Definition of Gas-Assisted Injection Molding

Gas-assisted injection molding is a manufacturing process that uses inert gas to apply internal pressure inside a molten plastic part during the plastic injection molding process. This results in hollow, lightweight parts with thick walls and uniform thickness.

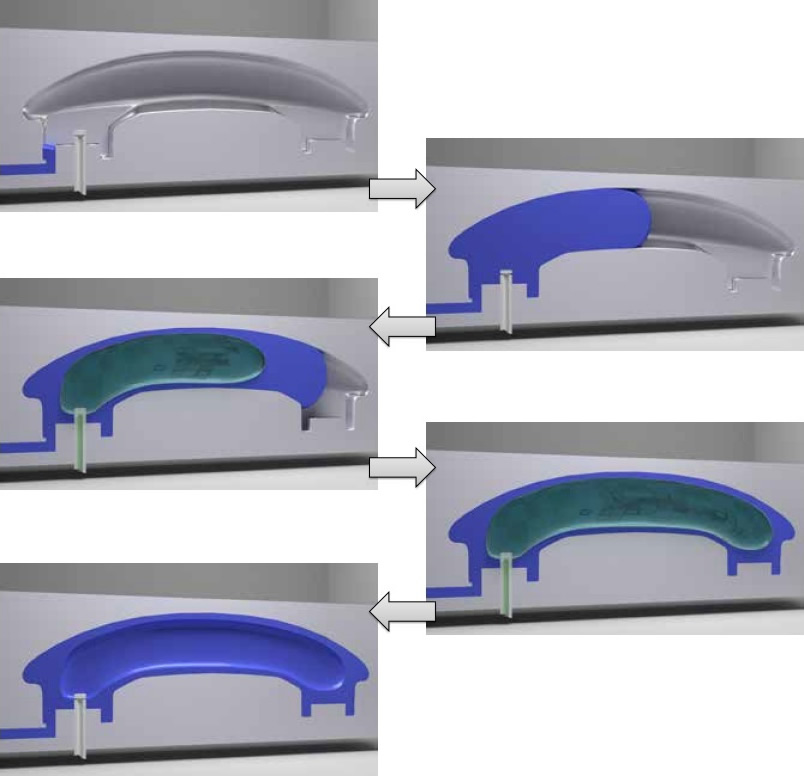

Gas-assisted injection molding includes four basic steps:

Molten plastic is injected into a mold cavity under high pressure, filling most but not all of the cavity.

Once the plastic has partially solidified, an inert gas such as nitrogen is injected into the still-molten core of the part. This gas gets injected through the injection nozzle into the mold's hollow section called the gas channel.

The gas applies outward pressure from inside the part, pushing the plastic against the walls of the mold cavity. It helps pack out the part and eliminate sink marks.

The part continues cooling, with the gas pressure holding the plastic against the mold walls. The result is a robust, lightweight part with hollow internal ribs or sections.

Benefits of Gas-Assisted Injection Molding

The advantages of gas-assisted injection molding make it a popular choice for automotive, consumer, industrial, and medical applications requiring large, robust plastic parts. The process reduces production costs while improving part quality compared to conventional injection molding.

Reduced weight: The hollow interior sections create a lighter part, reducing material use and costs. It is helpful for parts like automotive components where weight reduction is essential.

Thicker walls: The gas pressure packs out the plastic, allowing thicker, more uniform wall thicknesses. It improves strength.

Faster cycles: The gas rapidly cools the hot plastic from the inside out, reducing cooling time. It allows faster production cycles.

More significant parts: The gas pressure allows molding of larger, more complex parts by thoroughly packing out the plastic.

Less stress: The rapid cooling and gas packing produces less internal stresses in the part.

Reduced warp: The uniform cooling and wall thicknesses minimize warp and shrinkage.

Fewer sink marks: The gas pressure prevents sink marks that can occur with regular injection molding.

Conventional Injection Molding

Conventional Injection Molding involves injecting molten plastic into a mold cavity under high pressure. The plastic fills the entirety of the cavity and is held under pressure as it cools and solidifies.

Plastic pellets are fed into an injection molding machine, melting into liquid.

The molten plastic is injected through a nozzle into the mold cavity under high pressure, filling the entire cavity.

Pressure is maintained on the plastic to pack it into the cavity as it cools and solidifies.

The mold opens once the plastic has hardened enough and the part is ejected.

The mold closes, and the cycle repeats for the next part.

The cooled plastic in the mold shrinks slightly, which can lead to sink marks on the part's surface. Controlling shrinkage and achieving uniform wall thicknesses can be difficult with conventional injection molding, especially for large parts.

The process is relatively fast and economical for small to medium-sized plastic parts in high volumes. However, warpage and sink marks become issues for larger, thicker-walled parts molded with conventional injection.

