What Is Hard Metals?

Hard metals, also known as cemented or sintered carbides, are composite materials composed of hard particles, typically tungsten carbide, held together by a binder metal, usually cobalt. This combination results in a material with exceptional hardness, wear resistance, and strength.

Hard metals are crucial in Neway's manufacturing processes, especially in powder metallurgy methods like Metal Injection Molding (MIM) and Powder Compression Molding (PCM). Tungsten carbide, one of the primary hard materials used, contributes to the durability and precision of custom parts.

Hard metals commonly used by Neway in injection molding and powder compression molding include Tungsten Alloy: MIM W-Ni-Fe, MIM W-Ni-Cu, MIM W-Cu, MIM W-Ni-Co, MIM W-Fe.

Typical Tungsten Alloys and Applications?

Tungsten Carbide:

Composition: Tungsten combined with carbon in the form of tungsten carbide.

Applications: Renowned for its extreme hardness and wear resistance, tungsten carbide finds applications in cutting tools, drills, milling inserts, and wear-resistant components across industries such as machining, mining, and oil drilling.

MIM W-Ni-Fe (Tungsten-Nickel-Iron):

Composition: This blend combines tungsten, nickel, and iron.

Applications: Widely used in applications requiring high-density components with excellent magnetic properties. Examples include electromagnetic shielding components and counterweights in precision instruments.

MIM W-Ni-Cu (Tungsten-Nickel-Copper):

Composition: Tungsten, nickel, and copper from this alloy.

Applications: Ideal for parts demanding a balance between hardness and electrical conductivity. It is commonly used in electrical contacts, where durability and electrical performance are critical.

MIM W-Cu (Tungsten-Copper):

Composition: Pure tungsten and copper are blended in this composition.

Applications: Known for its exceptional thermal conductivity, MIM W-Cu is extensively used in applications such as heat sinks, electronic packaging, and components where efficient heat dissipation is crucial.

MIM W-Ni-Co (Tungsten-Nickel-Cobalt):

Composition: Tungsten, nickel, and cobalt are combined in this alloy.

Applications: Suited for high-temperature environments, MIM W-Ni-Co finds application in aerospace components, cutting tools, and other demanding settings where hardness and heat resistance are paramount.

MIM W-Fe (Tungsten-Iron):

Composition: Tungsten and iron are the primary constituents.

Applications: Valued for its cost-effectiveness and moderate hardness, MIM W-Fe is often used in various industrial applications, including automotive components and wear-resistant parts.

Forming Methods of Tungsten Alloys

Tungsten alloys, crucial for their exceptional hardness and durability, are shaped using advanced forming methods such as Metal Injection Molding (MIM) and Powder Compression Molding (PCM). In the MIM process, tungsten powder is meticulously blended with a binder, injecting a versatile feedstock into molds under high pressure to yield intricate components. Subsequent debinding and sintering stages ensure the removal of binders and the consolidation of tungsten particles, resulting in high-precision, dense final products. On the other hand, PCM offers a cost-effective alternative involving complying tungsten powder with binders using a hydraulic press. The compacted part undergoes debinding and sintering, achieving the desired density and strength.

These forming methods give Neway a competitive edge in producing tungsten alloy parts tailored to specific applications. The intricate shapes achievable through MIM and the PCM's cost-effective simplicity contribute to the manufacturing process's flexibility and efficiency. Additionally, both methods ensure that the final products meet stringent quality standards, making them ideal for applications where hardness, precision, and consistency are paramount, such as in industrial cutting tools, wear-resistant components, and electronic devices.

Tungsten Poder Injection Molding (Tungsten MIM)

Tungsten Powder Injection Molding (Tungsten MIM) is a precision manufacturing process that involves several critical steps for producing high-quality tungsten parts with intricate shapes. Here's a concise overview of the steps and advantages of Tungsten MIM:

Feedstock Preparation:

The tungsten powder used in Tungsten MIM is carefully selected for its purity and particle size distribution. The binder, often a polymer, is precisely mixed to achieve a homogeneous feedstock.

Neway's meticulous approach ensures a consistent blend, crucial for uniformity in the final product.

