Brief Overview Of Transfer Die Stamping

Transfer die stamping is a crucial precision stamping process employed in producing custom metal parts, like Multi-Slide Metal Stamping, Deep Drawn Metal Stamping, and Progressive Die Stamping an area Neway excels in. In this method, a die set progressively shapes and forms a metal workpiece. Unlike single-stage processes, transfer die stamping involves the transfer of the workpiece between multiple dies, each contributing to the final shape.

One notable advantage of transfer die stamping is its efficiency in high-volume production, aligning with Neway's commitment to on-demand manufacturing. The process ensures tight tolerances and consistent part quality, factors vital in industries where precision is paramount.

In Neway's portfolio, transfer die stamping finds its application in diverse sectors, showcasing the versatility of this method. It includes the automotive industry for creating intricate components such as brackets, connectors, and structural elements. Moreover, Neway's expertise in transfer die stamping extends to other sectors like electronics, where precision and repeatability are essential.

By incorporating transfer die stamping into its array of manufacturing capabilities, Neway demonstrates a commitment to providing comprehensive solutions meeting the demands of clients across various industries. The efficiency and precision of transfer die stamping align with Neway's one-stop service approach, emphasizing its prowess as a leading custom parts manufacturer.

Basics of Transfer Die Stamping

Definition and purpose

Transfer die stamping is a precision metalworking process that involves progressively moving a metal strip or sheet through a series of stations (or dies) to shape, cut, and form the material into a finished part. The process utilizes multiple dies, each performing a specific operation, such as cutting, bending, or shaping before the final part is completed.

Transfer die stamping is to produce high-quality, complex metal parts in large volumes efficiently. By transferring the material from one die station to another, manufacturers can achieve intricate shapes and geometries with tight tolerances, ensuring uniformity and consistency across multiple parts.

This method is particularly advantageous for mass production of components in automotive, electronics, appliances, and aerospace industries, where precise, identical parts are required in significant quantities.

Transfer die stamping offers excellent repeatability, cost-effectiveness in high-volume production, and the ability to create parts with intricate designs while maintaining dimensional accuracy and quality.

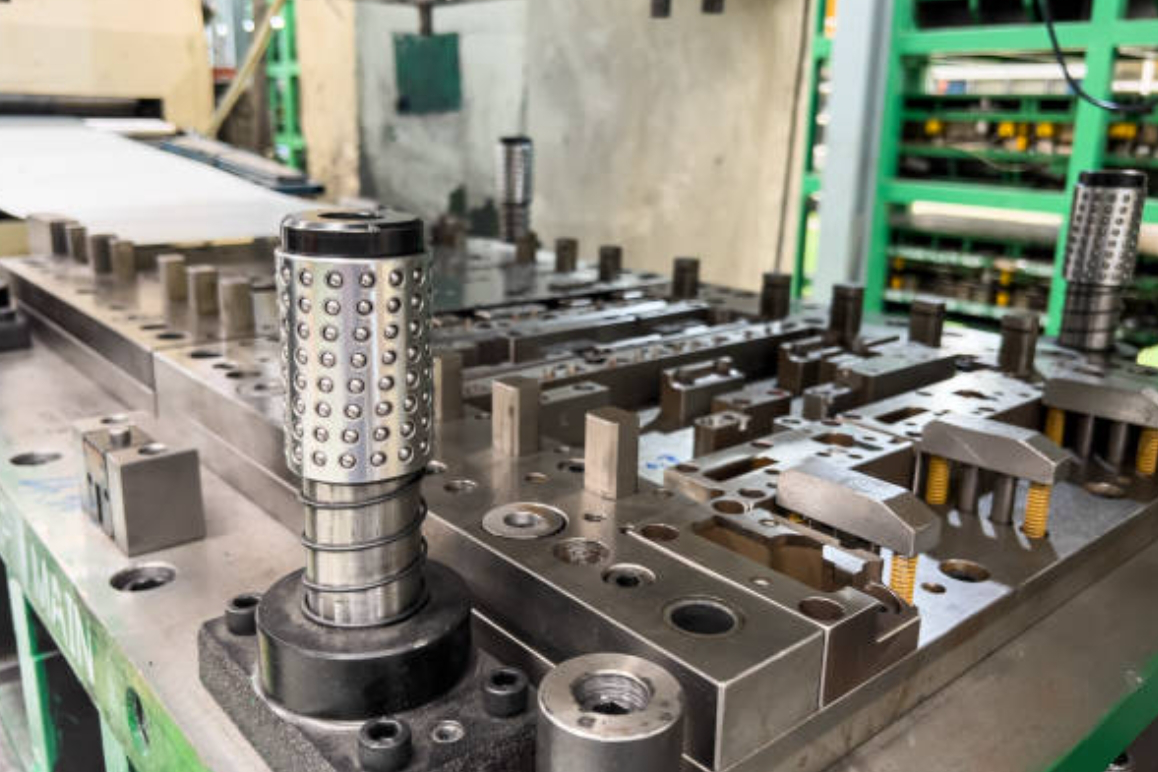

Key components involved

Transfer die stamping is a precision metalworking process used in mass production to create intricate metal parts. It involves transferring a metal strip or coil between multiple stations within a die, where each station performs a specific operation on the metal. The purpose is to shape, cut, or form the metal into the desired part.

