Neway is a premier Tungsten Metal Injection Molding (MIM) Parts Insert Molding Supplier, excelling in precision engineering and one-stop custom manufacturing. Leveraging cutting-edge technologies like MIM and Insert Molding, we specialize in crafting intricate electrical contact pins. Our expertise extends to various manufacturing methods, including die casting, metal stamping, and laser cutting. As a trusted industry leader, Neway ensures the highest quality from powder injection to sintering, delivering impeccable powder metallurgy products.

The MIM blank parts we manufacture can reach ISO 2768-F accuracy, and the overall part accuracy, including insert molding, can reach ISO 2768-M tolerance requirements.

ISO 2768 Tolerance Class Designation (Description) | ||||

Permissible deviations in mm for ranges in nominal lengths | (fine) | m(medium) | (coarse) | (very coarse) |

0.5 up to 3 | 0.05 | 0.1 | 0.2 | 0.5 |

over 3 up to 6 | 0.05 | 0.1 | 0.3 | 1 |

over 6 up to 30 | 0.1 | 0.2 | 0.5 | 1.5 |

over 30 up to 120 | 0.15 | 0.3 | 0.8 | 2.5 |

over 120 up to 400 | 0.2 | 0.5 | 1.2 | 土4.0 |

over 400 up to 1000 | 0.3 | 0.8 | 土2.0 | 土6.0 |

over 1000 up to 2000 | 0.5 | 1.2 | 3 | 8 |

over 2000 up to 4000 | - | 2 | 土4.0 | |

Importance of MIM Tungsten Electrical Contact Pins In Energy Industries

Tungsten electrical contact pins are pivotal in the energy sector due to their exceptional properties. Renowned for high melting points and superior conductivity, these pins ensure robust performance in challenging environments. As a leading Tungsten MIM Parts Insert Molding Supplier, Neway contributes significantly to the energy industry by delivering precision-crafted electrical contact pins. Our expertise in MIM technology and advanced molding engineering ensures the production of durable and reliable components crucial for power transmission and distribution systems. As energy industries demand heightened efficiency and durability, Tungsten electrical contact pins from Neway emerge as indispensable components, ensuring seamless operations and longevity in critical applications.

Definition of MIM Technology

Metal Injection Molding (MIM) technology represents a cutting-edge approach to custom part manufacturing. MIM involves the combination of fine metal powders and binders, creating a feedstock that undergoes injection molding. This innovative process allows for the production of highly complex and precise components.

Key features and advantages of MIM

Metal Injection Molding (MIM) is a versatile manufacturing process offering significant advantages, especially in creating custom tungsten parts. Due to the extremely high hardness and melting point of tungsten alloy, it cannot be processed by traditional casting, CNC machining, and other processes. MIM is the most suitable for processing highly complex parts. High-quality tungsten alloy parts. It has the following advantages:

Complex Geometries: MIM allows for intricate designs and complex geometries that might be challenging or impossible to achieve through traditional machining. Tungsten parts with intricate shapes or fine details can be accurately replicated using MIM.

High Precision: MIM offers exceptional precision, delivering tight tolerances and high accuracy in reproducing intricate features. It is crucial for applications where precision is paramount, such as electrical contact pins. The precision of tungsten alloy electrical contact pins manufactured by Neway follows the tolerance standard of ISO2768 F.

Material Versatility: MIM supports a wide range of materials, including tungsten and its alloys, such as tungsten-copper alloy, tungsten-iron alloy, tungsten-nickel alloy, tungsten-cobalt alloy, etc. It enables specialized alloys or materials with unique properties required for specific applications, ensuring optimal final part performance.

Neway can also customize tungsten alloy powder according to customer needs to meet the requirements of the final part.

Cost-Effectiveness: The process minimizes material waste and reduces the need for secondary operations, leading to cost savings in production. MIM provides a cost-effective alternative for tungsten parts, which can be expensive to manufacture using traditional methods.

Scalability and Consistency: MIM is highly scalable, allowing for the production of large quantities of tungsten parts with consistent quality. The MIM process has a high geometric complexity and high consistency of injection molding, which can ensure high consistency of products in batch delivery.

Reduced Lead Times: Compared to traditional manufacturing methods, MIM typically has shorter lead times, making it advantageous for projects that require rapid production and delivery of tungsten parts.