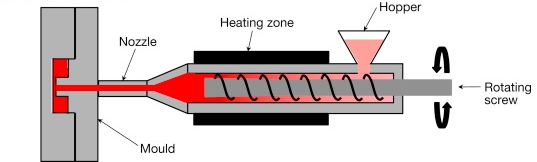

Injection Molding:

The injection molding process is carried out with precision machinery to inject the tungsten feedstock into intricate mold cavities.

Neway's state-of-the-art injection molding equipment and tooling expertise contribute to creating highly intricate shapes with minimal defects.

Debinding:

Debinding is a critical step where the molded part is heated to remove the binder. Neway employs controlled atmospheres and precise temperature profiles to eliminate the binder without compromising the part's structural integrity.

Sintering:

The rebound tungsten part undergoes sintering in a carefully controlled environment. The sintering temperature is optimized to achieve maximum densification while avoiding undesirable grain growth.

Neway's commitment to quality control ensures that each sintered part meets the specified density and mechanical properties.

Post-Processing:

Neway's expertise extends to post-processing techniques tailored to meet specific customer requirements. Whether precision machining or advanced surface treatments, Neway ensures that the final product meets the highest standards.

Further Advantages:

Enhanced Material Properties:

Tungsten MIM enables the production of tungsten parts with enhanced mechanical properties, including high hardness, excellent wear resistance, and impressive strength.

Diverse Applications:

The versatility of Tungsten MIM makes it suitable for a wide range of applications, from aerospace components to medical devices, where high density and precision are paramount.

Rapid Prototyping Capability:

Neway's integration of Tungsten MIM into its rapid prototyping services allows for quick iterations and efficient development of prototypes before moving into full-scale production.

Supply Chain Efficiency:

Tungsten MIM's suitability for small to medium production runs aligns with Neway's commitment to providing flexible and efficient solutions to its clients.

Environmental Considerations:

The material efficiency of Tungsten MIM, coupled with reduced waste generation, aligns with Neway's environmentally conscious manufacturing practices.

By expanding on these steps and advantages, it becomes evident that Tungsten Powder Injection Molding offers precision and efficiency and aligns seamlessly with Neway's commitment to delivering high-quality custom parts with a focus on innovation and sustainability.

Tungsten Poder Compression Molding (Tungsten PCM)

Tungsten Powder Compression Molding (Tungsten PCM) is a specialized process for producing tungsten components. The steps involved in Tungsten PCM are as follows:

Powder Preparation:

The success of Tungsten PCM begins with meticulous powder preparation. High-quality tungsten powder is chosen based on its purity and particle size distribution.

The blending process involves a carefully calibrated mix of tungsten powder, binders, and, in some cases, other additives to enhance the powder's flowability.

Die Filling:

The prepared tungsten powder blend is precisely introduced into the die cavity during die filling. This step demands a keen eye for detail to ensure uniform distribution and avoid any irregularities in the final product.

Advanced techniques, such as vibration or mechanical assistance, may be employed to achieve optimal powder packing.

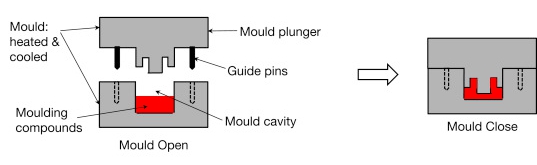

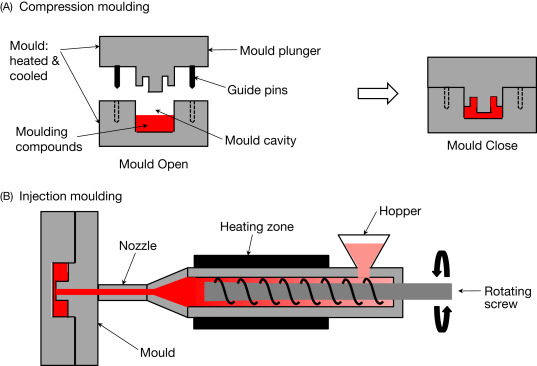

Compaction:

The heart of the process lies in compaction, where the tungsten powder experiences tremendous pressure within the die.

The high pressure consolidates the powder and significantly reduces porosity, creating a denser and more robust structure.

Sintering:

Sintering follows compaction and involves heating the compacted tungsten component in a controlled atmosphere.

The sintering process facilitates the diffusion of tungsten particles, allowing them to bond and form a cohesive structure. This step is critical for achieving the desired material properties.