This process typically comprises several key components:

Die: A tool composed of two halves, with cavities and forms that shape the metal. It includes multiple stations, each carrying out specific operations like cutting, punching, bending, or forming.

Transfer System: A mechanism that moves the metal strip or coil between stations within the die. This system ensures precise positioning and movement of the metal for each operation.

Feeder: This component feeds the metal strip or coil into the die and accurately positions it for the next operation. It ensures consistent and reliable feeding of the metal through the different stations.

Punches and Dies: These are the primary tools within each die station. The punches perform the cutting, punching, or forming actions, while the dies provide the necessary forms and shapes.

Press Machine: The transfer die stamping process uses high-speed stamping presses. These presses provide the force needed to perform the operations and are equipped to handle the rapid movements of the transfer system.

By utilizing these components in a synchronized manner, transfer die stamping achieves high precision and efficiency in producing intricate metal parts used across various industries.

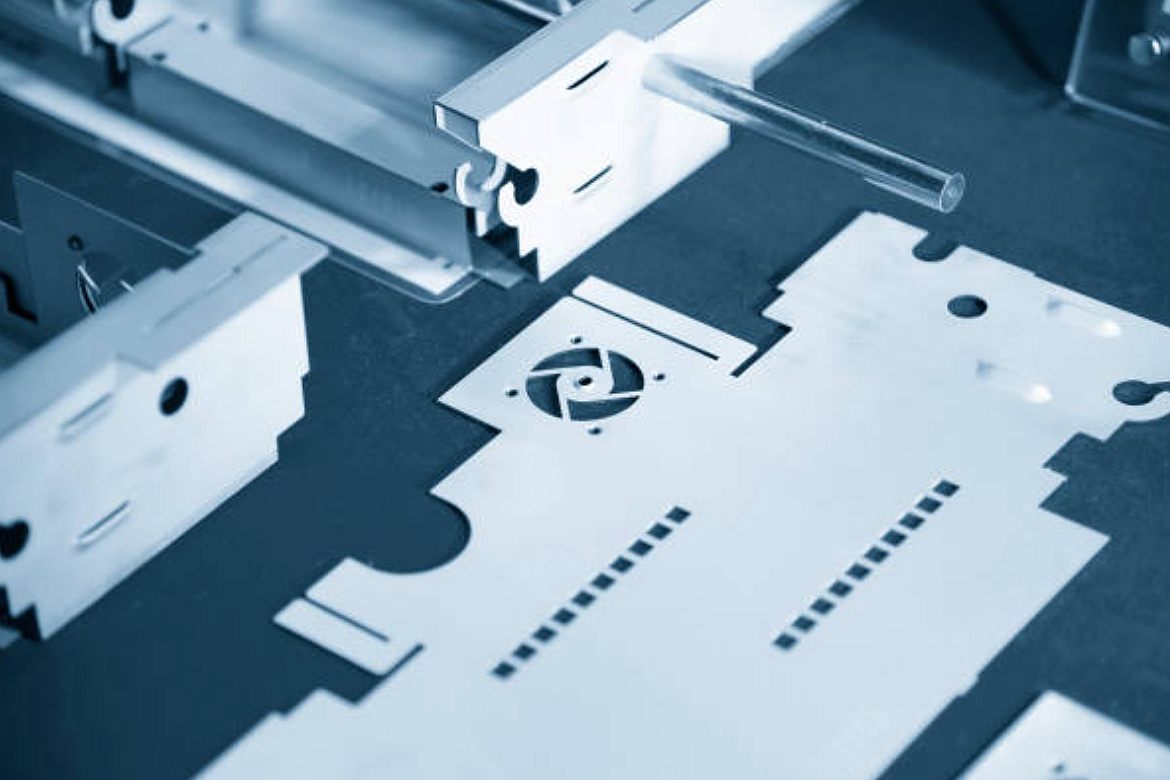

Transfer Die Stamping Process Steps

Material Preparation:

Raw materials, often metal sheets, are prepared based on the specifications of the final product. It involves cutting the sheets to the required size and ensuring they meet quality standards.

