What Is Anodizing Cast Aluminum

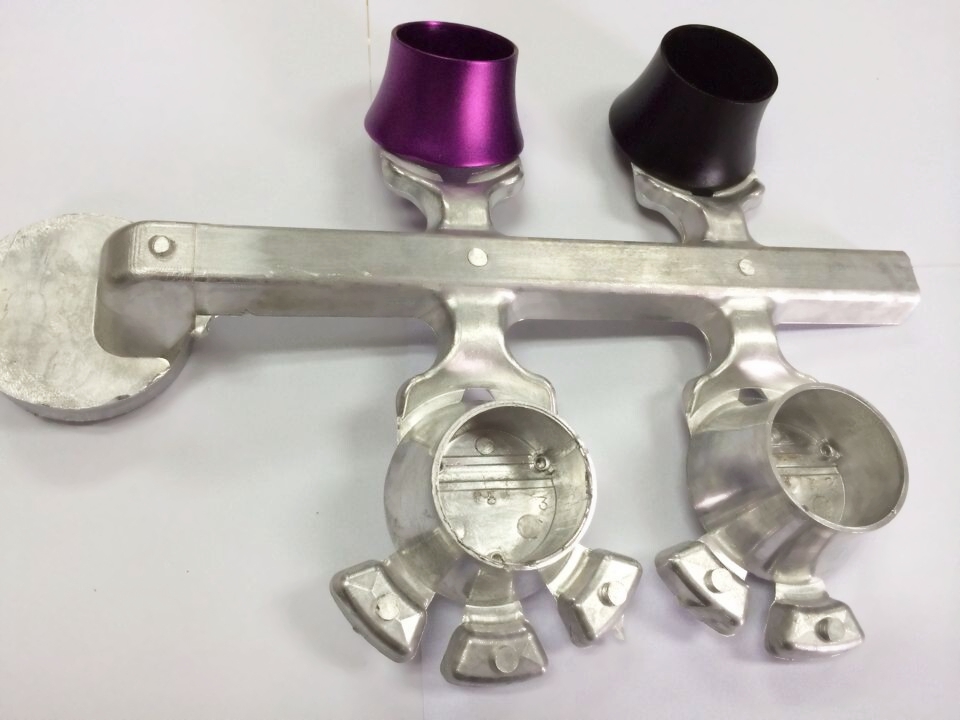

In precision casting, including die casting, sand casting, and gravity casting, the process typically involves melting aluminum alloy, injecting or pouring it into a mold, and then allowing it to cool. Certain metal elements are added to the aluminum alloys to ensure precise casting and enhance flow properties. However, it's important to note that adding these elements, such as silicon, makes the resulting alloys unsuitable for anodizing.

Commonly utilized die-cast aluminum alloys, like Aluminum 360, Aluminum 383 (ADC12), Aluminum A356, Aluminum A380, and Aluminum B390, are chosen for their casting suitability. These alloys exhibit favorable characteristics for the precision casting process, but the presence of alloying elements makes them unsuitable for anodization.

On the other hand, anodized aluminum alloy is tailored explicitly for parts requiring surface anodization. This specialized aluminum alloy is carefully formulated to achieve various colors through the anodization process while forming a protective film of Al2O3. This protective film enhances the aesthetic appeal by allowing color customization and protecting against corrosion and wear.

Significance Of Developing Cast Aluminum Suitable For Anodizing

Developing cast aluminum alloys tailored for anodizing is essential in precision casting and custom part manufacturing. This strategic focus on creating alloys suitable for anodization aligns with the growing demand for enhanced surface treatments and aesthetic customization. Here are vital aspects that Neway highlights the significance of this development:

Surface Aesthetics and Customization:

Anodizing allows for a spectrum of colors and finishes on aluminum surfaces, contributing to enhanced aesthetics.

By developing alloys optimized for anodization, Neway ensures clients have the flexibility to achieve a wide range of desired colors, textures, and appearances.

Corrosion Resistance and Durability:

Anodized aluminum surfaces form a protective oxide layer that enhances corrosion resistance.

Tailoring cast aluminum alloys for anodizing ensures visual appeal and improved durability and longevity of the components, especially in challenging environments.

Diverse Applications:

Anodized aluminum parts find applications in various industries, including automotive, aerospace, electronics, and consumer goods.

Developing cast aluminum alloys suitable for anodizing broadens the scope of Neway's clientele by catering to diverse industries with varying requirements for both functionality and appearance.

Client Satisfaction and Differentiation:

Meeting the demand for anodized aluminum alloys demonstrates Neway's commitment to providing comprehensive solutions to clients.