Elaboration on Advantages:

High Density and Strength:

Tungsten PCM excels in producing components with unparalleled density. The high density directly translates to superior strength, making the resulting components ideal for applications where robustness is paramount.

Precision and Tight Tolerances:

The ability to achieve intricate shapes with tight tolerances sets Tungsten PCM apart. This precision is crucial in industries such as aerospace and electronics, where exact specifications are non-negotiable.

Cost-Effectiveness and Material Efficiency:

Tungsten PCM proves cost-effective due to efficient material utilization and reduced waste. The process optimizes the use of tungsten powder, minimizing costs without compromising on quality.

Consistency Across Production Runs:

Consistency is a hallmark of Tungsten PCM. The controlled nature of the manufacturing process ensures that each produced component maintains uniform properties, contributing to reliability in large-scale production.

Enhanced Mechanical Properties for Demanding Applications:

Tungsten components created through PCM exhibit exceptional mechanical properties, including high hardness and resistance to wear and corrosion.

These properties make Tungsten PCM components well-suited for demanding defense, energy, and automotive applications.

In conclusion, Tungsten PCM is a sophisticated and reliable manufacturing method that combines precision, cost-effectiveness, and consistently superior material properties. Its applications extend across industries, making it a favorable choice for producing high-performance tungsten components.

Tungsten Metal Injection Molding Vs. Powder Compression Molding

Custom Structural Complexity

In metal parts manufacturing, comparing Tungsten Metal Injection Molding (MIM) to Powder Compression Molding (PCM) involves assessing their capabilities in handling structural complexity.

Tungsten MIM is renowned for its precision and intricate detailing. It achieves a remarkable structural complexity, allowing for intricate designs with tight tolerances. The process involves mixing tungsten powder with a binding agent to create a feedstock, which is then injected into a mold. The resulting green part is then debound and sintered to achieve the final product. Tungsten MIM excels in producing complex shapes, delicate features, and high-density components.

On the other hand, Powder Compression Molding is a versatile method suitable for various materials, including tungsten. This process involves compressing a powder mixture within a mold under high pressure and subsequently sintering it. While Powder Compression Molding can achieve good dimensional accuracy, it may face challenges with intricate geometries compared to Tungsten MIM.

Regarding structural complexity, Tungsten MIM stands out for intricate designs and fine details, making it ideal for applications where precision is paramount. Powder Compression Molding, while versatile, may be better suited for less complex geometries.

Custom Parts Accuracy

When comparing Tungsten Metal Injection Molding (MIM) and Powder Compression Molding (PCM) for part accuracy, it's essential to consider the specific requirements of your application. Both processes have advantages, and the choice depends on factors like tolerance, efficiency, and the intricacy of the desired part.

Tungsten MIM is renowned for its ability to produce intricate and complex shapes with high precision. The metal powder is mixed with a binding agent, injected into molds, and then the formed components go through debinding and sintering. This process allows tight tolerances, typically reaching ±0.3% or even better. The high accuracy makes it suitable for applications where precision is paramount.

On the other hand, Powder Compression Molding is a versatile method that is particularly efficient for producing parts with moderate complexity. It involves compressing metal powders at room temperature, followed by sintering. While it may not achieve the same level of precision as MIM, PCM still offers tolerances within the range of ±1%. It makes it suitable for applications where a balance between accuracy and cost-effectiveness is crucial.

In practical terms, the choice between Tungsten MIM and PCM depends on the specific requirements of your project. If your application demands the utmost precision and complexity, Tungsten MIM might be the optimal choice. However, if you prioritize cost-effectiveness while maintaining acceptable accuracy, Powder Compression Molding could be a favorable option.

Sintered Density and Strength

Tungsten MIM is renowned for producing components with high sintered density, typically exceeding 95%. The process involves mixing tungsten powder with a binding agent, forming the green parts, and then subjecting them to debinding and sintering. The result is a robust and dense final product. In terms of strength, Tungsten MIM exhibits impressive mechanical properties, with tensile strength reaching up to 700 MPa. This makes it suitable for applications demanding precision and exceptional strength.

While offering a cost-effective solution, powder compression molding may have a slightly lower sintered density than MIM. Typically ranging between 85% and 92%, the density is influenced by powder characteristics and molding conditions. However, this process still yields parts with commendable strength. The tensile strength of PCM components can reach around 600 MPa, making it a reliable choice for applications where strength is a critical factor.

