Custom thermoplastic parts play a pivotal role in various industries, offering versatility and durability in various applications. From automotive components to medical devices, these parts are integral to the functionality of countless products. However, achieving the perfect custom thermoplastic part requires selecting the proper manufacturing method. This blog will explore the various manufacturing methods for custom thermoplastic parts and discuss Neway's expertise in this field.

Brief Overview of Custom Thermoplastic Parts

Custom thermoplastic parts are precisely engineered components designed to meet the unique needs of different industries. These parts are made from thermoplastic materials, with distinct characteristics that make them ideal for customization. Thermoplastics can be melted and reshaped multiple times without losing their properties, offering exceptional flexibility in design and functionality.

Selecting the appropriate manufacturing method is critical in producing custom thermoplastic parts. It directly impacts the quality, cost, and efficiency of the parts. The correct method ensures that the final product meets the required specifications and performs its intended function effectively.

Neway, a leading custom metal, ceramic, and plastic parts manufacturer, has established itself as a trusted name in the industry. With a comprehensive understanding of various manufacturing methods, Neway excels in producing custom thermoplastic parts. Their commitment to quality and innovation has made them a preferred choice for businesses seeking high-quality custom components.

Understanding Thermoplastics

Definition and Properties of Thermoplastics

Thermoplastics are a class of polymers with unique characteristics that set them apart in custom part manufacturing. These materials can be melted and reformed multiple times without undergoing chemical changes. This property, known as thermoplasticity, enables manufacturers to shape them into intricate designs.

Thermoplastics exhibit various properties, including excellent chemical resistance, high impact strength, and the ability to maintain their mechanical properties across a wide temperature range. Moreover, they are lightweight and quickly colored, making them suitable for various industries.

Common Applications of Thermoplastic Parts

The versatility of thermoplastic parts extends to a wide array of applications, making them indispensable in industries such as automotive, aerospace, electronics, healthcare, and consumer goods. These parts are used in making anything from lightweight automotive components to intricate medical device housings. Their applications are limited only by imagination and engineering expertise.

The popularity of thermoplastics in custom part manufacturing is no coincidence. Its flexibility, combined with its unique properties, makes it an ideal choice. Manufacturers can easily adjust the design, iterate prototypes, and produce custom parts efficiently. This adaptability ensures that thermoplastic parts can meet the ever-evolving requirements of different industries.

Manufacturing Methods for Custom Thermoplastic Parts

Custom thermoplastic parts can be manufactured using various techniques, each offering distinct advantages and limitations. Here, we'll explore some of the most common methods for producing these parts and provide real-world examples to illustrate their application.

Injection Molding

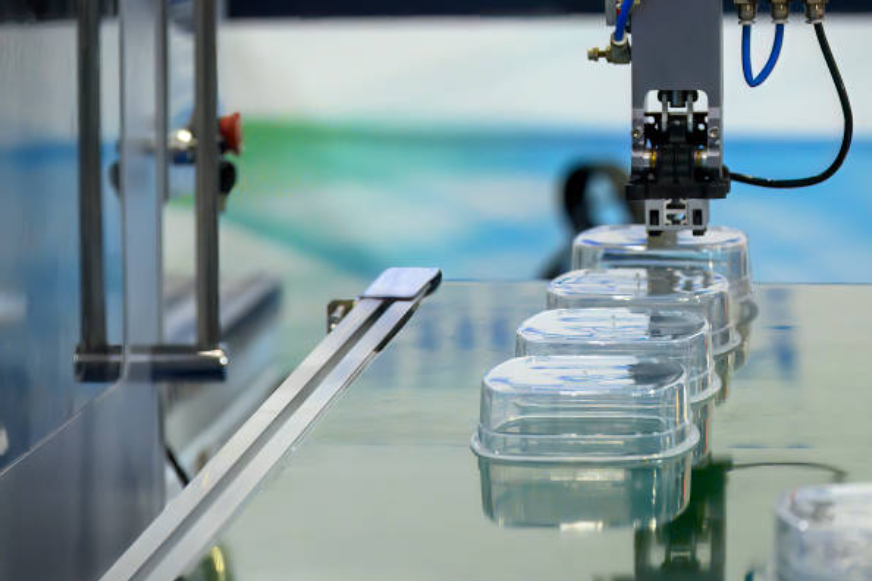

Explanation of the Injection Molding Process

Injection molding is a widely used manufacturing method for custom thermoplastic parts. It involves melting thermoplastic material and injecting it into a mold cavity. The mold is opened once the material cools and solidifies, and the final part is ejected. This method is known for its precision and repeatability, making it suitable for high-volume production.