Minimal Finishing Requirements: MIM often produces near-net-shape parts, reducing the need for extensive post-processing or finishing operations. For tungsten components, this minimizes the risk of material degradation or alteration.

Customization and Design Freedom: MIM allows flexibility and customization, enabling engineers to optimize tungsten parts for specific applications, enhancing their functionality and performance.

Metal Injection Molding (MIM) is a versatile manufacturing process offering significant advantages, especially in creating custom tungsten parts. Due to the extremely high hardness and melting point of tungsten alloy, it cannot be processed by traditional casting, CNC machining, and other processes. MIM is the most suitable for processing highly complex parts. High-quality tungsten alloy parts. It has the following advantages:

In the realm of electrical contact pins, precision is paramount. MIM technology shines in this regard, enabling the creation of intricate shapes and ensuring tight tolerances essential for the functionality of these components. The versatility of MIM extends to various materials, making it an ideal choice for the nuanced requirements of Tungsten MIM parts.

The Role of MIM Tooling

Molding engineering is pivotal in the journey from concept to the final product. It involves the application of engineering principles to the design and optimization of molds and processes used in part manufacturing. In Tungsten MIM parts, molding engineering is critical in achieving the desired precision and functionality.

For Tungsten MIM parts, the challenges and intricacies are unique. Molding engineers at Neway navigate these challenges by leveraging their expertise in material science, fluid dynamics, and thermodynamics. This interdisciplinary approach ensures that the molding process is not just a means to an end but a crucial contributor to the quality of electrical contact pins.

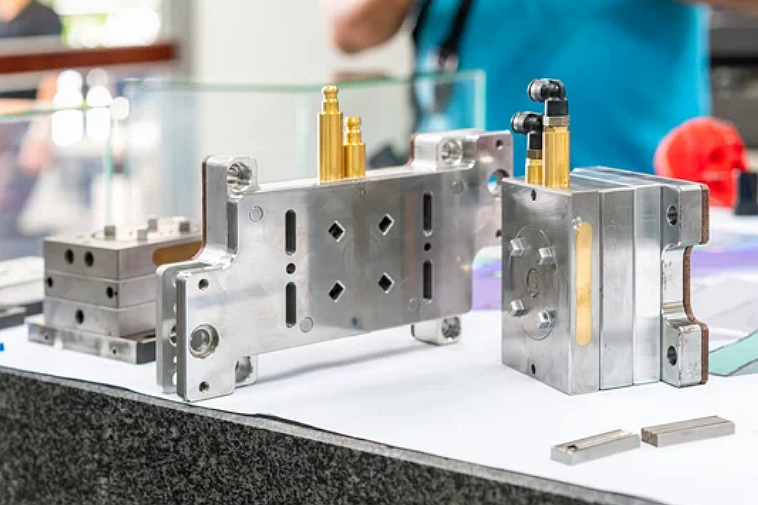

MIM tooling is the backbone of the Metal Injection Molding process. These precision molds are crafted with meticulous detail to shape the feedstock into the desired form. The molds, typically made from tool steel, must withstand high temperatures and pressures during the injection molding, highlighting the importance of robust and precise tooling.

In the production of Tungsten MIM parts, precision is non-negotiable. The ability to create intricate designs and maintain tight tolerances relies heavily on the quality of the MIM tooling. Neway's commitment to excellence is evident in its state-of-the-art tooling capabilities, ensuring that each electrical contact pin meets the stringent standards required for optimal performance.

Powder Metallurgy Sintering Process

Powder metallurgy sintering is a fundamental step in producing Tungsten MIM parts. It involves subjecting the molded parts to high temperatures in a controlled atmosphere. The metal powders fuse during this process, creating a dense and durable structure. For Tungsten MIM parts, the powder metallurgy sintering process is instrumental in achieving the desired mechanical and electrical properties.

In the context of Tungsten MIM parts, the sintering process is a transformative stage. It imparts strength and integrity to the components, ensuring they can withstand the rigors of their intended applications. Neway's commitment to excellence is evident in its meticulous control of the sintering parameters, resulting in Tungsten MIM parts that meet the highest industry standards.

