Overview of CNC Machining

CNC machining is a versatile and precise manufacturing process that plays a pivotal role in low-volume custom parts production at Neway. It encompasses various techniques tailored to meet specific requirements. As a leading CNC machining manufacturer, Neway provides various CNC machining services for rapid Prototyping and low-volume production. Include:

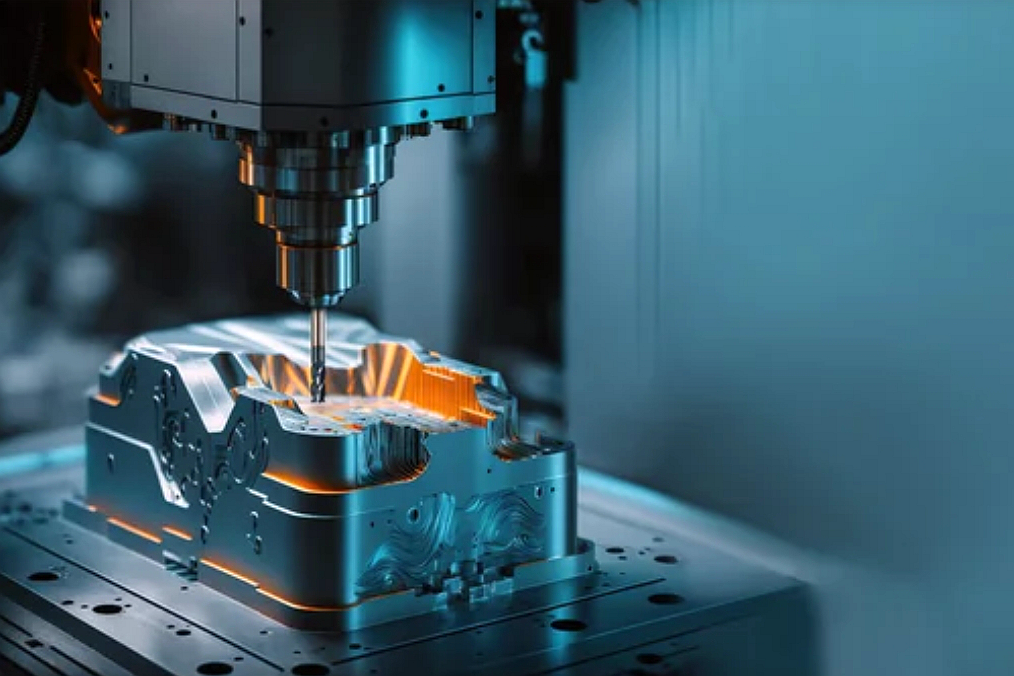

CNC Milling:

This process involves using computer-controlled machines to remove material from a workpiece. Neway employs state-of-the-art CNC milling technology, ensuring accuracy with tolerances as tight as ±0.005 inches.

Multi-axis CNC Milling:

Neway's multi-axis CNC milling capabilities enable intricate and complex part geometries. Advanced multi-axis machines enhance efficiency, reducing production time by up to 25%.

CNC Turning:

In CNC turning, Neway excels in precision machining through the rotation of a workpiece. Our CNC turning processes guarantee exceptional surface finishes, achieving roughness values as low as 0.2 micrometers.

Multi-axis CNC Turning:

Multi-axis CNC turning at Neway offers enhanced flexibility, enabling the production of highly detailed components. Our multi-axis turning centers deliver a 30% increase in productivity compared to conventional machines.

EDM (Electrical Discharge Machining):

Neway employs EDM for intricate shapes and delicate features. With EDM, we achieve accuracies within ±0.002 inches, ensuring the production of intricate and high-precision components.

