Zirconia (ZrO2) Ceramic Injection Molding (CIM) service

ZrO2 ceramic injection molding (CIM) process is a manufacturing process that uses ceramic powders to create complex, high-precision parts. The process starts with mixing the ceramic powder with binders and then injecting the mixture into a mold. The mold is then heated to a high temperature, melts the binders, and sinters the ceramic powder together.

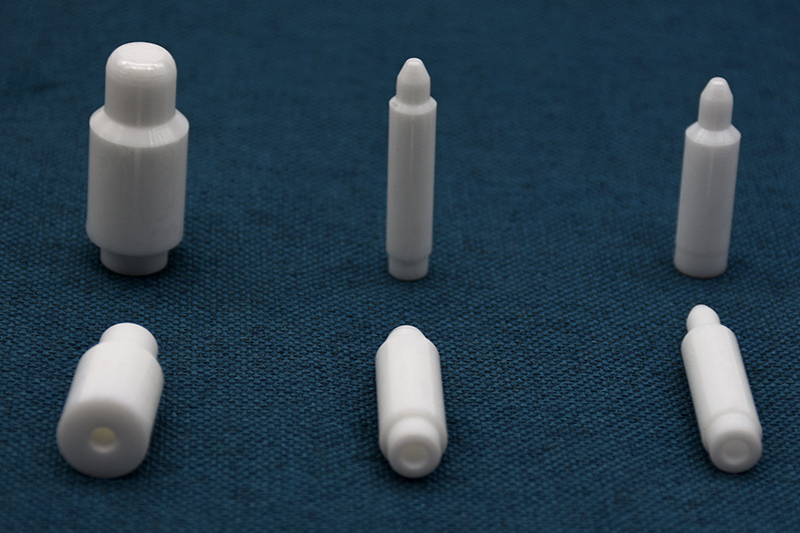

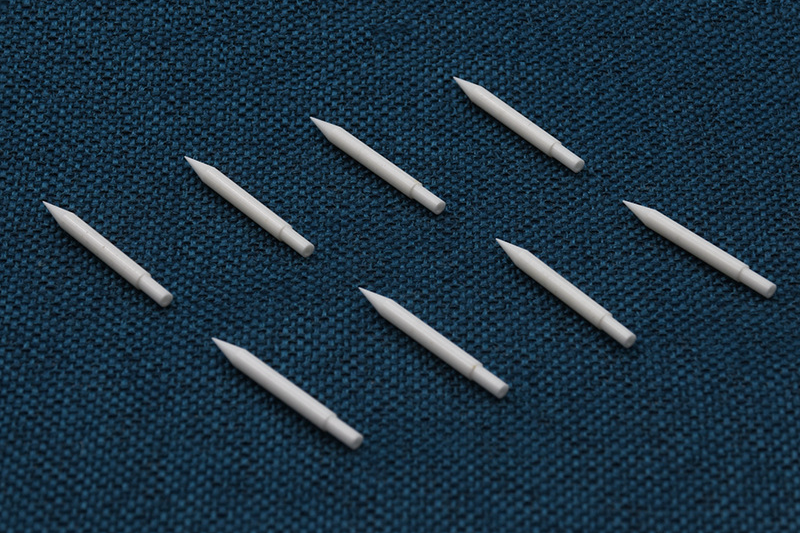

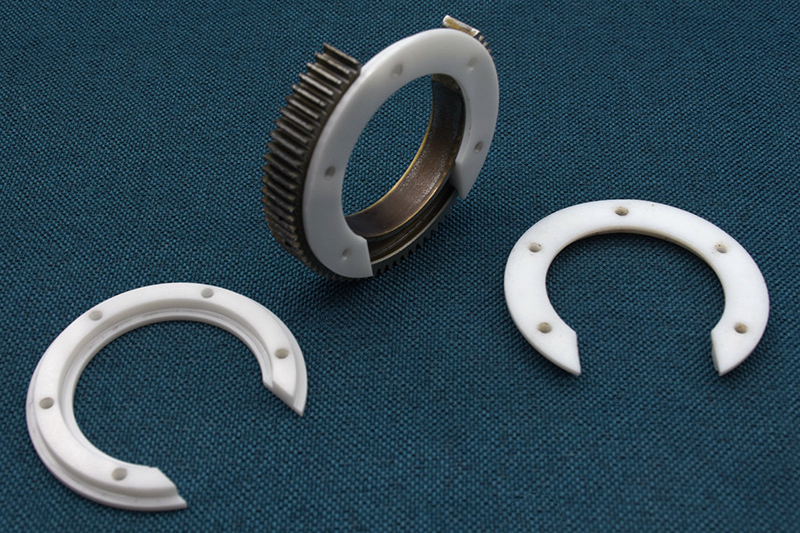

ZrO2 CIM parts have exceptional mechanical strength, high fracture toughness, and superb corrosion resistance. Zirconia CIM parts shine as dental implants, prosthetics, and joint replacements in the medical realm thanks to their biocompatibility and durability.

Beyond healthcare, CIM ZrO2 is the choice for industrial components exposed to corrosive environments, such as valves, pump parts, and even specialized tools. Our Zirconia CIM service embodies the future of precision engineering, catering to the most demanding industries and pushing the boundaries of ceramic innovation.

