PC lampshade injection molding is vital in producing high-quality lampshades, offering durability, versatility, and aesthetic appeal. However, like any manufacturing process, it has its fair share of challenges. Addressing these challenges promptly is crucial to ensure the efficiency and quality of the final product.

This article will delve into the common problems encountered during PC lampshade injection molding and explore practical solutions and best practices to overcome them. By understanding the root causes of these issues and implementing proactive measures, manufacturers can optimize their processes and enhance overall productivity.

Common Problems in PC Lampshade Injection Molding

While a highly effective manufacturing process, PC lampshade injection molding often encounters several common challenges that can affect the quality and efficiency of production. Understanding these problems and their underlying causes is essential for implementing effective solutions. Below are the main issues faced during PC lampshade injection molding:

Warping and Deformation

Causes:

Uneven Cooling: Variations in cooling rates across the mold can lead to differential shrinkage, causing warping and deformation.

Inadequate Mold Temperature Control: Fluctuations in mold temperature during the cooling phase can result in uneven material solidification, leading to warping.

Improper Material Flow: Insufficient material flow into certain areas of the mold can create localized stresses, causing warping upon cooling.

Effects on the final product:

Dimensional Inconsistencies: Warping and deformation result in deviations from desired dimensions, impacting the fit and finish of lampshades.

Poor Aesthetics: Deformed lampshades detract from visual appeal, affecting product aesthetics and customer satisfaction.

Compromised Functionality: Warping may affect the structural integrity of lampshades, leading to performance issues such as uneven light diffusion.

Solutions:

Improved Cooling Systems: Enhancing cooling efficiency through advanced cooling channels or conformal cooling designs promotes uniform solidification and reduces warping.

Mold Temperature Control: Maintaining precise mold temperatures throughout the molding cycle minimizes thermal gradients, mitigating warping and deformation.

Optimize Material Flow: Ensuring proper gate design and runner systems promote uniform material distribution, reducing the risk of localized stresses and warping.

Surface Defects

Causes:

Improper Material Flow: Inadequate material flow or excessive injection pressure can result in flow marks or surface irregularities.

Mold Contamination: Residual contaminants or inadequate mold maintenance can lead to surface defects such as burn marks or specks.

Excessive Injection Pressure: High pressure can cause material shearing or flashing, resulting in surface defects.

Impact on aesthetics and functionality:

Reduced Visual Appeal: Surface defects detract from the smooth, uniform appearance of lampshades, affecting overall aesthetics.

Light Diffusion Impairment: Surface irregularities may interfere with light diffusion properties, impacting the quality of illumination.

Material Integrity Compromised: Severe defects like burn marks or specks can compromise material integrity, leading to premature failure.

Remedial actions:

Mold Maintenance: Regular cleaning and maintenance of molds prevent contamination and ensure smooth surface finishes.

Optimize Injection Parameters: Fine-tuning injection speed and pressure parameters prevents material shearing and reduces the risk of surface defects.

Mold Release Agents: Proper application of mold release agents facilitates easy demolding and reduces the risk of surface sticking or marking.

Dimensional Inaccuracies

Root causes:

Variations in Mold Temperature: Inconsistent mold temperatures can lead to differential shrinkage, resulting in dimensional inaccuracies.

Pressure Inconsistencies: Variations in injection or packing pressure can affect material flow and packing density, impacting dimensions.

Material Flow Control: Inadequate control over material flow rates or injection speeds can result in non-uniform filling, leading to dimensional variations.

Implications for assembly and performance:

Assembly Challenges: Dimensional inaccuracies may hinder the assembly process, requiring additional adjustments or modifications.

Performance Limitations: Deviations from specified dimensions may affect the fit and functionality of lampshades, compromising performance.

Quality Assurance Concerns: Dimensional inaccuracies negatively affect product quality, customer satisfaction, and brand reputation.

Corrective measures:

Temperature Control: Precise control over mold temperatures ensures uniform material shrinkage and consistent part dimensions.

Injection Parameter Optimization: Fine-tuning injection parameters such as pressure and speed promotes uniform material flow and packing, reducing dimensional variations.

Mold Design Modifications: Incorporating uniform wall thicknesses and adequate draft angles minimizes shrinkage-induced distortions, enhancing dimensional accuracy.