Die Design and Manufacturing:

The design of the stamping die is a critical step. It involves creating a precise blueprint that defines the shape and specifications of the final part. Once designed, the die is manufactured with precision to ensure accuracy in the stamping process.

Setup and Feeding:

The prepared material is then loaded into the stamping press. The setup includes configuring the press and die for the specific job. Material feeding systems ensure a consistent and accurate placement of the sheet metal.

Stamping Operation:

The press exerts force on the material, pushing it into the die cavities. This deformation process takes the shape of the die, creating the desired features on the metal. In transfer stamping, multiple operations may occur in different stations within the same press.

Part Ejection:

Once the stamping is complete, the newly formed part is ejected from the die. It can be an automated or manual process, depending on the setup.

Quality Inspection:

The stamped parts undergo rigorous quality checks to meet the specified tolerances and standards. This step is crucial to identify and address any defects or deviations.

Trimming and Additional Operations:

Sometimes, the stamped parts may undergo further operations like trimming excess material or adding features through secondary processes to achieve the final product specifications.

Packaging and Shipping:

The finished parts are then packaged for shipment. Proper packaging is essential to prevent damage during transportation.

With its efficiency and precision, transfer die stamping aligns with Neway's commitment to providing high-quality custom parts through sheet metal fabrication. If you have specific examples from Neway's experiences in transfer die stamping, incorporating those would further illustrate the company's expertise in this process.

Advantages of Transfer Die Stamping

Transfer die stamping is a highly efficient and precise sheet metal fabrication method with several advantages, making it a preferred choice for many applications. Here are some key benefits:

High Production Speed: Transfer die stamping excels in high-volume production, with a remarkable capability to produce many parts quickly. The process involves multiple stations that operate simultaneously, ensuring a rapid and continuous manufacturing flow.

Precision and Consistency: With Neway's expertise in sheet metal fabrication, transfer die stamping achieves tight tolerances and ensures consistent part dimensions. The dies are meticulously designed and maintained, producing uniform and high-quality components throughout the production run.

Cost-Effectiveness: The efficiency of transfer die stamping contributes to cost savings in large-scale production. The speed and automation involved in the process reduce labor costs per part, making it an economically viable option for projects with substantial volume requirements.

Material Utilization: Neway's commitment to sustainability is reflected in the material efficiency of transfer die stamping. The process minimizes material waste by optimizing the layout of parts on the sheet metal, ensuring that the raw material is utilized to its fullest potential.

Complex Part Production: Transfer die stamping is well-suited for creating intricate, complex parts with multiple features. Neway's advanced tooling capabilities and precision engineering enable the production of intricate components with minimal secondary operations.

Quick Die Changeovers: Neway's efficient production practices include streamlined die changeover processes. It reduces downtime between production runs, enhancing overall equipment effectiveness and maximizing productivity.

Material Versatility: Whether working with ferrous or non-ferrous metals, Neway's transfer die stamping can accommodate a wide range of materials. This versatility allows the production of diverse parts tailored to meet specific application requirements.

In conclusion, Neway's expertise in transfer die stamping positions it as a reliable and efficient method for high-volume sheet metal fabrication. The process's speed, precision, cost-effectiveness, and versatility make it a strategic choice for industries requiring large quantities of precision components.

Applications in Custom Parts Manufacturing

Transfer die stamping is crucial in custom parts manufacturing, providing a cost-effective and efficient solution. Neway employs transfer die stamping as a one-stop service provider for its precision sheet metal fabrication methods, ensuring high-quality custom parts for various industries.

In transfer die stamping, the process involves progressively transferring a metal sheet between multiple dies to progressively shape and form the desired part. This method is particularly advantageous for large-scale production, offering remarkable efficiency and precision.

One of the notable benefits of transfer die stamping is its ability to maintain tight tolerances. Neway's advanced machinery ensures that custom parts meet precise specifications with tolerances as low as ±0.005 inches. This level of precision is crucial, especially in industries where the functionality and reliability of components are paramount.

Moreover, transfer die stamping enhances production efficiency. Neway's streamlined processes and automated equipment enable rapid production cycles. This efficiency translates to higher productivity and reduced lead times, allowing clients to meet demanding project timelines.

By leveraging transfer die stamping, Neway achieves consistent and repeatable results. This reliability is further underscored by the company's commitment to quality control. Through stringent inspection protocols, Neway ensures that custom parts produced via transfer die stamping meet or exceed industry standards.

Transfer die stamping is an excellent method for manufacturing custom parts in various industries. Its efficiency and precision make it a valuable process in Neway's repertoire, particularly for high-volume production runs. Here are some critical applications and advantages:

Applications:

Automotive Industry: Transfer die stamping is extensively used for creating automotive parts like brackets, chassis, and structural elements due to its high-speed production capabilities and tight tolerances.