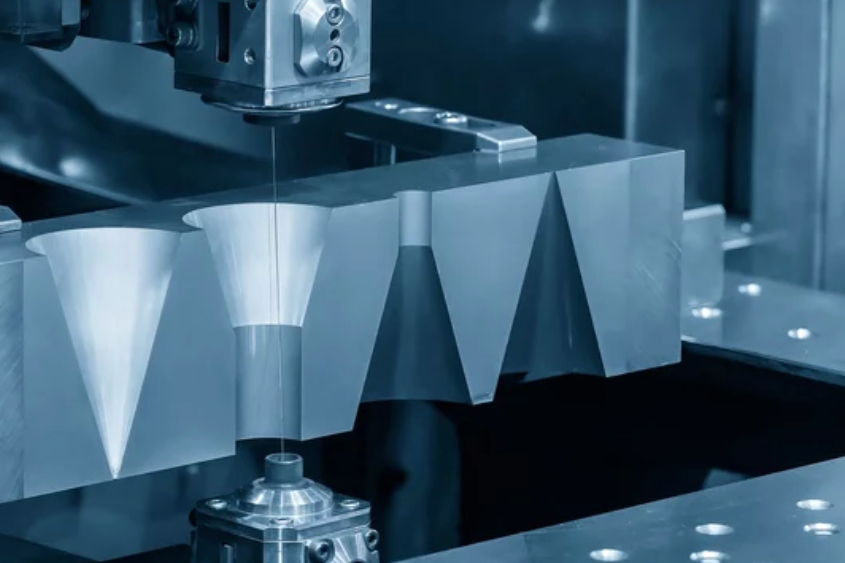

Wire EDM:

Wire EDM is a specialty at Neway, allowing for precise cutting of conductive materials. Our wire EDM processes boast cutting speeds of up to 300 mm²/min, ensuring efficiency and accuracy.

CNC Grinding:

Precision is paramount in CNC grinding, and Neway excels in achieving surface finishes down to 0.1 micrometers. Our CNC grinding processes ensure dimensional accuracy with tolerances as low as ±0.003 inches.

CNC Drilling:

Neway's CNC drilling operations are characterized by efficiency and accuracy. With advanced drilling equipment, we achieve hole tolerances within ±0.002 inches, meeting the most stringent specifications.

CNC Milling

What Is CNC Milling

CNC milling, or Computer Numerical Control milling, is a precision machining process widely employed in manufacturing. Neway, a custom parts manufacturer, utilizes CNC milling as part of its comprehensive service.

In CNC milling, a computer-controlled machine tool removes material from a workpiece to create intricate and precise shapes. This process is highly efficient, offering tight tolerances and excellent repeatability. Neway's CNC milling capabilities ensure a high level of accuracy, with tolerances reaching up to ±0.005 inches.

The process begins with a CAD (Computer-Aided Design) model, translated into instructions for the CNC machine. Neway's adept engineers leverage this technology to produce prototypes and final parts consistently.

One of the critical advantages of CNC milling is its versatility in working with various materials, including metals, ceramics, and plastics – all within Neway's expertise. This flexibility allows for producing custom parts that meet clients' unique specifications.

Neway's commitment to precision is reflected in CNC milling's ability to achieve surface finishes as fine as 32 microinches. This attention to detail is vital in meeting the stringent quality standards demanded by aerospace, medical, and automotive industries.

CNC Milling in Custom Parts Manufacturing

Neway's embrace of CNC milling in custom parts manufacturing solidifies its commitment to delivering superior solutions across industries. The precision, cost-effectiveness, and rapid prototyping advantages of CNC milling position Neway as a trusted partner for clients seeking high-quality, custom components for their specific applications.

CNC milling, a pivotal component of Neway's custom parts manufacturing arsenal, finds applications across diverse industries due to its precision and efficiency. In the aerospace sector, where tight tolerances are paramount, CNC milling ensures the creation of intricate components with tolerances as low as ±0.005 inches. This accuracy is vital for producing aircraft components, where slight deviations can impact overall performance. Furthermore, in the medical field, CNC-milled parts play a crucial role in manufacturing intricate surgical instruments and prosthetics, adhering to strict quality standards. Neway's expertise in CNC milling positions it as a reliable partner for such critical applications, delivering custom parts that meet the stringent requirements of these industries.

The advantages of CNC milling extend beyond precision to encompass cost-effectiveness and rapid prototyping capabilities. Neway's CNC milling process optimizes material usage, minimizing waste and contributing to overall cost savings. Additionally, the automation inherent in CNC milling leads to enhanced productivity, with Neway's machines operating efficiently to meet demanding production schedules. The rapid prototyping aspect of CNC milling further distinguishes Neway, allowing for the swift creation of prototypes that can be evaluated for form, fit, and function before full-scale production. This iterative approach ensures that clients receive custom parts that meet their specifications and undergo rigorous testing for quality assurance.