In summary, Tungsten MIM excels in high sintered density and impressive strength, making it ideal for applications requiring robust and intricate parts. On the other hand, Powder Compression Molding offers a cost-effective alternative with good strength, though the sintered density may be slightly lower.

Internal Uniformity

Examining the internal uniformity of components produced through Tungsten Metal Injection Molding (MIM) and Powder Compression Molding (PCM) provides insights into the structural integrity of the final products.

In Tungsten MIM, the process involves creating intricate shapes by injecting a tungsten powder and binder mixture into molds, followed by debinding and sintering. This method typically results in excellent internal uniformity, ensuring consistent density and structure throughout the component. The controlled sintering process contributes to a uniform distribution of tungsten particles, minimizing porosity and enhancing the overall integrity of the part.

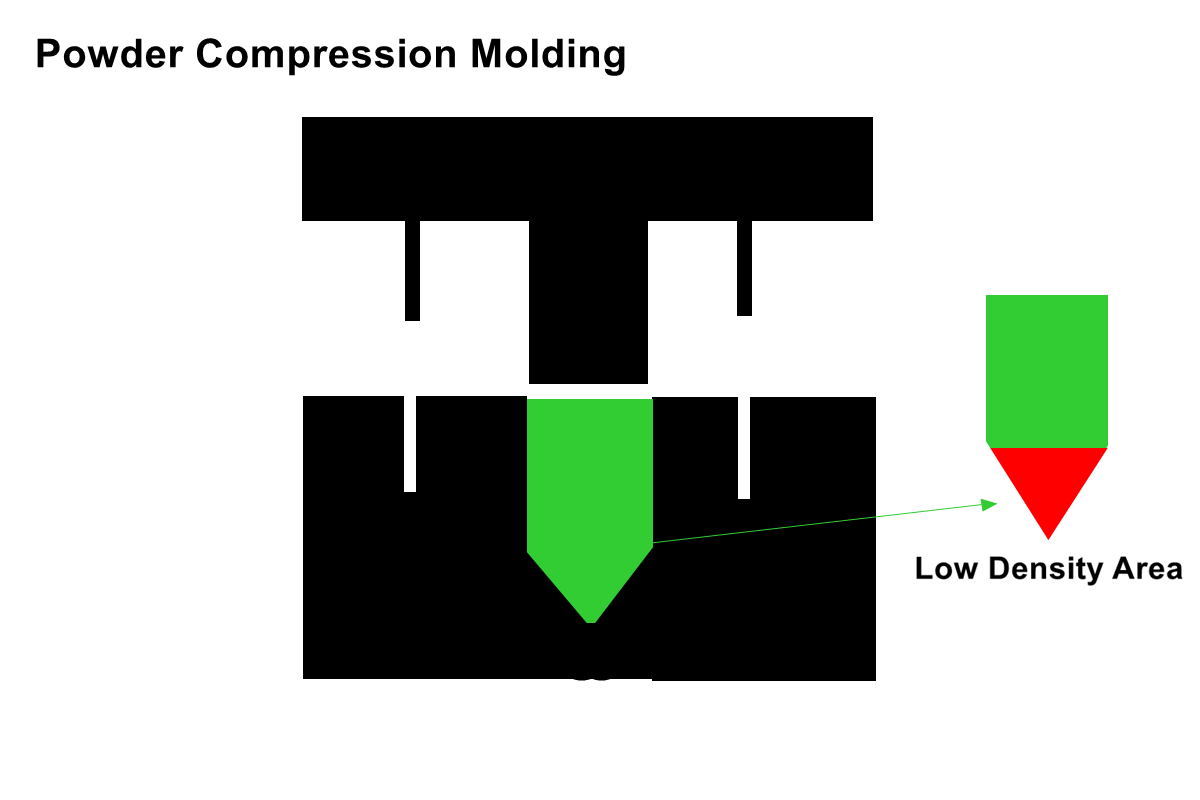

Powder Compression Molding, while a cost-effective alternative, may exhibit slightly lower internal uniformity than MIM. The compression molding process involves pressing metal powders at room temperature before sintering. Powder characteristics and molding conditions can influence the degree of uniformity. However, with proper control and optimization, PCM can still produce components with acceptable internal uniformity for many applications.