Advantages and Limitations of Injection Molding

Injection molding offers precise control over part dimensions, surface finish, and material properties. It's cost-effective for large production runs but may have higher setup costs. Limitations include longer lead times for tooling and the need for substantial initial investment.

Using injection molding to produce custom plastic parts must be proven for mass production. Because the cost of injection molds is high, it is difficult to change the structure once the mold is made. However, plastic injection molds can quickly produce consistent, high-precision plastic parts. It is the preferred process for mass production of plastic parts.

Thermoplastics | |||

Real-World Examples of Thermoplastic Parts Made Through Injection Molding

Neway's expertise in injection molding has produced various custom thermoplastic parts, such as intricate automotive components, medical device enclosures, and consumer product casings. This method ensures that parts are consistent in quality and meet the desired specifications.

Overmolding and Insert Molding

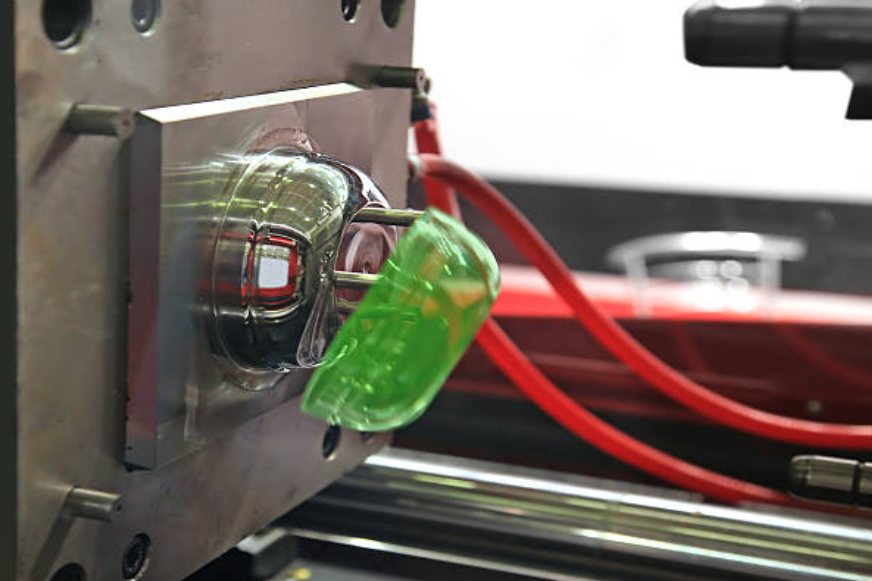

Explanation of Overmolding and Insert Molding

Overmolding and insert molding are specialized techniques used in custom thermoplastic parts manufacturing. Overmolding manufacturing involves adding a second material (often elastomers or thermoplastic rubber) over a base thermoplastic part. Insert molding manufacturing, on the other hand, involves inserting a component, like a metal insert, into the mold before the thermoplastic material is injected. These methods enable the creation of composite parts with diverse properties.

Benefits of These Methods for Custom Parts

Overmolding and insert molding offer several advantages. They enhance the durability and functionality of parts, providing features like improved grip, vibration dampening, and electrical insulation. These methods also allow for innovative and complex designs.

Case Studies Showcasing Over-Molded and Insert-Molded Thermoplastic Components

Neway has successfully used overmolding and insert molding to create custom thermoplastic parts for industries such as electronics and healthcare. For example, they have produced ergonomic and slip-resistant hand grips for handheld medical devices, ensuring user comfort and safety. These methods have been instrumental in enhancing product performance and customer satisfaction.

CNC Machining for Thermoplastics

Overview of CNC Machining in Thermoplastic Part Production

Plastic CNC (Computer Numerical Control) machining is a subtractive manufacturing process for creating custom thermoplastic parts. It involves cutting and shaping thermoplastic materials using computer-controlled machines. This method is known for its precision and the ability to produce highly customized parts.

