Sintered Gears Bushings Overview

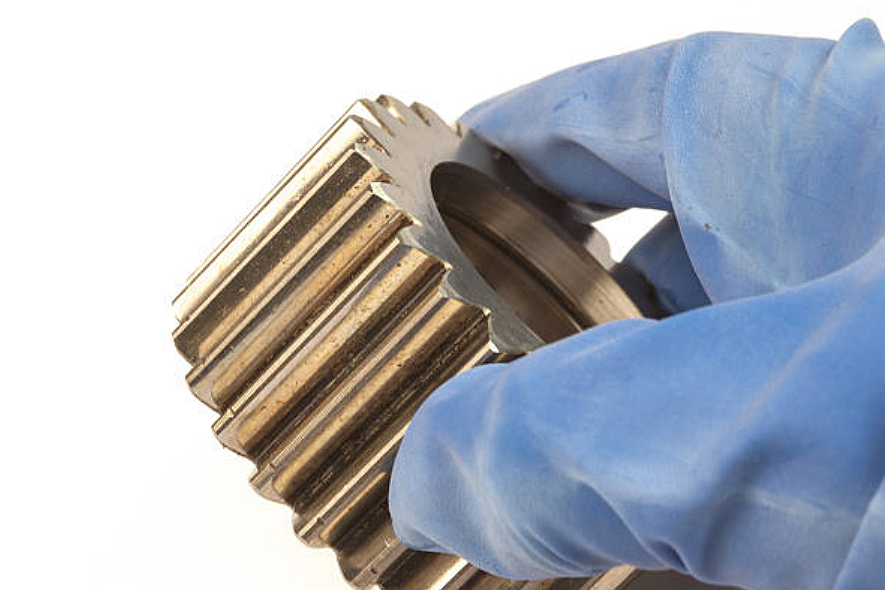

Sintered self-lubricating gears, bushings, and bearings refer to powder metallurgy components with porosity and impregnated lubricants to provide continuous lubrication during operation without needing external lubricant replenishment. Compared with solid gears, bushings, and bearings, they are lightweight, porous, self-lubricating, and high-strength. We usually use two kinds of powder metal manufacturing methods to produce sintered gears and self-lubricating bushings, namely metal injection molding and powder compression molding, which belong to the powder metallurgy process.

Solid metal gear, bushings manufacturing methods

The primary manufacturing processes for solid metal gears and bushings each offer distinct advantages. Gear machining allows high-precision profiling and finishing, but casting provides near-net shape capability. Forging improves strength through grain flow shaping. Bushing machining enables tight tolerances and surface finish quality, while broaching facilitates complex internal features. Cast bushings can be produced rapidly in complex shapes needing minimal finishing.

CNC Machining - Gear cutting processes like hobbing, shaping, and milling allow gears to be precision machined from metal blanks. Most common method.

Casting - Metal casting can be used to produce crude gear blanks that require additional machining. Saves material versus machining blanks.

Forging - Gear blanks can be forged from metal stock to basic shapes before machining. Provides grain flow strengthening.

Extrusion - Hot extrusion of certain metals can produce seamless bushings to a close tolerance.

Improved Wear Resistance

Powder molded gears and bushings leverage capabilities like impregnated lubrication, fine carbides, and custom alloys to significantly improve wear properties and part life compared to traditional fabrication methods.

- Lubricant Impregnation - The porosity in sintered parts allows lubricants like oil and graphite to be retained. This provides continuous lubrication to the contact surfaces, minimizing wear.

- Finer Carbides - The rapid cooling inherent in powder sintering results in very fine and uniformly dispersed carbides in the microstructure. This enhances wear resistance.

- Work Hardening - The compressive forces during compaction work harden the material. This further improves abrasion resistance.

- Material Flexibility - A more comprehensive range of alloys tailored for wear resistance can be used in sintering than wrought alloys. Elements like chromium, nickel, and molybdenum can be added.

