industries' practical challenges and innovative solutions. This section presents case studies highlighting PPO's effectiveness in various applications, demonstrating how understanding and addressing specific molding considerations can lead to successful outcomes.

Case Study 1: Automotive Industry

Background: A leading automotive manufacturer required high-performance components that could withstand high temperatures and chemicals typically encountered in engine compartments.

Challenge: The components needed to maintain structural integrity and dimensional stability under extreme conditions without increasing the vehicle's weight.

Solution: The manufacturer chose PPO for its excellent heat resistance and mechanical properties. Adjustments were made to the injection molding process to accommodate the high melting point of PPO, ensuring smooth flow and complete cavity filling.

Outcome: The PPO components met the high-performance criteria and contributed to reducing the vehicle's weight, enhancing fuel efficiency, and lowering emissions. The success led to broader adoption of PPO in other parts of the vehicle.

Case Study 2: Consumer Electronics

Background: A consumer electronics company needed durable, aesthetically pleasing enclosures for a new line of high-end gadgets.

Challenge: The enclosures required a material that could provide excellent electrical insulation and resistance to wear and tear while achieving a high-quality finish.

Solution: PPO was selected for its superior strength, electrical insulation properties, and ease of finishing. Special attention was given to the mold design to prevent defects such as warping and ensure a high-quality surface suitable for visible consumer products.

Outcome: The resulting PPO enclosures were durable and functional, featuring a sleek, attractive finish that appealed to consumers. The project underscored PPO's value in high-end markets where performance and aesthetics are critical.

Case Study 3: Medical Devices

Background: A medical device manufacturer required components that could withstand repeated sterilization cycles without degrading.

Challenge: The components needed to be made from a material that was both biocompatible and capable of maintaining dimensional stability and structural integrity after exposure to high temperatures and harsh chemicals used in sterilization.

Solution: The company chose PPO for its excellent chemical resistance and stability under thermal stress. The injection molding parameters were finely tuned to optimize the properties of PPO, focusing on precise temperature control and adequate cooling times to enhance the material's performance.

Outcome: The PPO medical components successfully withstood repeated sterilization, maintaining their performance and safety characteristics. The success of this application demonstrated PPO's potential in critical healthcare environments, leading to its increased use in other medical applications.

What We Can Do in PPO Plastic Injection Molding

PPO plastic injection molding offers numerous innovation and performance enhancement opportunities across various industries. Here's a comprehensive overview of what can be achieved through the skillful use of PPO in injection molding processes:

High-Performance Component Manufacturing

Automotive: Utilize PPO to produce components that require excellent heat resistance and dimensional stability, such as under-hood automotive parts. PPO's lightweight properties contribute to fuel efficiency and emission reduction.

Electronics: Manufacture connectors, enclosures, and other components where electrical insulation and heat resistance are crucial. PPO's durability and aesthetic qualities make it ideal for visible parts in consumer electronics.

Medical Devices: Create biocompatible, sterilization-resistant parts necessary for medical applications. PPO's resistance to high temperatures and chemicals makes it suitable for repeated sterilization without compromising the integrity or safety of medical devices.

2. Enhanced Design Flexibility

Leverage PPO's flow properties to design complex geometries and intricate details that other materials might not accommodate. Its low shrinkage and excellent dimensional stability allow precise, detailed parts to be produced without warping.

Utilize PPO's ability to be colored during molding to produce aesthetically pleasing designs without additional painting or finishing.

3. Sustainable Solutions

Implement PPO in applications aiming for greater sustainability. Its durability and long lifespan reduce the need for frequent replacements, contributing to waste reduction.

Explore recycling of PPO parts. Although PPO recycling is challenging, advances in chemical recycling processes may allow for more sustainable lifecycle management of PPO products.

4. Overcoming Molding Challenges

Address common issues such as warping, shrinkage, and surface imperfections by optimizing molding parameters like temperature settings, cooling times, and material handling practices.

Develop specialized tooling and equipment that cater to PPO's specific requirements, such as higher temperature capabilities and corrosion resistance, to extend mold life and enhance part quality.

5. Customization and Innovation

Push the boundaries of customization in industries like automotive and consumer products by leveraging PPO's versatility. Its excellent mechanical properties and finish options allow customized, high-quality parts to be created.

Innovate new applications of PPO by combining it with other materials or through modifications at the molecular level to create composites or blends that meet specific industry needs.

6. Cost-Effective Manufacturing

Utilize the efficiency of PPO injection molding to produce parts at high volumes, reducing unit costs and improving production timelines. Advanced injection molding techniques can minimize material waste and energy usage.

7. Comprehensive Quality Assurance

Implement rigorous testing and quality control protocols to ensure that PPO parts meet stringent industry standards and regulatory requirements. It includes dimensional accuracy, resistance properties, and performance under various environmental conditions.

评论

发表评论