Precision and Customization Options Offered by CNC Machining

CNC machining allows for intricate and precise designs. It can create parts with tight tolerances and complex geometries. This level of customization is precious for industries with unique requirements, such as aerospace and electronics.

Custom parts CNC Machining has a wide range of applications. Compared with 3D printing, CNC-machined plastic parts have higher precision and are suitable for producing prototypes and small and medium-sized batches of custom plastic parts.

Success Stories of CNC-Machined Thermoplastic Parts

Neway's expertise in CNC machining for thermoplastics has led to creating specialized components. For example, they have produced precise gears for intricate mechanical systems and bespoke prototypes for research and development. The ability to deliver high-precision components has made CNC machining a preferred choice for industries that demand accuracy.

Vacuum Forming and Thermoforming

Introduction to Vacuum Forming and Thermoforming

Vacuum forming and thermoforming are thermoforming processes used to produce custom thermoplastic parts. These methods involve heating a thermoplastic sheet until it's pliable, then forming it over a mold using vacuum pressure. Both methods are suitable for creating parts with large surface areas and specific design needs.

Applications and Design Possibilities with These Methods

Vacuum forming and thermoforming offer a cost-effective way to create parts with intricate details and varying wall thicknesses. They are ideal for producing product enclosures, packaging, and custom signage. Their versatility makes them an excellent choice for industries with diverse design requirements.

Compared to plastic injection molding, vacuum molding is also suitable for mass production of customized plastic parts. However, it cannot achieve the accuracy of injection-molded parts or manufactured parts with high precision requirements. Most vacuum molding parts have larger R angles.

Examples of Thermoplastic Products Manufactured Using These Techniques

Neway has harnessed the potential of vacuum forming and thermoforming to produce a wide range of custom thermoplastic parts. Their portfolio includes custom panels for industrial machinery, protective covers for electronics, and unique packaging solutions for consumer products. These methods have enabled Neway to offer innovative and cost-effective solutions to their clients.

3D Printing with Thermoplastics

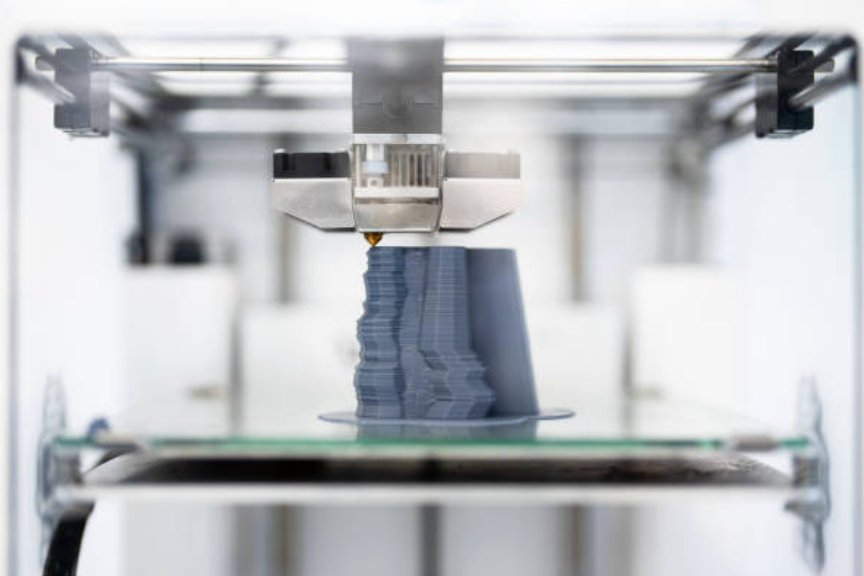

Explanation of 3D Printing as a Modern Manufacturing Method

3D printing, or additive manufacturing, is a cutting-edge custom thermoplastic part production process. It involves building parts layer by layer, guided by digital design files. This method is known for its rapid prototyping capabilities and the ability to create complex geometries.

Benefits, Speed, and Complexity of 3D-Printed Thermoplastic Parts

3D printing offers several advantages, including shorter lead times, reduced material waste, and the ability to produce prototypes and low-volume batches cost-effectively. It's well-suited for highly customized parts, and its layer-by-layer construction allows for intricate and complex designs that may be challenging with traditional methods.