- Composition Control - Powder metallurgy allows precise composition control versus variability in cast alloys. This optimizes properties.

- Density Gradient - Some porosity can be maintained near the surface to hold lubrication while the core remains fully dense for strength. It reduces surface wear.

Noise Dampening

Powder-compressed gears and bushings leverage unique attributes like porosity, material gradients, and molded shapes unavailable in solid metals to provide unparalleled acoustic dampening and quiet operation.

- Porous Structure - The inherent porosity and voids in sintered parts absorb and dissipate vibration energy and sound waves, reducing noise.

- Interparticle Friction - Friction between the metal powder particles and at particle boundaries also dampens vibration transmission through the sintered structure.

- Improved Fit - The porosity allows improved fit between mating components. It minimizes vibration generation from gaps or poor fit.

- Lubrication Effect - Lubricants impregnated in the pores minimize metal-to-metal contact, a noise source. The lubricant films dampen vibrations.

- Reduced Rigidity - Some reduction in modulus of elasticity with sintering relative to solid metals contributes to vibration damping.

- Improved Damping Capacity - Powder metallurgy allows tailored compositions and properties to enhance damping capacity.

- Shape Optimization - Sintering enables molded shapes, surface patterns, or fins to optimize damping through geometric effects.

Complex Geometries

The combination of near-net shape molding, automated processing, and composition flexibility provided by powder metallurgy imparts exceptional geometric capabilities for molded gear and bushing design.

- Near Net Shape - Sintered parts are formed by molding metal powder very close to the desired shape and dimensions. It minimizes the need for the machining of complex forms.

- Design Flexibility - Molds allow tremendous freedom in designing intricate, nonuniform internal and external geometries that cannot be produced by machining.

- Consolidation of Parts - Complex assemblies can be simplified by consolidating components into a single sintered part with embedded features.

- No Draft Requirements - Vertical walls, undercuts, and negative draft features are possible since powder molding does not require draft angles needed in casting.

- Customized Density - Sections of different densities can be built into a single part by varying compaction in specific regions. It allows further shape optimization.

- Post-Processing - Secondary operations like coining, forging, or rolling after sintering can enhance detailed shapes.

- Automation - Automated molding and processing of the powder materials enables high-volume production of repeatable complex geometries.

Reduced Friction

The combination of composition choices, net shape accuracy, and lubricant retention provided by powder molding gives molded gear and bushing components unparalleled low-friction capabilities.

- Impregnated Lubricants - The porosity enables lubricants like oil or graphite to be retained in the material, providing continuous lubrication at the contact surfaces and reducing friction.

- Finer Surface Finish - Sintering can produce smooth surface finishes, reducing friction due to lower asperity contact. Post-sintering operations enhance the finish further.

- Dimensional Control - The net shape capability of sintering results in precise dimensional control, enabling better clearance fits and lower eccentricity, which reduces friction.

- Composition Flexibility - Adding alloying elements like carbon, copper, and tin optimizes material properties like thermal conductivity, damping, and contact surface chemistry to minimize friction.

- Density Gradient - Higher porosity and lower density at the surface retain more lubricant at the critical interface leading to less friction.

- Graphite Lubrication - The layered structure of impregnated graphite enables it to sheer easily at the contact zones, providing low friction lubrication.

- Lower Elastic Modulus - Some reduction in modulus relative to fully dense alloys lowers surface stresses and friction.

Lightweighting Potential

Powder molded gears and bushings leverage low-density compositions, optimized geometries, and integrated assemblies unavailable in wrought metals to enable unprecedented lightweight capabilities.

- Porosity - The controlled porosity intrinsically built into the sintered structure reduces mass and density, providing an inherent weight reduction.

- Lower Density Materials - Elemental powders of lower density, like titanium or aluminum, can be used in sintering to manufacture lightweight components.

- Thinner Sections - The high specific strength of sintered parts allows designs with thinner sections and walls while maintaining strength. It reduces weight.