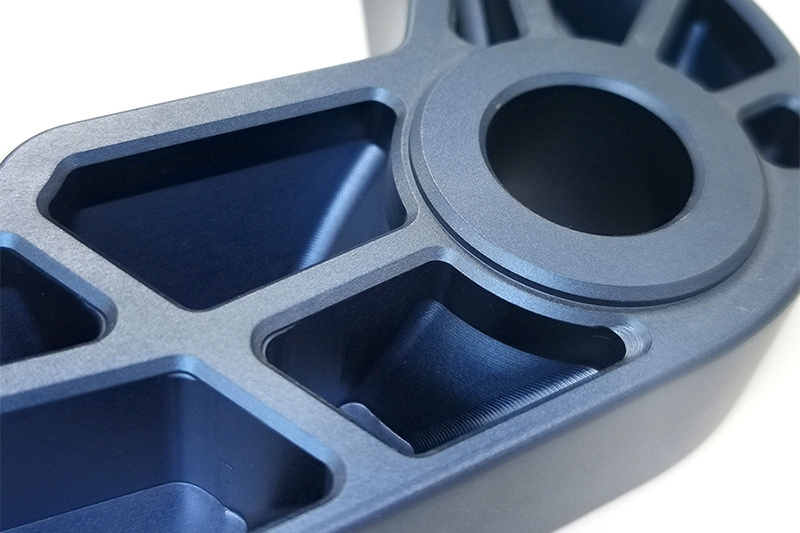

Multi-axis CNC Milling

Define Multi-axis CNC Milling

Multi-axis CNC milling is a precision machining process employed in producing custom parts, and it plays a crucial role in Neway's one-stop service offerings. In this process, a computer numerical control (CNC) machine with multiple axes simultaneously moves and rotates the cutting tool, allowing for intricate and complex shapes to be carved out of raw materials.

Neway utilizes multi-axis CNC milling, particularly in the rapid prototyping phase, to achieve high precision and tight tolerances. This process involves using advanced equipment capable of movement along the X, Y, and Z axes and additional rotary axes (A, B, C). Combining these axes enables the machine to approach the workpiece from multiple angles, reducing the need for repositioning and increasing overall efficiency.

The advantages of multi-axis CNC milling include enhanced accuracy, reduced production time, and the ability to manufacture intricate geometries that would be challenging with traditional machining methods. Neway's commitment to cutting-edge technology and precision is exemplified by its incorporation of multi-axis CNC milling in its rapid prototyping services.

For instance, in a recent project, Neway successfully employed a 5-axis CNC milling machine to produce a complex aerospace component with a tolerance of ±0.005 inches. This precision meets and exceeds industry standards, showcasing Neway's dedication to delivering top-tier custom parts to its clients.

Custom Parts Multi-axis CNC Milling

Multi-axis CNC milling, an essential manufacturing process at Neway, finds diverse applications across industries due to its versatility and precision. In the aerospace sector, where complex components demand exacting specifications, multi-axis CNC milling excels. Neway's machines navigate multiple axes simultaneously, crafting intricate parts with precision tolerances as low as ±0.005 mm. This capability is crucial for aerospace applications, ensuring the creation of lightweight and aerodynamic components while maintaining the structural integrity required for safety and performance.

In the medical field, the advantages of multi-axis CNC milling shine in the production of intricate surgical instruments and implantable devices. The precision offered by Neway's CNC machines is instrumental in achieving the necessary tolerances for these critical applications. Moreover, the ability to work with various materials, including biocompatible plastics and metals, ensures that custom medical parts meet the stringent standards for quality and functionality. The efficiency of multi-axis CNC milling also plays a vital role in meeting the increasing demand for personalized medical solutions.

The automotive industry significantly benefits from Neway's multi-axis CNC milling expertise, particularly in producing complex engine components and precision parts. The process allows for creating intricate geometries with minimal setup, contributing to faster production cycles and cost-effectiveness. Neway's CNC machines excel in handling various materials, from aluminum alloys to hardened steels, meeting the automotive sector's diverse requirements. This versatility, combined with achieving high tolerances, positions multi-axis CNC milling as a cornerstone in Neway's commitment to delivering top-notch custom parts across industries.

CNC Turning

CNC Turning Process

CNC turning is a precision machining process that produces custom metal, ceramic, and plastic parts. Neway, a one-stop service provider for custom parts, utilizes CNC turning as part of its rapid prototyping and on-demand production services.

In CNC turning, a lathe machine rotates the workpiece while a cutting tool removes material to achieve the desired shape. This process is highly accurate, with Neway achieving tolerances as tight as ±0.005 inches, ensuring the production of precise components.