Compared with CNC machining, 3D printing custom thermoplastic parts has a lower range of material choices and lower precision. However, the structural complexity of the parts that can be realized is relatively high. And the efficiency is high. Capable of rapid prototyping. Is the structure The preferred process for prototyping complex parts?

Showcasing Innovative Thermoplastic 3D-printed Items

Neway has embraced 3D printing with thermoplastics to deliver innovative solutions to their clients. They have produced intricate, lightweight parts for aerospace, medical implants, and consumer products. This method's ability to create intricate, customized, and often lightweight components has been instrumental in meeting the evolving demands of various industries.

The Role of Neway in Custom Thermoplastic Parts

Neway's Expertise in Custom Thermoplastic Manufacturing

Neway, a renowned custom metal, ceramic, and plastic parts manufacturer, has extended its expertise to custom thermoplastic production. With years of experience and a commitment to quality, Neway has established itself as a leading name in the industry. They deeply understand the intricacies of custom thermoplastic manufacturing, ensuring that their clients receive top-tier components.

How Neway Utilizes Various Methods to Meet Customer Demands

One of the critical strengths of Neway lies in its ability to offer a wide range of manufacturing methods to cater to diverse customer demands. Neway can deliver on all fronts, whether it's injection molding for high-volume production, CNC machining for precision components, or 3D printing for rapid prototyping. Their flexible approach ensures that each project is handled with the most suitable method, guaranteeing the best results.

Success Stories and Customer Testimonials

The accurate measure of a manufacturer's excellence lies in the satisfaction of its clients. Neway's success stories are a testament to their commitment to quality and innovation. Customers from various industries have shared their positive experiences, highlighting the superior quality, timely delivery, and cost-effectiveness of the custom thermoplastic parts provided by Neway.

How To Select The Right Manufacturing Process

Selecting the proper manufacturing process is crucial for custom thermoplastic parts. Here, we will explore the considerations that should guide your decision and compare the advantages of different methods. By the end of this section, you'll better understand how to choose the proper manufacturing method for your custom plastic parts.

Considerations When Choosing the Manufacturing Process

Quantity and Volume: The required quantity of parts plays a significant role in the choice of the manufacturing method. High-volume production is often best suited to injection molding, while lower volumes can be efficiently handled with 3D printing or CNC machining.

Part Complexity: Consider the complexity of the design. If your parts have intricate geometries or features, 3D printing or CNC machining may be the way to go. For simpler designs, injection molding or thermoforming can be efficient.

Material Properties: Different manufacturing methods work better with specific thermoplastic materials. When choosing, consider the material's properties, including strength, temperature resistance, and chemical compatibility.

Lead Time: The urgency of your project is a critical factor. Some methods, like 3D printing, offer shorter lead times for prototyping and small runs, while processes like injection molding may require more time for tooling.

Compare the Advantages of Different Manufacturing Methods

Injection Molding: Advantages include high production speed, low per-unit cost in high volumes, and excellent material properties. However, it may have longer setup times and higher initial tooling costs.

3D Printing: 3D printing offers rapid prototyping, design flexibility, and low waste. It's ideal for small runs and complex geometries but may be less cost-effective for large production volumes.

CNC Machining: CNC machining provides high precision and can be used for various thermoplastic materials. It's suitable for low to medium production volumes and offers excellent quality.

Vacuum Forming and Thermoforming: These methods are cost-effective for large surface area parts and offer excellent design possibilities. They are handy for industries like packaging and signage.

Choosing the Proper Manufacturing Method for Your Custom Plastic Parts

In conclusion, the choice of manufacturing method should align with your project's unique requirements. Whether you require high-volume production, intricate designs, or rapid prototyping, Neway's expertise in custom thermoplastic manufacturing ensures you receive the best possible solution.

Neway's commitment to quality, innovation, and flexibility in manufacturing methods makes it an ideal partner for any project involving custom thermoplastic parts. By understanding the considerations and advantages of different methods, you can confidently select the manufacturing process that suits your needs, knowing Neway has the expertise to deliver exceptional results.

评论

发表评论