Powder compression molding is prone to pressure differences when manufacturing tungsten alloy parts with a taper and uneven stress structures. The density of the tip of the part is smaller, which reduces its physical properties. For example, the nozzles, thimbles, and other tips produced by MIM are more wear-resistant than those produced by PCM.

In practical terms, the choice between Tungsten MIM and PCM depends on the specific requirements of your project. If internal uniformity is critical, particularly for intricate and complex parts, Tungsten MIM might be the preferred option. Neway's expertise in metal injection molding ensures that the components exhibit the desired internal uniformity, meeting stringent precision standards.

Mold Cost Comparison

Tungsten MIM typically involves the creation of intricate molds to shape components with precision. The molds used in MIM can be more complex due to the detailed designs achievable through this process. Consequently, the mold cost for Tungsten MIM may be higher compared to other molding methods. However, weighing this against the advantages of producing highly detailed and precise parts is crucial.

On the other hand, Powder Compression Molding tends to have lower mold costs. The molds for PCM are more straightforward as the process involves compressing metal powders into the desired shape. The simplicity of the molds contributes to cost savings, making PCM an economically attractive option for specific applications where intricate details are not a primary requirement.

In the context of Neway's services, the choice between Tungsten MIM and PCM would depend on the specific needs of your project and the balance between precision and cost-effectiveness. Neway's expertise in both methods allows for a tailored approach based on your project requirements.

Mass Production Efficiency

Tungsten MIM is well-suited for mass production of intricate and complex parts with high precision. The process involves injecting a tungsten powder and binder mixture into molds, debinding, and sintering. While the setup and tooling for MIM may take some time initially, the production efficiency is high once in place. Tungsten MIM allows for the production of large quantities of components with consistent quality, making it efficient for mass production.

Powder Compression Molding, a more straightforward process, is also efficient for mass production, especially for moderately complex parts. The compression molding of metal powders at room temperature, followed by sintering, allows for a faster production cycle. While the setup may be quicker than MIM, the overall efficiency is influenced by the parts' simplicity.

In the context of Neway's capabilities, both Tungsten MIM and PCM offer efficient solutions for mass production. The choice between the two would depend on the specific requirements of your project, including the intricacy of the parts, desired precision, and overall production volume.

How To Select The Tungsten Parts Manufacturing Method

Selecting the appropriate Tungsten parts manufacturing method is a crucial decision that depends on various factors. Let's explore the key considerations to help you make an informed choice:

Part Complexity:

Metal Injection Molding (MIM): Ideal for intricate and complex parts with detailed features. The MIM process allows for high precision and intricate designs.

Powder Compression Molding (PCM) is suitable for moderately complex parts. While not as detailed as MIM, PCM offers a cost-effective solution for specific applications.

Precision and Tolerance:

MIM: Known for achieving high precision with tight tolerances, making it suitable for applications where accuracy is paramount.

PCM: Offers acceptable precision with good tolerances, making it a balanced choice for applications where cost-effectiveness is a priority.

Sintered Density and Strength Requirements:

MIM: Results in high sintered density exceeding 95%, providing robust components with impressive strength, suitable for demanding applications.

PCM: While slightly lower in sintered density, PCM still delivers components with commendable strength, making it a reliable choice for various applications.

Internal Uniformity:

MIM: Exhibits excellent internal uniformity due to the controlled sintering process, ensuring consistent density and structural integrity.

PCM: Offers good internal uniformity, although it may not match the level of intricacy achieved through MIM.

Mold Cost and Complexity:

MIM: Involves more complex molds, potentially leading to higher initial mold costs. However, the investment may be justified for precision and complexity requirements.

PCM: Features simpler molds, resulting in lower initial mold costs, making it an economically attractive option for specific applications.

Production Volume:

MIM: Efficient for mass production of intricate parts once the initial setup and tooling are in place.

PCM is also suitable for mass production, particularly for parts with moderate complexity, and offers a quicker setup than MIM.

Considering Neway's expertise in Tungsten Metal Injection Molding and Powder Compression Molding, you can rely on their one-stop service for custom parts, ensuring a tailored approach based on your specific project requirements. If you have specific criteria or examples you'd like to discuss, please provide them for a more detailed and personalized recommendation.

评论

发表评论