Limitations and Challenges

Conventional injection molding is best suited for small to medium-sized plastic parts. More significant parts tend to warp, have sink issues, require longer cycles, and need prohibitively expensive equipment. Here are some fundamental limitations and challenges with conventional injection molding:

Thin walls: It can be challenging to fill thick cross-sections as the plastic may solidify before the mold cavity is packed out, leading to voids and weak spots.

Sink marks: Shrinkage, as the plastic cools, causes depressions or sink marks in visible surfaces.

Warpage: Non-uniform cooling and fill can cause parts to warp or distort after ejection.

Weight: Solid plastic parts are heavier than hollow parts.

Stresses: Cooling and shrinkage introduce internal stresses in the part.

Large parts: Size is limited since cooling time increases with part thickness. Larger molds also require higher clamping forces.

Complex geometries: Intricate shapes with ridges and bosses can be problematic to fill.

Appearance: Sink marks and warp lower the surface quality and appearance.

Nozzles: The injection nozzle must align with the parting line, limiting options for where to inject plastic.

Equipment size: Machines are more extensive and more expensive for large-part molding.

How Gas-Assisted Injection Molding Works

The gas allows molding of more significant, thicker-walled parts by reducing cooling time and ensuring proper packing. It improves the surface finish, dimensional accuracy, and physical properties compared to conventional injection molding.

Careful control of process parameters like gas pressure, timing, and flow is crucial to create an optimal internal structure and quality parts. Gas-assist injection molding produces lightweight, high-quality plastic parts quickly and cost-effectively. Here is an explanation of how gas-assisted injection molding works:

Molten plastic is injected into the mold cavity under high pressure, filling 60-90% of the part volume.

Once the plastic partially solidifies into a skin, an inert gas (typically nitrogen) gets injected into the still-molten plastic core through the injection nozzle.

The gas follows specially designed channels in the mold to penetrate the length of the part.

The gas exerts outward pressure on the interior, pushing the pliable plastic against the mold surfaces.

It fills corners, packs out walls, and eliminates sinks and voids as the plastic continues cooling.

The result is a lightweight, hollow part with high rigidity and thick uniform walls.

The mold opens after the plastic fully solidifies and the part is ejected. Residual gas escapes through vents.

Advantages

Gas-Assisted Injection Molding provides lighter, faster, and higher quality production of large, complex injection molded parts compared to standard injection molding.

Lower weight: The hollow interior sections reduce part weight, using less material.

Thicker walls: The gas pressure allows packing out of thicker wall sections. It improves strength and rigidity.

Faster cycles: The gas rapidly cools the part from the inside, reducing molding cycle times.

Dimensional accuracy: The gas provides uniform pressure, reducing warpage and improving precision.

More extensive parts: The gas allows complete filling and cooling of more extensive, thicker parts.

Complex shapes: Intricate geometries and deep ribs are packed out.

No sink marks: The gas prevents sink marks on visible surfaces.

Less flash: The lower clamping pressure prevents flash around mold cavities.

Lower tooling cost: Simple tool design without many vents or side cores.

Potential Defects

Short shots: Incomplete mold filling due to low injection pressure or early gas injection.

Voids/porosity: Gases trapped within the plastic due to improper venting.

Sinks and cracks: Uneven filling and gas penetration cause sinks and cracks.

Warpage: Improper packing, non-uniform wall thickness, or cooling causes warpage.

Flash: Gas leakage causes excess plastic to be forced into mold parting lines.

Dimensional variations: Improper process settings lead to thickness/tolerance issues.

Quality Control

Monitoring of process parameters: Precisely control injection pressure, time, temperature, and gas pressure.

Proper venting: Ensure vent locations and sizes allow all trapped gases to escape.

Mold maintenance: Keep mold surfaces clean and at proper temperatures.

Balanced cooling: Uniform cooling of mold surfaces to prevent warpage.

Dimensional inspection: Verify critical dimensions to catch any process deviations.

Visual inspection: Check for surface defects and inconsistencies after demolding.

Destructive testing: Cut open random parts to inspect interior rib formations.

Controlling the process and performing inspections and testing helps minimize potential defects and improve overall part quality from the gas-assist process.

Design Considerations and Guidelines

Proper part design and process optimization are vital to maximizing the benefits of gas-assisted injection molding. Following design guidelines will result in high-quality, dimensionally accurate parts. Here are some key design considerations and guidelines for gas-assisted injection molding:

Wall thickness: Typical wall thicknesses range from 3mm to 6mm. Uniform thicknesses are ideal to ensure even filling.

Ribs and supports: Internal ribs and supports should be designed into the part to provide rigidity and strength. Typical rib thicknesses are 3-4mm.

Gas channels: Channels must be incorporated into the mold to direct gas flow and penetrate the complete section.

Venting: Vents need to be designed into the mold to allow trapped gases to escape after the part is packed.