Precision is paramount in producing electrical contact pins, and the powder metallurgy sintering process is crucial. By carefully calibrating the sintering parameters, Neway ensures that each Tungsten MIM part undergoes a controlled transformation, emerging with the exact dimensions and material properties required for optimal performance in electrical applications.

Insert Molding Process

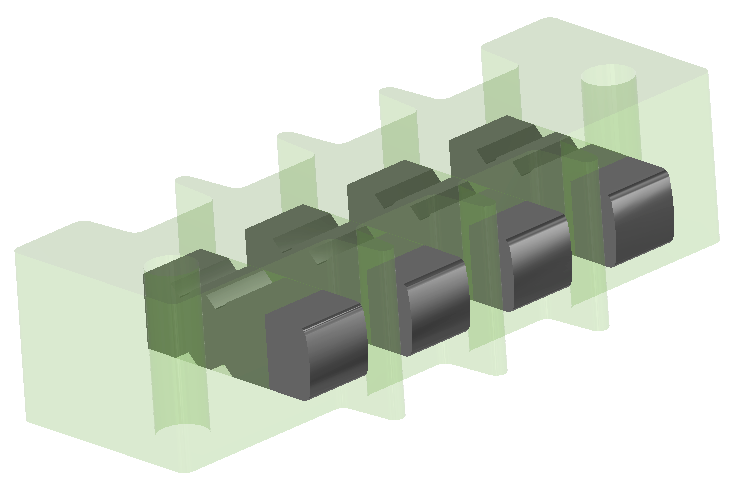

Insert molding is a specialized process that involves placing pre-formed components, known as inserts, into the mold before injecting the molten material. This technique is particularly advantageous in the production of Tungsten MIM parts, allowing for the integration of inserts with precision and efficiency.

Thermoplastics | Thermosets | |||

Medical-Grade silicone rubber | ||||

Optical silicone rubber | ||||

For electrical contact pins, where intricate geometries and precise configurations are crucial. Neway's expertise in insert molding ensures that the electrical components are seamlessly integrated, providing enhanced structural integrity and functionality.

Although insert molding is a relatively mature two-shot injection molding process, Neway still guarantees compliance with the tolerance requirements of ISO 2768 F and offers a variety of material options.

The benefits of insert molding in Tungsten MIM parts production extend beyond incorporating electrical components. This method enhances the overall structural integrity of the parts, reduces assembly steps, and allows for the creation of complex geometries that might be challenging with traditional manufacturing methods.

Exploring Insert Molding for Electrical Contact Pins in the Energy Industry and E-mobility

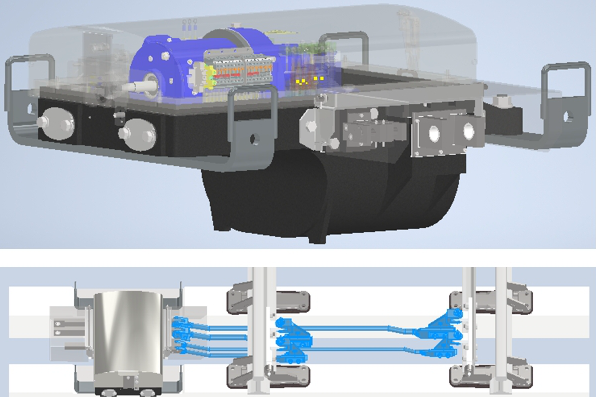

In the dynamic landscape of the energy industry, the demand for reliable and efficient components is paramount. Tungsten alloy-inserted molded electrical contact pins have become critical players in enhancing connectivity within power generation, distribution, and storage systems.

Grid Connectivity:

Tungsten MIM parts, mainly electrical contact pins, ensure seamless grid connectivity. The precision achieved through insert molding guarantees secure connections in critical components, contributing to the overall reliability of power distribution networks.

Renewable Energy Applications:

In the realm of renewable energy, where components are exposed to challenging environmental conditions, Tungsten MIM parts demonstrate exceptional resilience. Insert molding reinforces electrical contact pins, ensuring they withstand the rigors of wind, solar, and hydroelectric power generation.

Powering the Future of E-mobility

The electrification of transportation, commonly known as E-mobility, presents unique challenges that demand innovative solutions. Tungsten alloy-inserted molded electrical contact pins emerge as a critical component in this transformative industry.