This specialization serves as a unique selling point, differentiating Neway from competitors and establishing the company as a leader in precision casting with a focus on surface treatment capabilities.

Optimized Anodizing Process:

Alloys tailored for anodization streamline the anodizing process, ensuring better oxide layer adherence and consistency.

This optimization contributes to efficiency in manufacturing, reducing potential rework and enhancing overall production reliability.

Adaptability to Market Trends:

With increasing emphasis on customized and visually appealing products, the ability to offer anodized aluminum alloys positions Neway to adapt to evolving market trends and consumer preferences.

In summary, the significance of developing cast aluminum alloys suitable for anodizing lies in meeting the rising demand for visually appealing, corrosion-resistant components across diverse industries. This strategic focus enhances Neway's competitive edge, positioning the company as a versatile and forward-thinking player in the precision casting industry.

Understanding Anodizing

Aluminum anodizing is an electrochemical process that enhances the surface properties of aluminum, creating a protective and decorative oxide layer. This process involves immersing the aluminum in an electrolytic solution and applying an electric current. Here's a concise overview of the aluminum anodizing process:

Anodizing Steps:

Cleaning:

The aluminum part undergoes thorough cleaning to remove dirt, grease, or other contaminants from its surface. This step ensures proper adhesion of the anodized layer.

Preparation:

The cleaned aluminum part is then prepared for the anodizing process. It may involve masking certain areas if selective anodizing or specific surface treatments are required.

Degreasing:

The aluminum is immersed in a degreasing solution to eliminate any remaining oils or residual contaminants.

Etching (Optional):

In some cases, an etching step may be included to create a micro-rough surface on the aluminum, promoting better adhesion of the anodized layer.

Anodizing Bath:

The prepared aluminum part is immersed in an electrolytic bath containing an acidic solution, often sulfuric acid. The aluminum serves as the anode in this electrochemical process.

Anodization:

An electric current is applied to initiate the anodization process. Oxygen ions are released at the aluminum surface, leading to the controlled formation of aluminum oxide (Al2O3) on the part's surface.

Coloring (Optional):

If desired, the anodized aluminum part may undergo a coloring step. It involves immersing the part in a dye solution or using an electrolytic process to achieve various colors on the oxide layer.

Sealing:

The part is sealed to enhance the durability of the anodized layer. Sealing involves closing the pores in the anodized layer through methods such as hot water, steam, or chemical sealing.

Rinsing:

The anodized and sealed aluminum part is thoroughly rinsed to remove residual chemicals from the surface.

Drying:

The final anodized aluminum part is dried to ensure it is moisture-free before further processing or use.

These steps collectively result in an anodized aluminum part with improved corrosion resistance, durability, and, if applicable, customized color options. This process is crucial for Neway's production engineers to master, as it enhances the quality and versatility of their custom metal components, meeting their clients' functional and aesthetic requirements.

Critical Benefits of Aluminum Anodizing:

Enhanced Corrosion Resistance:

Anodizing forms a protective oxide layer on the aluminum surface, significantly improving its resistance to corrosion and environmental degradation.

Increased Durability:

The anodized layer is more complex than untreated aluminum, providing enhanced durability and wear resistance, which are crucial for components in demanding applications.

Aesthetic Customization:

Anodizing allows for various colors and finishes, providing aesthetic customization options for decorative or branding purposes.

Improved Surface Hardness:

The anodized layer increases the surface hardness of aluminum, contributing to improved scratch and abrasion resistance.

Electrical Insulation:

The anodized layer is an electrical insulator, making anodized aluminum suitable for applications where electrical conductivity needs to be minimized.

Thermal Insulation:

Anodized aluminum exhibits improved thermal insulation properties, making it suitable for applications with essential temperature resistance.

Environmentally Friendly:

Anodizing is an environmentally friendly process that does not involve heavy metals or produce harmful by-products. It creates a stable and non-toxic surface.

Dimensional Stability:

Anodizing minimally affects the dimensions of the aluminum part, ensuring that tight tolerances and precise dimensions are maintained.

Non-Reflective Surface:

Anodized surfaces can be engineered non-reflective, making them suitable for applications where glare reduction is essential, such as optical instruments.

Adhesion for Adhesives and Paints:

The porous nature of the anodized layer enhances the adhesion of adhesives and paints, allowing for additional customization and coating options.

Easy Maintenance:

Anodized surfaces are easy to clean and maintain, contributing to the longevity of the treated aluminum components.

Cost-Effective:

Considering the extended lifespan and reduced maintenance requirements, anodizing is a cost-effective solution for improving the performance of aluminum parts over time.