Draft angles: Sufficient draft angles (>1°) should be added to inner surfaces to ease part ejection.

Geometry: Avoid overly complex geometries that may trap gases internally. Simple shapes allow for easier gas filling.

Gate location: The gate should be positioned so that gas channels easily access the total part volume.

Clamp force: Larger, thicker parts may require higher clamp forces to resist the gas pressure.

Material selection: Semi-crystalline materials like nylon work better than amorphous materials like ABS.

Gas pressure/timing: Optimal gas pressure and injection timing should be determined through mold trials.

vs. Conventional Injection Molding

Gas-assisted provides lighter, more vital, more significant parts but has higher initial costs. Conventional molding is more straightforward and cheaper but produces heavier, weaker parts. Here is a comparison of gas-assisted injection molding vs. conventional injection molding:

Part weight: Gas-assisted parts are lighter due to hollow interior vs. solid plastic in conventional molding.

Wall thickness: Gas-assisted can produce thicker, more uniform wall thicknesses and improved strength. Conventional can suffer from thin spots.

Part size: Gas-assisted enables larger part sizes, up to 200% bigger by volume. Conventional molding has size limitations.

Cooling time: Gas-assisted cooling is faster due to the interior gas expanding and cooling the plastic. Conventional molding is slower.

Cycle time: The faster cooling of gas-assisted leads to reduced cycle times. Conventional molding has longer cycles.

Clamp force: Gas-assisted requires lower clamp force since less injection pressure is needed. Conventional and needs higher clamp force.

Sink marks: Gas-assisted has minimal or no sink mark defects. Conventional parts often have visible sinks.

Warpage: Gas-assisted sees reduced warpage due to uniform cooling and packing. Conventional has higher warpage.

Part cost: Gas-assisted parts have lower per-part costs due to material savings. Conventional is higher cost.

Process cost: Gas-assisted equipment has a higher initial cost. Conventional machines are more straightforward and cheaper.

Strength: Gas-assisted typically has higher tensile and flexural strengths. Conventional properties are dependent on wall thickness.

Applications: Gas-assisted is well-suited for large, structural, load-bearing parts. Conventional for small/medium parts.

vs. Structural Foam Molding

Gas-assist provides better visual quality, dimensional accuracy, and size, while structural foam offers a maximum lightweight and lower cost for hidden parts. Here is a comparison between gas-assisted injection molding and structural foam molding:

Lightweighting: Both processes produce hollow, lightweight parts. Gas-assisted is typically lighter due to thinner walls.

Strength: Structural foam can be firmer due to foaming action expanding into the mold shape. Gas-assist strength depends on wall thickness.

Wall thickness: Gas-assisted allows thicker walls (3-6mm typical) than structural foam (<3mm).

Dimensional stability: Gas-assist offers better dimensional stability and tolerance control. The foaming process has more variability.

Cycle time: Gas-assist cycle times are generally faster due to faster cooling. Foam cooling can be slower.

Part size: Gas-assist can make more significant parts than foam molding. Foam is limited to small to medium parts.

Sink marks: Gas-assist has minimal or no sinks. Structural foam parts can show sink mark defects.

Process cost: Gas-assist has a higher equipment cost. Foam molding equipment cost is lower.

Material options: Gas-assist uses standard resins. Foam requires specialized chemical foaming agents.

Appearance: Gas-assist can produce Class A surfaces. Foam is not suitable for aesthetic appearances.

Applications: Gas-assist is used for larger, structural, and visual parts. Foam is best for simple geometries needing weight reduction.

How to Choose in Injection Molding

Key factors in choosing are: required part size, appearance, strength needs, production volumes, cost targets, and size/complexity of the mold. Gas-assist works best for large, high-quality parts needing strength. Conventional injection suits small volumes or simple geometries. Foam minimizes the weight and costs of hidden parts.

Prototyping and production trials should be used to validate the best process for an application based on the design requirements and constraints.

Here are some guidelines on when to choose gas-assisted injection molding vs. conventional injection molding vs. structural foam molding:

Gas-Assisted Injection Molding is best for:

Large, complex, thick-walled plastic parts

When strength and rigidity are important

Reducing cycle times

Minimizing sink marks and warpage

Applications where appearance is important

Conventional Injection Molding is best for:

Small to medium-sized plastic parts

Thin-walled sections

Simple geometries

Short production runs

Lower initial capital investment

Structural Foam Molding is optimal for:

Maximizing weight reduction

Simple, ribbed geometries

Hidden internal/structural parts

Lowest material usage

Lowest per-part cost

High production volumes

Why Neway for Injection Molding

"We've relied on Neway for all our injection molded parts for over a decade. Their knowledge and responsiveness consistently impress us. Components are always delivered on time and at a competitive price. I'd recommend Neway to anyone looking for an injection molding partner." - John Smith, Volkswagen Manufacturing.

评论

发表评论