- Material Reduction - Porous surface layers on sintered parts retain lubricants, allowing the use of less material for the same performance.

- Part Consolidation - Complex assemblies can be consolidated into single sintered parts, eliminating separate fasteners and joints that add weight.

- Topology Optimization - Organic shapes and voided structures tailored for loading conditions can be molded to put strength only where needed.

- Dimensional Precision - Consistent tolerance control allows very thin, precise wall thicknesses and cross-sections impossible by other methods.

- Strength-to-Weight Ratio - Fine dispersed carbides and work hardening effects give sintered parts good specific strength for their weight.

Sintered Self-lubricating Bronze Bearings

Sintered bronze bearings provide optimal performance properties, making them superior to many other bearing materials. The porous structure enables lubricant impregnation for self-lubrication and friction reduction without frequent reapplication. It also dampens noise and vibration. At the same time, the bronze composition offers high load capacity and good wear resistance while maintaining dimensional stability across operating temperatures. Sintered bronze can be tailored to enhance specific properties like maximizing wear performance with unique alloying additions. The bearings have good machinability for additional fabrication. Overall, sintered bronze's self-lubrication, strength, stability, and customizability make it an excellent, cost-effective bearing solution for demanding mechanical applications. The powder metallurgy production method allows high-quality bearings to be manufactured to net shape with tight tolerances in an efficient and affordable process.

These properties allow sintered bronze bearings to be utilized in various demanding mechanical and tribological applications across industries. Typical uses include automotive bushings and bearings, materials handling systems like conveyors or robotics, high-pressure fluid pumping systems, precision instruments, valves, electrical motors and switchgear, construction/mining machinery, and more. The self-lubrication capability, high load capacity, temperature stability, and cost-efficient manufacturing give sintered bronze bearings versatility across performance-critical bearing applications. The powder metallurgy production method allows high-quality bronze bearings to be manufactured to net shape while avoiding costly machining procedures.

When Use Powder Compression Molding

For gear and bushing applications where complexity, productivity, and performance are essential, powder molding provides unmatched advantages over traditional subtractive manufacturing methods.

- Design Complexity - Sintering enables intricate, nonuniform internal and external geometries difficult or impossible to produce by machining or other methods.

- Productivity - Automated compaction and sintering allow high-volume net shape production at lower costs than subtractive fabrication.

- Self-Lubrication - Impregnation of lubricants into the porous structure gives sintered components inherent self-lubricating properties not achievable with solid metals.

- Property Combinations - Unique and tailored properties like density gradients, controlled porosity, and alloying additions can be designed into sintered parts.

- Part Consolidation - Complex assemblies with multiple components can be easily consolidated into single sintered parts.

- Non-Ferrous Materials - Sintering allows non-ferrous metals like bronze, copper, and titanium alloys, typically not used for machined gears/bushings.

- Performance Enhancement - Fine microstructures and isotropic properties from powder processing enhance strength, toughness, and functionality.

- Near-Net Shape Parts - Sintering produces components close to final dimensions, minimizing machining and associated costs.

Overall, for gear and bushing applications requiring unique geometries, properties, or scale production, the design and manufacturing flexibility offered by powder sintering provides significant advantages over subtractive methods and conventional fabrication.

Why Choose Neway?

Neway, a trusted industry leader for 30 years, is excited to announce an unbeatable offer for new customers. In 2023, you can experience Neway's exceptional services with an enticing 20% discount on your first order. Neway guarantees the highest quality and precision in every project as a manufacturer specializing in metal, ceramic, and plastic injection molding, precision casting, sheet metal processing, and rapid prototyping. Neway's advanced manufacturing techniques deliver unparalleled durability and performance, whether you require sintered gears or self-lubricating bushings. With Neway by your side, you can unlock the potential for success in your endeavors. Take advantage of this exclusive opportunity to embrace success and discover why Neway is the preferred choice for countless satisfied customers.

评论

发表评论