Metal Injection Molding (MIM) has revolutionized the manufacturing industry by enabling the production of complex metallurgy products. One of the crucial steps in the metal injection moulding process is pressureless sintering, which enhances the density and strength of the final product. This blog post will delve into pressureless metal sintering, exploring its history, definition, operation steps, advantages, and applications. By the end, you'll understand why pressureless sintering is a game-changer in metallurgy products and why Neway is your ideal partner.

Pressureless Sintering Overview

Pressureless sintering is vital in MIM casting, transforming compacted metal powder into a solid, fully dense product. Unlike other hot pressing sintering methods, pressureless sintering does not rely on external pressure but instead relies on carefully controlled temperature profiles. This improves material properties, such as higher density, enhanced mechanical strength, and dimensional accuracy. While pressureless sintering offers several advantages, such as near-net-shape production and the ability to manufacture intricate parts, it also presents challenges, including longer cycle times and the risk of warpage. However, these drawbacks can be effectively addressed with proper expertise and advanced equipment.

Pressureless Sintering History

The history of pressureless sintering dates back to ancient times when the first attempts at creating metal objects through powdered metallurgy were made. However, in the 20th century, pressureless sintering gained significant attention. The combination of metal powders and binders in the Metal Injection Molding process further propelled the progress of pressureless sintering, producing complex and high-precision components. Today, pressureless sintering is a mature and widely adopted MIM technology in various industries.

Pressureless Sintering Definition and Classification

What is Pressureless Sintering?

Pressureless sintering is a thermal process that involves heating a compacted metal powder and binder mixture in a controlled atmosphere without applying external pressure. The binder is gradually removed as the temperature rises, and the metal particles fuse, creating a dense and solid component. The absence of external pressure during metal sintering allows for the preservation of intricate shapes and features, making pressureless sintering ideal for complex geometries.

Pressureless Sintering Classification

Pressureless sintering can be classified into several methods based on the atmosphere used during the metal sintering process. The most common classifications are:

- Vacuum Sintering: In vacuum sintering, the sintering process occurs in a low-pressure environment, typically below atmospheric pressure. This method reduces oxidation and minimizes the formation of voids or defects.

- Controlled Atmosphere Sintering: Controlled atmosphere sintering involves sintering in an environment with controlled gas compositions, such as nitrogen or hydrogen. This enables better control over the sintering kinetics and the elimination of surface oxides.

- Inert Gas Sintering: In inert gas sintering, an inert gas, such as argon, is used during the sintering process to prevent oxidation of the metal powder. This method ensures a high level of purity in the final product.

- Hybrid Sintering: Hybrid sintering combines the advantages of different sintering techniques, such as vacuum and controlled atmosphere sintering. This approach allows for precise control of the sintering environment, resulting in optimized material properties.

Each pressureless sintering classification has its specific benefits and applications. The choice of sintering method depends on factors such as the material being processed, desired properties, and cost considerations.

Pressureless Sintering Operation Steps

The pressureless sintering process involves several key steps to successfully transform the compacted metal powder into a fully dense component. Here is a step-by-step breakdown of the pressureless sintering operation:

Preheating

The process begins with preheating the compacted parts in a controlled atmosphere to remove residual binders and ensure uniform heating during sintering. The preheating step ensures the removal of residual binders, which could hinder proper sintering. It also helps to establish a uniform temperature distribution within the parts, minimizing thermal gradients during sintering.

Sintering

The sintering step is where the magic happens. The carefully controlled temperature profile enables the diffusion of atoms between particles, leading to particle bonding and densification. It is crucial to reach the optimal sintering temperature for the specific material to achieve the desired density and mechanical properties.

Cooling

After the sintering process, the parts are slowly cooled to room temperature. Proper cooling is essential to prevent thermal stress and maintain dimensional stability.

Post-Treatment

In some cases, post-treatment steps may be necessary to further enhance the sintered parts' properties. This can include heat treatment, surface finishing, or additional CNC machining operations. Heat treatment can improve hardness or modify microstructure, while surface finishing processes like polishing or coating provide aesthetic and functional enhancements.

Pressureless sintering Advantages

Pressureless sintering offers several advantages, making it a preferred choice in manufacturing metal injection molded parts. These include:

Near-Net-Shape Production: Pressureless sintering allows for producing complex shapes with high dimensional accuracy, minimizing the need for secondary machining operations.

Material Properties: The process yields fully dense parts with excellent mechanical properties, such as high strength, hardness, and wear resistance.

Versatility: Pressureless sintering can be applied to a wide range of materials, including stainless steel, titanium, copper alloys, and more, offering versatility in material selection.

Cost-Effectiveness: Compared to traditional manufacturing methods, pressureless sintering can save costs by reducing material waste and eliminating the need for extensive machining.

Design Freedom: The process enables the production of intricate and lightweight parts with features that would be challenging or impossible to achieve through other manufacturing techniques.