Electric Vehicles (EVs):

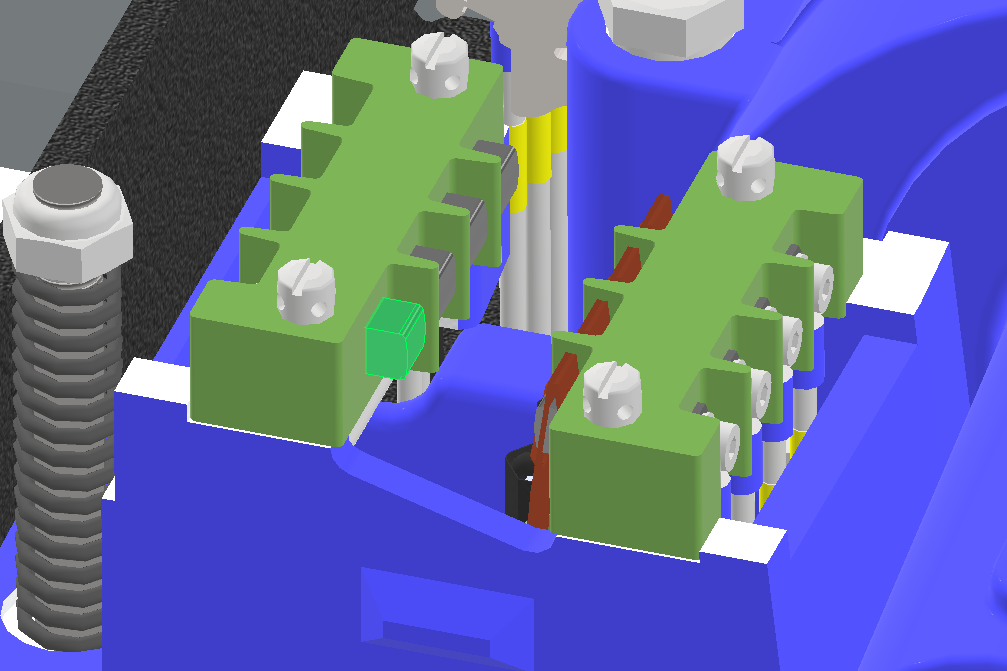

Tungsten's high melting point and durability make it an ideal material for electrical contact pins in EVs. The insert molding process ensures a secure and robust connection in the intricate electrical systems of electric vehicles, contributing to their efficiency and longevity.

Charging Infrastructure:

The reliability of charging infrastructure is pivotal for the widespread adoption of E-mobility. Tungsten MIM parts, crafted through precision insert molding, guarantee the integrity of electrical contact pins in charging stations. This reliability is fundamental for the seamless charging experience of electric vehicles.

Advantages of Neway's Expertise in Tungsten MIM Parts Insert Molding

Neway's proficiency in Tungsten Metal Injection Molding (MIM) sets it apart as a leader in the manufacturing industry. Leveraging state-of-the-art technology, our MIM process allows for producing intricate and complex Tungsten components with unparalleled precision. MIM technology involves mixing finely powdered Tungsten with a binding agent to create a feedstock, which is then injected into molds using specialized equipment. This process enables the cost-effective production of small, intricate parts with high strength and density, making it an ideal solution for applications where traditional manufacturing methods fall short.

One of the critical advantages of Neway's expertise in Tungsten MIM is the ability to incorporate insert molding seamlessly. Through our meticulous molding engineering, we integrate metal inserts into the Tungsten components during the MIM process, enhancing structural integrity and functionality. This unique approach ensures that our Tungsten MIM parts exhibit exceptional mechanical properties, making them well-suited for demanding aerospace, medicine, and electronics applications. The precision achieved in insert molding reinforces the parts and allows for creating multifaceted designs that would be challenging to achieve through other manufacturing methods.

In addition to the technical prowess in Tungsten MIM and insert molding, Neway's commitment to the powder metallurgy sintering process further elevates the quality of our products. The carefully controlled sintering process results in Tungsten MIM parts with superior density and homogeneity, contributing to their excellent mechanical and thermal properties. This level of detail in the manufacturing process exemplifies Neway's dedication to delivering top-notch powder metallurgy products. As a leading MIM parts manufacturer, our innovative approach to Tungsten insert molding meets and exceeds the expectations of industries demanding precision, durability, and reliability in their components.

评论

发表评论