Anti-UV Ingredients

a. The effect of adding anti-UV ingredients:

UV Protection: Anti-UV ingredients protect against UV degradation, prolonging the lifespan of lampshades.

Material Compatibility: Some anti-UV additives may affect material properties or processing characteristics, impacting moldability.

b. Problems easily caused by adding anti-UV ingredients:

Material Degradation: Incompatibility between anti-UV additives and PC resin may lead to material degradation or discoloration.

Flow Inconsistencies: Changes in material viscosity or flow behavior due to anti-UV additives can result in filling or packing issues.

c. Corrective measures:

Material Testing: Conduct compatibility tests to ensure the selected anti-UV additives are compatible with PC resin.

Processing Parameter Adjustment: Fine-tuning processing parameters such as melt temperature and injection speed to accommodate changes in material properties.

Light Diffusing Agents

a. The role of adding light diffusing agent:

Enhancing Aesthetics: Light diffusing agents disperse light evenly, creating a soft, diffuse illumination effect for lampshades.

Optical Properties: Proper dispersion of light diffusing agents improves light transmission properties, enhancing overall illumination quality.

b. Problems easily caused by adding light diffusing agent:

Inadequate Dispersion: Improper dispersion of light-diffusing agents may result in uneven light distribution or visible streaks.

Surface Irregularities: Uneven distribution of light diffusing agents can lead to surface defects such as mottling or streaking.

c. Corrective measures:

Mixing Optimization: Ensuring thorough and uniform dispersion of light-diffusing agents within the polymer matrix through optimized mixing processes.

Processing Conditions Adjustment: Fine-tuning processing conditions such as melt temperature and injection speed to promote uniform distribution of light diffusing agents.

Color Masterbatch

a. The role of adding color masterbatch:

Color Enhancement: Color masterbatches impart vibrant hues and shades to lampshades, enhancing visual appeal and customization options.

Consistent Coloration: Properly formulated color masterbatches ensure uniform coloration throughout the molded part.

b. Problems easily caused by adding color masterbatch:

Color Inconsistency: Improper dispersion or formulation of color masterbatch may result in color variations or streaks within the molded part.

Material Degradation: Incompatibility between color masterbatch and PC resin may lead to material degradation or reduced mechanical properties.

c. Corrective measures:

Color Matching Tests: Conducting color matching tests to ensure the desired color is achieved consistently across production batches.

Formulation Adjustment: Fine-tuning the formulation of color masterbatch to improve compatibility with PC resin and prevent material degradation.

Solutions and Best Practices

Addressing the common problems encountered during PC lampshade injection molding requires a combination of strategic solutions and best practices. Manufacturers can enhance product quality and production efficiency by optimizing mold design, selecting suitable materials, and fine-tuning process parameters. Below are vital solutions and best practices to mitigate challenges in PC lampshade injection molding:

A. Mold Design Optimization

Importance of gate placement and venting: Proper gate placement and venting facilitate uniform material flow, reducing the risk of defects such as flow marks and surface irregularities.

Enhancing cooling efficiency: Efficient cooling systems help maintain consistent mold temperatures, minimizing warping and deformation issues.

Incorporating draft angles for easy ejection: Draft angles facilitate the smooth ejection of molded parts, reducing the likelihood of dimensional inaccuracies and surface damage.

B. Material Selection Considerations

Compatibility with PC resin: Choosing materials compatible with PC resin ensures optimal processing conditions and reduces the risk of material degradation.

Addressing material shrinkage: Understanding and compensating for material shrinkage during the design phase can help achieve accurate dimensional specifications.

Advantages of specialized grades: Utilizing specialized PC grades tailored for lampshade applications can enhance optical properties, durability, and aesthetics.

C. Process Parameter Adjustment

Temperature control for uniformity: Precise temperature control throughout the molding process ensures consistent material flow and minimizes the risk of surface defects and dimensional inaccuracies.

Injection speed and pressure optimization: Fine-tuning injection speed and pressure parameters based on material properties and mold design helps achieve optimal fill and pack conditions.

Cycle time management for productivity: Optimizing cycle times while maintaining quality standards maximizes production efficiency and reduces manufacturing costs.