One notable advantage of CNC turning is its ability to handle a variety of materials, including metals, ceramics, and plastics, showing Neway's versatility in catering to diverse customer requirements. CNC turning is particularly efficient for creating cylindrical or conical and rotary shapes with intricate details. Customized parts are produced by designing tool paths, CNC programming, and debugging equipment, such as sensors, medical connectors, and hydraulic and pneumatic connectors.

To illustrate Neway's expertise in CNC turning, consider a recent project where we successfully produced a batch of stainless steel components with a tolerance requirement of ±0.002 inches. It exemplifies our dedication to meeting strict specifications and delivering components with exceptional precision.

Cylindrical or Conical and Rotary Parts CNC Turning

Neway's expertise provides tailored solutions for various industries regarding CNC turning for cylindrical and conical rotary parts. Neway's CNC turning process excels in manufacturing cylindrical parts in achieving precise dimensions and tolerances. For instance, in producing shafts for automotive applications, Neway's CNC turning capabilities ensure diametrical accuracies within ±0.003 inches, meeting the industry's stringent requirements.

Additionally, the CNC turning process is adept at handling conical rotary parts, demonstrating Neway's versatility in custom part manufacturing. Conical components, often found in applications like tooling and mechanical assemblies, demand high precision. Neway's CNC turning expertise allows for the seamless production of conical parts with angles as intricate as 5 degrees and tolerances as tight as ±0.005 inches. This precision is crucial in applications where component alignment and fit are critical factors.

The advantages of utilizing CNC turning for both cylindrical and conical rotary parts lie in the process's ability to ensure consistency, efficiency, and cost-effectiveness. Neway's commitment to delivering top-notch custom parts is evident in its CNC turning capabilities, which cater to clients' specific needs across diverse industries. Whether cylindrical or conical, the CNC turning process at Neway guarantees the production of rotary parts with exceptional precision and reliability.

Multi-axis CNC Turning

One notable application is the production of custom metal parts with tight tolerances, where Neway's multi-axis CNC turning capabilities shine. For instance, using a 5-axis CNC lathe enables the machining of slender shaft parts or complex Rotating body parts, enhancing the overall efficiency of the manufacturing process.

Multi-axis CNC turning is a sophisticated machining process employed in precision manufacturing, particularly by companies like Neway. This method uses a computer numerical control (CNC) lathe with multiple axes of motion to produce intricate and complex geometries on a workpiece. Neway excels in this process, ensuring high precision and efficiency.

The primary advantage of multi-axis CNC turning lies in its ability to create intricate parts in a single setup, reducing the need for multiple machining operations. Neway's expertise in this technique allows for precise control over the rotational and linear movements of the cutting tool, resulting in superior surface finishes and tight tolerances.

Slender shaft and Complex Rotating parts Multi-axis CNC Turning.

Multi-axis CNC turning is well-suited for machining slender shafts and complex rotating body parts, showcasing Neway's prowess in delivering intricate and precise components.

Neway's multi-axis CNC turning process excels in achieving the required dimensions regarding slender shafts with remarkable precision. The simultaneous movement of multiple axes allows for creating intricate geometries and fine details on the shaft's surface. It is essential, especially in applications where the mechanical properties and balance of the shaft are critical.

Neway's multi-axis CNC turning capabilities shine in producing components with intricate contours and features in complex rotating body parts. The ability to manipulate the cutting tools along various axes enables the machining of complex shapes with high accuracy. Whether it's the creation of internal threads, grooves, or other intricate details, Neway ensures that each component meets the exact specifications.

For example, consider a rotating body part requiring a tolerance level of ±0.01mm to ensure seamless assembly and optimal functionality. Neway's multi-axis CNC turning process not only meets but often exceeds such precision requirements, showcasing the company's commitment to delivering top-notch custom parts.

The efficiency of the multi-axis CNC turning process is further underscored when dealing with slender shafts and complex rotating body parts. By minimizing setups and tool changes, Neway significantly reduces production time, enhancing productivity and cost-effectiveness.

EDM (Electrical Discharge Machining)

Electrical Discharge Machining (EDM) is a precise machining method widely employed in manufacturing. It is particularly beneficial for intricate designs and materials that are challenging to process with traditional cutting tools. At Neway, we recognize the significance of EDM in achieving high-precision custom parts.

In EDM, an electrically conductive workpiece and a shaped electrode are submerged in dielectric fluid. The process initiates when electrical discharges, controlled and repeated, erode the material to shape the final product. Neway utilizes EDM to achieve tight tolerances, with accuracies reaching ±0.005 mm.