Electronic Components: Manufacturing parts for electronics often requires intricate designs and precise specifications. Transfer die stamping excels in producing connectors, terminals, and casings with consistent quality.

Consumer Goods: Custom metal parts for appliances, hardware, and everyday items benefit from transfer die stamping due to its ability to maintain dimensional accuracy and meet specific surface finish requirements.

Aerospace: In aerospace applications, where safety and precision are critical, transfer die stamping produces components like brackets, panels, and structural parts with high strength and tight tolerances.

Considerations When Choosing Transfer Die Stamping

When selecting transfer die stamping for custom parts manufacturing, several critical considerations come into play:

Complexity of Parts: Transfer die stamping suits intricate designs and tight tolerances. The method is effective for parts requiring multiple operations and intricate detailing.

Material Choice: Different materials might require specific stamping considerations. For instance, certain alloys or materials might demand specific die materials or temperature control during stamping to ensure accuracy and prevent material distortion.

Tolerance Requirements: Transfer die stamping offers high precision, often achieving tolerances within ±0.002 inches or better. Understanding your project's tolerance requirements is crucial in selecting the proper stamping method.

Production Volume: This method is well-suited for medium to high production volumes due to its efficiency and rapid production capabilities. For large runs, the initial tooling cost can be justified by the per-part cost reduction in high-volume production.

Tooling Cost and Lead Time: Tooling for transfer die stamping can be more complex and costly than other stamping methods, and the lead time for tooling creation should align with project deadlines.

Material Waste and Efficiency: Transfer die stamping minimizes material waste due to its precision, which benefits cost-efficiency and sustainability goals.

Secondary Operations: Consider whether secondary operations (bending, threading, or assembly) are necessary after stamping. Transfer die stamping can often integrate these operations into the stamping process, enhancing overall efficiency.

Surface Finish and Quality: Assess the surface finish requirements for the parts. Transfer die stamping generally yields excellent surface finishes, but specific finishes or textures require additional processes.

By evaluating these factors, Neway can leverage the advantages of transfer die stamping in producing high-quality, precise custom parts efficiently and cost-effectively.

Challenges And Solutions Of Transfer Die Stamping

Transfer die stamping is a critical process in sheet metal fabrication, and addressing its challenges effectively is paramount for achieving high-quality custom parts. Considering Neway's diverse manufacturing methods, let's delve into the challenges and innovative solutions.

Challenge 1: Precision and Tolerance Control

In transfer die stamping, ensuring tight tolerances is crucial for part conformity. Neway excels in this aspect, boasting an impressive tolerance control of ±0.005 inches. This precision is achieved through advanced stamping dies and meticulous process optimization.

Solution: Employing cutting-edge technology in metal stamping dies, Neway enhances precision by implementing computer-aided design (CAD) and computer-aided manufacturing (CAM). It ensures consistent accuracy and facilitates quick adjustments, minimizing downtime.

Challenge 2: Material Utilization Efficiency

Efficient material usage is a critical concern in stamping processes, affecting both cost-effectiveness and environmental sustainability. Neway strongly emphasizes optimizing material utilization, achieving a remarkable efficiency rate of 95%.

Solution: Neway maximizes material usage by implementing advanced nesting algorithms in sheet metal layout design. Additionally, integrating servo-driven presses enhances control over the stamping process, minimizing scrap and enhancing overall efficiency.

Challenge 3: Tooling Longevity and Maintenance

The wear and tear of stamping can impact production consistency and lead to increased downtime for maintenance. Neway prioritizes tooling longevity, ensuring minimal disruptions to the production workflow.

Solution: Utilizing high-quality tool steels and advanced surface treatments, Neway significantly extends the lifespan of stamping dies. Routine preventive maintenance is conducted based on a predictive maintenance model, reducing unexpected downtimes and enhancing overall productivity.

Challenge 4: Production Scalability

As demand fluctuates, achieving seamless production scalability is vital for promptly meeting customer requirements. Neway addresses this challenge by adopting a flexible manufacturing approach.

Solution: Neway employs a modular die design and quick-change tooling systems, allowing for swift transitions between different part configurations. This modular approach enhances production flexibility, enabling Neway to respond efficiently to varying order volumes.

In conclusion, Neway's commitment to precision, material efficiency, tooling longevity, and production scalability positions it as a leader in addressing the challenges of transfer die stamping. By leveraging cutting-edge technologies and innovative solutions, Neway ensures the consistent delivery of high-quality custom parts to meet the diverse needs of its clients.

评论

发表评论