Case Studies and Real-World Examples

This section will explore real-world case studies and examples illustrating how manufacturers have addressed common problems encountered during PC lampshade injection molding. These case studies highlight the challenges faced, the strategies implemented, and the outcomes achieved, providing valuable insights for industry professionals.

Resolving Warping Issues at Neway Lighting Solutions

Description of the problem:

Neway Lighting Solutions, a leading manufacturer of PC lampshades, faced persistent warping issues during the injection molding process. Warping affected product aesthetics and led to dimensional inaccuracies, impacting assembly and performance.

Steps were taken to diagnose and address the issue:

Comprehensive Analysis: Neway's engineering team conducted a thorough analysis of the injection molding process, focusing on cooling efficiency, mold temperature control, and material flow dynamics.

Enhanced Cooling Systems: By incorporating advanced cooling channels and optimizing cooling rates, Neway improved temperature uniformity across the mold, minimizing thermal gradients.

Mold Temperature Optimization: Precise control over mold temperatures was achieved by implementing temperature monitoring systems and automated control algorithms.

Material Flow Simulation: Utilizing advanced simulation software, Neway analyzed material flow patterns and identified areas prone to uneven filling. It enabled design modifications to promote uniform material distribution.

Results achieved:

Reduced Warping: By implementing these measures, Neway successfully mitigated warping issues, achieving more excellent dimensional stability and improved product aesthetics.

Enhanced Product Quality: Lampshades produced after implementing these solutions exhibited consistent dimensions, smoother surfaces, and superior optical properties.

Increased Production Efficiency: Neway's production efficiency improved with fewer rejects and less post-processing required, leading to cost savings and enhanced customer satisfaction.

Dimensional Accuracy Enhancement at LampTech Industries

Challenges faced:

LampTech Industries encountered challenges related to dimensional inaccuracies in PC lampshade production, leading to difficulties in assembly and performance.

Process optimization strategies deployed:

Mold Design Modifications: LampTech Industries redesigned molds to incorporate uniform wall thicknesses, adequate draft angles, and optimized gating and venting systems to minimize shrinkage-induced distortions.

Temperature Control: Precise control over mold temperatures was achieved by installing advanced temperature control systems and regular calibration procedures.

Injection Parameter Fine-tuning: LampTech optimized injection parameters such as injection speed, pressure, and packing time to promote uniform material flow and minimize dimensional variations.

Achievements and future considerations:

Enhanced Dimensional Accuracy: By implementing these strategies, LampTech achieved greater dimensional consistency, facilitating smoother assembly processes and improving product performance.

Continuous Improvement Culture: LampTech recognized the importance of fostering a culture of continuous improvement, encouraging ongoing experimentation and refinement of processes to achieve optimal results.

Future Considerations: LampTech aims to explore advanced technologies such as in-process monitoring and control systems to further enhance dimensional accuracy and overall production efficiency.