Why Ordinary Die-cast Aluminum alloys Are Not Suitable For Anodizing

Ordinary die-cast aluminum alloys, commonly used in precision casting processes like die casting, sand casting, and gravity casting, are not suitable for anodizing due to the presence of alloying elements, mainly silicon. These alloys, such as Aluminum 360, Aluminum 383 (ADC12), Aluminum A356, Aluminum A380, and Aluminum B390, are chosen for their casting properties, which facilitate the molding and formation of intricate parts.

The addition of alloying elements like silicon enhances the flow properties of the molten aluminum during the casting process, allowing for the creation of complex shapes and detailed components. However, this comes at a cost when considering anodization.

During the anodizing process, aluminum undergoes electrolytic oxidation to form a protective oxide layer on its surface. This layer is crucial for enhancing corrosion resistance and providing a base for coloring or other finishes. However, alloying elements, especially silicon, interfere with forming a consistent and high-quality oxide layer.

The result is an anodized surface that may be uneven, porous, or exhibit undesirable visual characteristics. Therefore, it's essential to use aluminum alloys tailored explicitly to achieve the desired aesthetic and functional benefits of anodization. These specialized alloys are carefully formulated to ensure an even and durable anodized finish while maintaining other desired material properties.

For Neway, this distinction underscores the importance of selecting suitable materials based on the intended application and surface treatment requirements. It reflects a commitment to precision and expertise in delivering customized solutions that meet the unique needs of their clients.

Application Scenarios Of Anodized Aluminum Die Castings

Anodized aluminum die castings find application across various industries due to their enhanced properties and aesthetic appeal. As a custom parts manufacturer, Neway can showcase the versatility of anodized aluminum die castings in several application scenarios, highlighting their unique benefits. Here are some notable examples:

Automotive Components:

Anodized aluminum die castings are widely used in the automotive industry for components like decorative trims, grilles, and interior detailing.

The anodized surface provides an attractive finish and enhances corrosion resistance, which is crucial for automotive parts exposed to diverse environmental conditions.

Electronics Housings:

Electronic devices often utilize anodized aluminum die castings for casings and enclosures.

The anodized finish offers a sleek appearance and a durable protective layer, ensuring longevity and reliability in electronic applications.

Medical Equipment:

The corrosion-resistant nature of the anodized surface is beneficial in medical environments where cleanliness and durability are paramount.

Aerospace Components:

In the aerospace industry, where lightweight and durable materials are crucial, anodized aluminum die castings are employed for various components, including housings and brackets.

The corrosion-resistant properties of the anodized surface contribute to the longevity and reliability of aerospace parts.

Consumer Goods:

Anodized aluminum die castings are popular in producing consumer goods such as appliances, furniture, and sporting equipment.

Achieving different colors through anodization allows for customization, meeting consumers' aesthetic preferences.

Architectural Applications:

Anodized aluminum die castings are vital in architectural elements such as decorative panels, window frames, and door hardware.

The anodized finish adds visual appeal and ensures resistance to weathering and corrosion in outdoor applications.

Lighting Fixtures:

The lighting industry often utilizes anodized aluminum die castings for components like lamp housings and decorative fixtures.

The anodized surface provides a durable and aesthetically pleasing finish crucial for lighting applications.

By showcasing these application scenarios, Neway can effectively communicate the broad range of industries that benefit from anodized aluminum die castings—emphasizing the dual advantages of enhanced functionality and aesthetic appeal, positioning Neway as a reliable provider of customized solutions for diverse client needs.

When To Choose Anodizing Cast Aluminum?

Choosing to anodize cast aluminum is a strategic decision that depends on the application's requirements and the final product's desired properties. Here are scenarios when it is advantageous to choose anodizing for cast aluminum:

Enhanced Corrosion Resistance is Essential:

Anodizing creates a protective oxide layer on the aluminum surface, significantly improving corrosion resistance. Choose anodizing when the cast aluminum parts will be exposed to corrosive environments, such as outdoor applications or industrial settings.

Aesthetic Customization is Desired:

Anodizing provides a customizable solution if the application requires a specific color or aesthetic finish. Different colors can be achieved through anodization, making it suitable for decorative elements or products with branding considerations.

Improved Hardness and Wear Resistance Needed:

Anodized aluminum surfaces are more complex than untreated aluminum, offering increased wear resistance. Choose anodizing for cast aluminum components in applications where durability and resistance to abrasion are crucial.

Electrical Insulation is a Requirement:

Anodized aluminum serves as an electrical insulator. Anodizing is a suitable choice if electrical conductivity needs to be minimized, such as in electronic components or specific assemblies.