CIM Zirconia (ZrO2) Typical Properties

Download PDF: CIM-Zirconia (ZrO2) Datasheet |

|---|

Physics and Mechanical Properties

Properties | Fracture Toughness (MPa√m) | Flexural Strength (MPa) | Impact Strength (J/m) | Hardness (HRA) | Young's Modulus (GPa) | Elastic Modulus (GPa) | Thermal Expansion (10^-6/°C) | Compressive Strength (MPa) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

CIM Zirconia (ZrO2) | 10.0 | 1000 | 8.0 | 85 | 200 | 220 | 10.5 | 2000 | 6.0 |

Key Features And Applications of CIM-ZrO2 Parts

Fracture Toughness

The fracture toughness of CIM-ZrO2 parts is achieved through a combination of factors, including the material's composition, microstructure, and manufacturing process. The yttria content is one of the most critical factors affecting fracture toughness. Yttria-stabilized zirconia (YSZ) is a type of zirconia that has been stabilized with yttria, which increases its fracture toughness. The microstructure of the material also plays a role. A fine-grained microstructure is generally associated with higher fracture toughness. Finally, the manufacturing process can also affect fracture toughness. CIM-ZrO2 parts are typically manufactured using injection molding, which helps ensure a fine-grained microstructure.

Fracture toughness measures a material's ability to resist crack propagation. It is critical for many applications, such as medical implants and aerospace components. CIM-ZrO2 parts have a fracture toughness of 10-12 MPa m^1/2, higher than many other materials. It makes them well-suited for applications exposed to high stress or impact loads.

Flexural Strength

Ceramic Injection Molding (CIM) Zirconia (ZrO2) parts demonstrate an impressive flexural strength of 1000 MPa. This characteristic showcases the material's resistance to bending and deformation under applied loads. CIM-ZrO2's remarkable flexural strength is attributed to its microstructure, which provides structural integrity and stability, making it an ideal choice for applications that demand load-bearing capacity and mechanical durability.

Zirconia (ZrO2) CIM parts find crucial applications in industries where flexural strength is paramount. In aerospace and defense, CIM-ZrO2 components excel as structural elements due to their ability to withstand mechanical stresses and variations in temperature. In industrial machinery, CIM-ZrO2 parts contribute to valves, seals, and bearings, where their flexural strength ensures reliability in heavy-duty operations.

Impact Strength

Ceramic Injection Molding (CIM) Zirconia (ZrO2) parts exhibit an impact strength of 10-20 kJ/m^2, showcasing their ability to absorb energy from sudden impacts without fracturing. This characteristic is essential for applications where components may experience sudden shocks or forces. CIM-ZrO2's notable impact strength stems from its tough microstructure, enabling it to withstand and dissipate energy effectively.

Zirconia (ZrO2) CIM parts find applications in industries that require robust impact strength properties. In automotive engineering, CIM-ZrO2 components contribute to safety systems, such as airbag deployment mechanisms, where impact resistance is crucial. Additionally, CIM-ZrO2 is used in machinery subjected to vibrations and mechanical shocks, ensuring that components retain their structural integrity and performance over time.

Hardness

Ceramic Injection Molding (CIM) Zirconia (ZrO2) parts demonstrate a hardness of 85 HRA, highlighting their exceptional resistance to wear and abrasion. The high hardness level ensures prolonged service life and minimized material degradation. It makes them well-suited for applications exposed to wear and abrasion, such as in bearings and seals.

Zirconia (ZrO2) CIM parts find vital applications in industries that demand superior hardness properties. CIM-ZrO2 components are used for cutting tools and wear-resistant parts in manufacturing and machining, where hardness is essential to maintain sharpness and integrity in high-speed machining processes. CIM-ZrO2's hardness is also crucial for applications in harsh environments such as mining and material processing, where components encounter challenging and abrasive materials.

Load Capacity

The load capacity of Ceramic Injection Molding (CIM) Zirconia (ZrO2) parts is primarily determined by their flexural strength and fracture toughness, which are 1000 MPa and 10.0 MPa√m, respectively. These properties indicate CIM-ZrO2's ability to withstand applied loads and resist fracture, making it suitable for applications that require high load-bearing capacity. The combination of strength and toughness ensures that CIM-ZrO2 parts can endure mechanical stress and carry substantial loads without compromising structural integrity.

Zirconia (ZrO2) CIM parts find critical applications in industries where load capacity is a pivotal consideration. In aerospace engineering, CIM-ZrO2 components contribute to structural elements of aircraft and spacecraft, where their load-bearing capability ensures safety and stability. CIM-ZrO2 parts are integral components of heavy machinery subjected to substantial mechanical loads in manufacturing and industrial machinery, enhancing overall equipment reliability and performance.

Consultative Design Services

Neway Custom Metal Injection Molding Service provides free Consultative Design Services throughout the process. This includes all processes from your design stage to mass-produced finished products.

1. Material selection Consult

2. Structural design service

3. Mold design service

Contact us now if you are interested.

What We Can Offer?

We offer free material selection and consultative design services from beginning to end. No MOQs, Rapid prototyping, and mass production are our strengths.

评论

发表评论