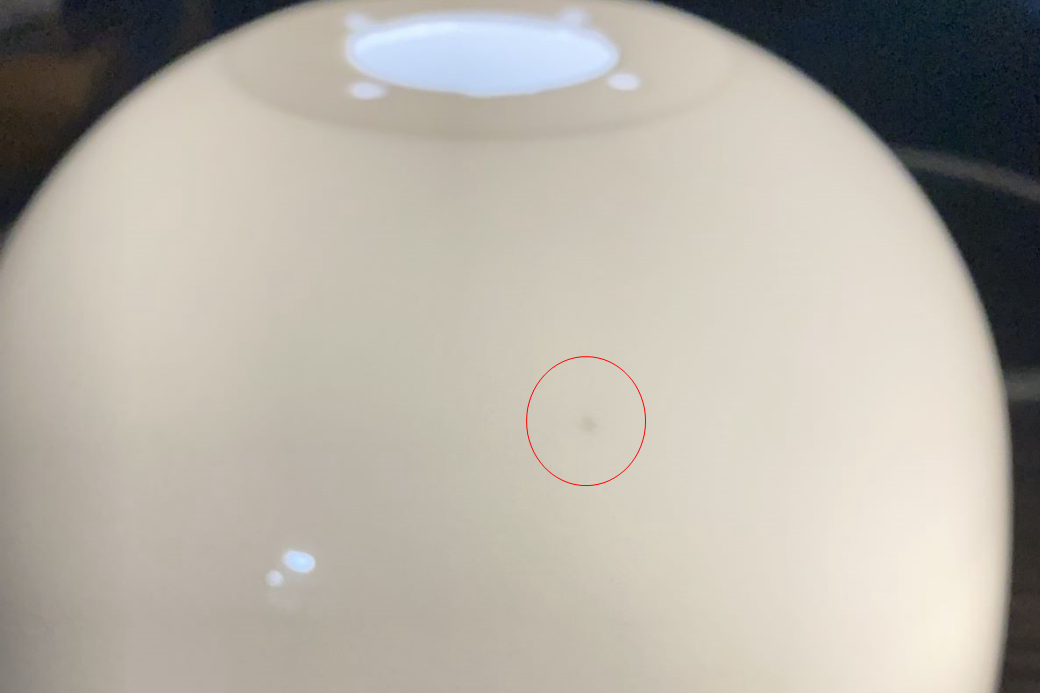

Lampshade Yellowing And Flow Marks Issues

Neway encountered the following problems when manufacturing a white translucent lampshade:

1. Yellowing during the injection molding process

2. Flow lines occur during the injection molding process

3. After one year of use, The injection-molded lampshade will have a color difference from the newly-injected lampshade.

Neway's R&D solved the above three problems through the elimination method. First, let's analyze the above three issues step by step.

1. Yellowing during the injection molding process: Since the raw material we use is PC, although we increase the mold temperature, the PC will not burn to yellow. At the same time, since other raw materials, such as toner, light-diffusing agents, and anti-UV ingredients, are added to the lampshade, we conclude that these added ingredients are not resistant to high temperatures. Once the injection mold temperature is too high, these components will carbonize, causing yellowing and blackening.

Solution: Replace these raw materials with high-temperature-resistant components.

2. Flow lines during the injection molding process: Due to the uneven mixing of the toner and PC particles added to the raw materials, uneven colors will occur during the injection molding process.

Solution: Replace the PC+toner material with granulated material to make the material color entirely consistent.

3. After one year of use, The injection-molded lampshade will have a color difference from the newly-injected lampshade.

The reason is that little or no anti-UV ingredients are added. Under sunlight, PC or other ingredients will age and degrade, making the lampshade look slightly yellow.

Solution: Increase the appropriate anti-UV ratio according to the actual thickness and transmittance

Conclusion

In conclusion, the PC lampshade injection molding process presents manufacturers with various challenges impacting product quality, aesthetics, and overall efficiency. However, manufacturers can overcome these challenges by understanding the common problems encountered during injection molding and implementing proactive solutions and best practices.

Throughout this article, we have discussed the root causes and effects of common issues such as warping, surface defects, dimensional inaccuracies, and problems associated with additives like anti-UV ingredients, light-diffusing agents, and color masterbatch. We have also explored practical solutions, including mold design optimization, material selection considerations, and process parameter adjustment.

Manufacturers can enhance product quality, minimize defects, and improve production efficiency by optimizing mold design, selecting suitable materials, and fine-tuning process parameters. Additionally, real-world case studies and examples have demonstrated the successful application of these strategies in resolving specific challenges encountered during PC lampshade injection molding.

In today's competitive manufacturing landscape, manufacturers must prioritize proactive troubleshooting and continuous improvement. By adopting a proactive approach to problem-solving and embracing innovation, manufacturers can stay ahead of the curve and deliver high-quality PC lampshades that meet customer expectations.

As we move forward, let us remain committed to excellence, embracing challenges as opportunities for growth and innovation. By leveraging the knowledge and insights shared in this article, manufacturers can optimize their PC lampshade injection molding processes and achieve sustainable success in the dynamic marketplace.

Remember, continuous improvement is not just a goal—it's a journey. Let us embark on this journey together, striving for excellence and innovation every step of the way.

What We Can Do In Plastic Injection Molding

Neway offers a variety of injection molding process options, including:

1. Plastic Injection Molding Service

4. Multi Shoot Injection Molding Service

And various standard and custom materials for injection molding, including:

Materials Optional In Injection Molding

Thermoplastics | Thermosets | |||

Medical-Grade silicone rubber | ||||

Optical silicone rubber | ||||

评论

发表评论