Thermal Insulation is Important:

Anodized aluminum exhibits improved thermal insulation properties. Anodizing can provide thermal resistance if the cast aluminum parts are subjected to temperature variations.

Non-Reflective Surface is Preferred:

Anodized surfaces can be engineered non-reflective in applications where glare reduction is essential, such as optical instruments or displays.

Customization for Branding or Product Differentiation:

Anodizing allows for branding through color customization. Choose anodizing when the aesthetic appearance of the cast aluminum parts plays a role in product branding or differentiation.

Minimized Maintenance and Long-Term Durability:

Anodized surfaces are easy to clean and maintain. Choose anodizing when long-term durability and reduced maintenance requirements are priorities for the application.

Adhesion for Additional Coatings is Required:

The porous nature of the anodized layer enhances adhesion for paints, adhesives, or other coatings. Choose anodizing when additional coatings are part of the manufacturing process.

Cost-Effective Long-Term Solution:

Considering the extended lifespan and reduced maintenance associated with anodized aluminum, choosing anodizing can be cost-effective over the long term.

By considering these factors, you can make informed decisions on when to choose anodizing for cast aluminum, ensuring that the selected surface treatment aligns with the specific needs and goals of the custom part manufacturing process.

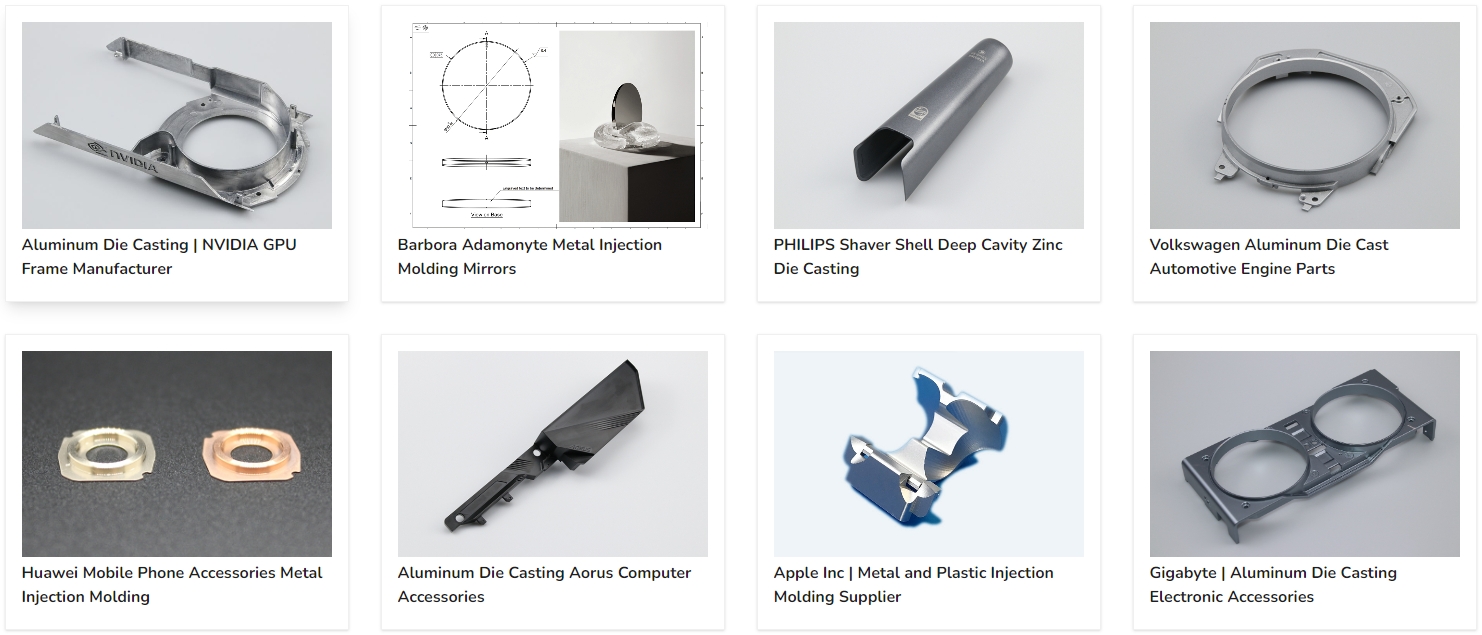

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.

Neway Custom Manufacturing Capability

Neway has gradually improved the production system of basic hardware, plastic, and ceramic non-standard parts after 30 years of growth from the original CNC workshop. As well as polishing, PVD, and simple assembly lines. Provide one-stop, non-standard manufacturing services to our customers.

评论

发表评论