Defects and Prevention

Common Defects of Pressureless Sintering

While pressureless sintering offers many benefits, certain defects can occur. Some common defects include:

1. Porosity: Inadequate densification can result in the formation of pores within the sintered part, leading to reduced mechanical properties and increased susceptibility to corrosion.

2. Warpage: Non-uniform shrinkage during cooling can cause warpage or distortion of the final part, affecting dimensional accuracy and functionality.

3. Oxidation: Insufficient control of the sintering atmosphere can lead to the oxidation of the metal powder, resulting in surface discoloration or reduced material properties.

4. Cracking: Rapid cooling or thermal stress can cause cracking, especially in parts with complex geometries or varying thicknesses.

Prevention Methods of Pressureless Sintering Defects

To minimize and prevent these defects, various strategies can be employed:

1. Powder Quality: Ensuring the use of high-quality metal powders with appropriate particle size distribution and minimal impurities can reduce the likelihood of defects.

2. Binders and Lubricants: Selecting suitable binders and lubricants and controlling their composition and distribution within the feedstock can optimize the debinding process, reducing the risk of porosity.

3. Sintering Atmosphere Control: Maintaining a controlled atmosphere during sintering, such as vacuum or controlled gas environments, can prevent oxidation and improve overall material properties.

4. Temperature and Heating Rate Optimization: Fine-tuning the sintering temperature and heating rate can minimize thermal gradients, warpage, and cracking.

5. Cooling Rate Control: Implementing controlled cooling rates allows for gradual stress relief, reducing the risk of cracking and maintaining dimensional stability.

6. Post-Sintering Treatments: Applying appropriate post-sintering treatments like heat treatment or surface finishing can enhance material properties and address any remaining defects.

Trends and Developments

The field of pressureless sintering is continually evolving, driven by advancements in materials, equipment, and process control. Some notable trends and developments include:

Advanced Materials: New alloy compositions and metal powders with improved properties are being developed, expanding the range of applications for pressureless sintering.

Process Simulation: Computer-aided modeling and simulation techniques allow for more accurate predictions of the sintering process, enabling better process optimization and defect prevention.

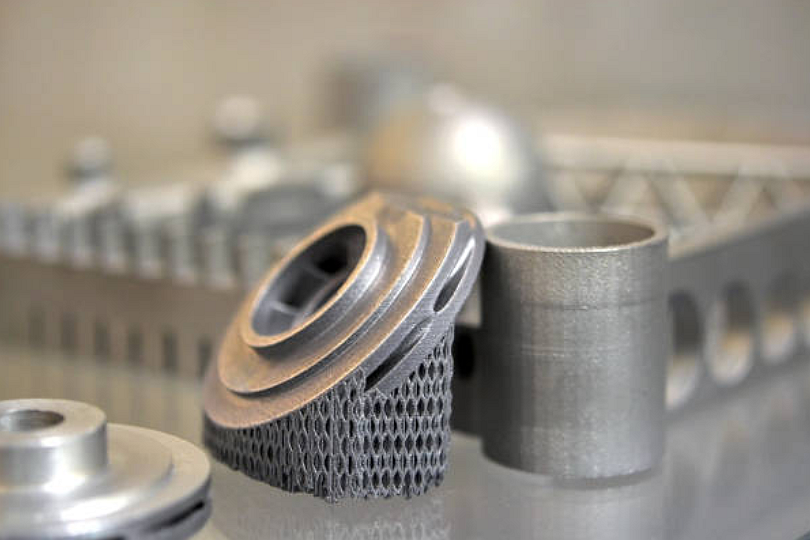

Additive Manufacturing Integration: Integrating pressureless sintering with additive manufacturing processes, such as metal 3D printing, offers new possibilities for complex part production.

Sustainability: Efforts are being made to reduce the environmental impact of pressureless sintering, such as optimizing energy usage, minimizing waste generation, and exploring greener binder systems.

Why Choose Us

Neway is your trusted partner for all your pressureless sintering needs. As an experienced and reputable metal injection molding company, we offer the following:

Exceptional Quality: We adhere to strict quality control measures, ensuring that each sintered part meets the highest performance and reliability standards.

Technical Expertise: Our team of skilled molding engineers possesses extensive knowledge and expertise in pressureless sintering, enabling us to provide customized solutions and overcome complex challenges.

State-of-the-Art Facilities: We have invested in advanced equipment and state-of-the-art facilities to ensure precise process control, consistent results, and efficient production.

Customer-Centric Approach: We prioritize customer satisfaction, collaborating closely with our clients to understand their unique requirements and deliver tailored solutions that meet their needs.

Choose Neway as your trusted partner for pressureless sintering services, and experience the benefits of our high-quality products, technical expertise, and dedicated customer support.

Don't miss our special offer! New customers can enjoy 20% off their first order. Contact us today to discuss your pressureless sintering requirements and take advantage of this exclusive deal.

nice

回复删除