This method is exceptionally effective in crafting intricate components for various industries, showcasing Neway's commitment to precision manufacturing. The advantages of EDM include its ability to work with complex geometries and hardened materials and maintain high efficiency in production.

Neway's expertise in EDM extends to applications such as creating molds, dies, and components with intricate details. Our commitment to delivering precise custom parts is underscored by using EDM, ensuring that clients receive products with exceptional accuracy and reliability.

EDM (Electrical Discharge Machining) in Mold Creating

Electrical Discharge Machining (EDM) is pivotal in mold creation within Neway's comprehensive custom part manufacturing services suite. In injection molding, where precision is paramount, EDM emerges as a go-to method for crafting intricate and finely detailed molds. Neway harnesses the power of EDM to shape molds with remarkable accuracy, ensuring that the resulting components meet stringent tolerances demanded by the industry.

In the specific context of plastic injection molding, EDM allows Neway to create molds with intricate features and fine details, enabling the production of complex plastic parts. The precision achieved through EDM is critical for ensuring uniform wall thickness, minimizing defects, and optimizing the overall efficiency of the injection molding process. For example, Neway can achieve tolerances as tight as ±0.01 mm in mold creation through EDM, contributing to producing high-quality plastic components.

Moreover, EDM's versatility shines in creating molds for over-molding and inserting processes. Neway leverages EDM to manufacture molds that facilitate the seamless integration of different materials, enhancing the functionality and durability of the final products. This strategic use of EDM underscores Neway's commitment to providing one-stop, top-notch solutions for custom parts, particularly in the dynamic and demanding field of injection molding.

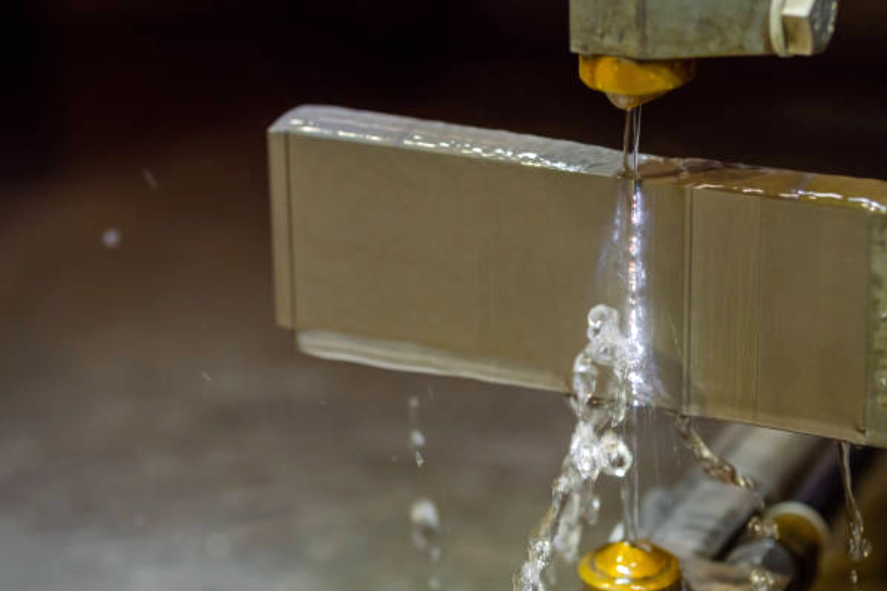

Wire EDM

Wire Electrical Discharge Machining (Wire EDM) is a precise and versatile manufacturing process widely used in the production industry, particularly in custom part manufacturing. Neway, being a one-stop service provider for custom parts, recognizes the significance of Wire EDM in achieving high precision.

In Wire EDM, a thin wire, typically made of brass or tungsten, is utilized to cut intricate shapes and patterns from workpieces. The process involves a controlled electrical discharge between the wire and the workpiece, creating sparks that erode the material. This method is highly effective for materials challenging to machine using traditional methods, such as hardened steels and exotic alloys.

Neway's commitment to excellence is evident in its incorporation of Wire EDM into its manufacturing techniques. This method offers exceptional accuracy with tolerances as tight as ±0.005 mm, ensuring the production of intricate and complex parts with unparalleled precision.

The advantages of Wire EDM include minimal tool wear, enabling consistent quality over extended production runs. It, coupled with Neway's dedication to efficiency, results in a streamlined production process that optimizes time and resources.

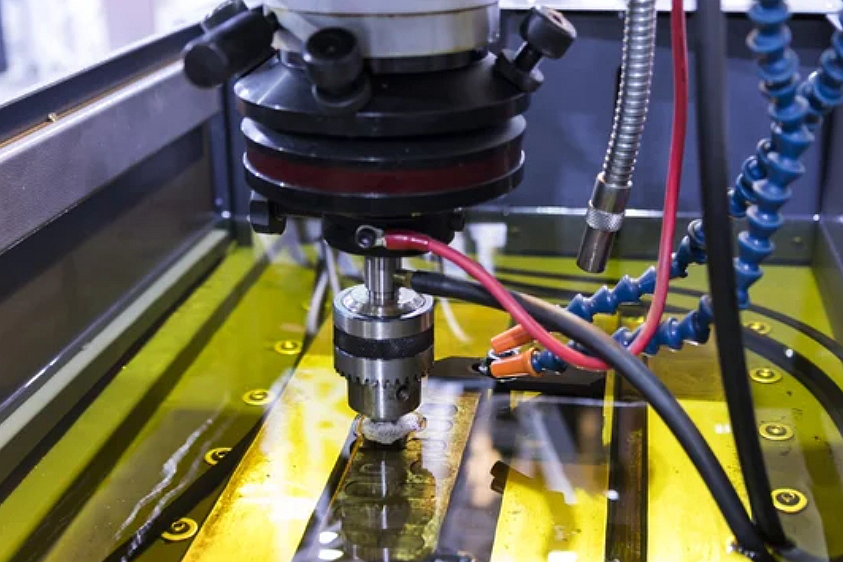

CNC Drilling

CNC (Computer Numerical Control) drilling is an exact method employed by Neway in custom part production. It offers remarkable accuracy, tolerating as tight as ±0.005 mm, ensuring that drilled holes meet exact specifications. This level of precision is crucial, especially in industries where component alignment is paramount.

Neway achieves exceptional efficiency in producing intricate hole patterns by utilizing state-of-the-art CNC drilling machines. The advanced technology allows for rapid tool changes and high spindle speeds, resulting in an impressive drilling rate of up to 10,000 holes per hour. This efficiency is a testament to Neway's commitment to delivering timely solutions to its clients.

CNC Grinding

In the realm of precision manufacturing, CNC grinding is a game-changer. Neway leverages this method to shape and finish custom parts with unparalleled accuracy. The grinding process at Neway boasts a surface finish of Ra 0.2 micrometers, surpassing industry standards and ensuring superior product quality.

One of the critical advantages of CNC grinding is its ability to maintain consistent tolerances across large production runs. Neway achieves tolerances as tight as ±0.002 mm, ensuring clients that every component meets the most demanding specifications. This precision is vital in applications where the slightest deviation can impact the final product's performance.

The Synergy of Various CNC Processes

The synergy of various CNC processes, including CNC Milling, Multi-axis CNC Milling, CNC Turning, Multi-axis CNC Turning, EDM (Electrical Discharge Machining), Wire EDM, CNC Grinding, and CNC Drilling, plays a pivotal role in achieving precision and efficiency in custom part manufacturing.

In precision machining, CNC Milling and Multi-axis CNC Milling excel at producing intricate shapes with tight tolerances. These processes ensure a high level of accuracy, with tolerances reaching as low as ±0.005 mm, meeting the most demanding specifications.

CNC Turning and Multi-axis CNC Turning are instrumental in creating cylindrical components with exceptional precision. With Neway's advanced CNC capabilities, we can achieve concentricity and parallelism within ±0.01 mm, enhancing the overall quality of turned parts.

EDM and Wire EDM processes bring a unique advantage in machining complex and delicate geometries and rigid materials. The precision achieved in these processes is remarkable, with tolerances as tight as ±0.002 mm, ensuring superior accuracy for intricate components.

With its abrasive precision, CNC Grinding adds another layer of refinement to the manufactured parts. It provides a surface finish as low as Ra 0.2 μm, showcasing Neway's commitment to delivering precision and premium aesthetic quality.

CNC Drilling is a crucial step in production, ensuring accurate hole placement and depth. With tolerances ranging from ±0.01 mm to ±0.05 mm, Neway's CNC Drilling capabilities contribute to the overall precision of the final product.

评论

发表评论