Introduction

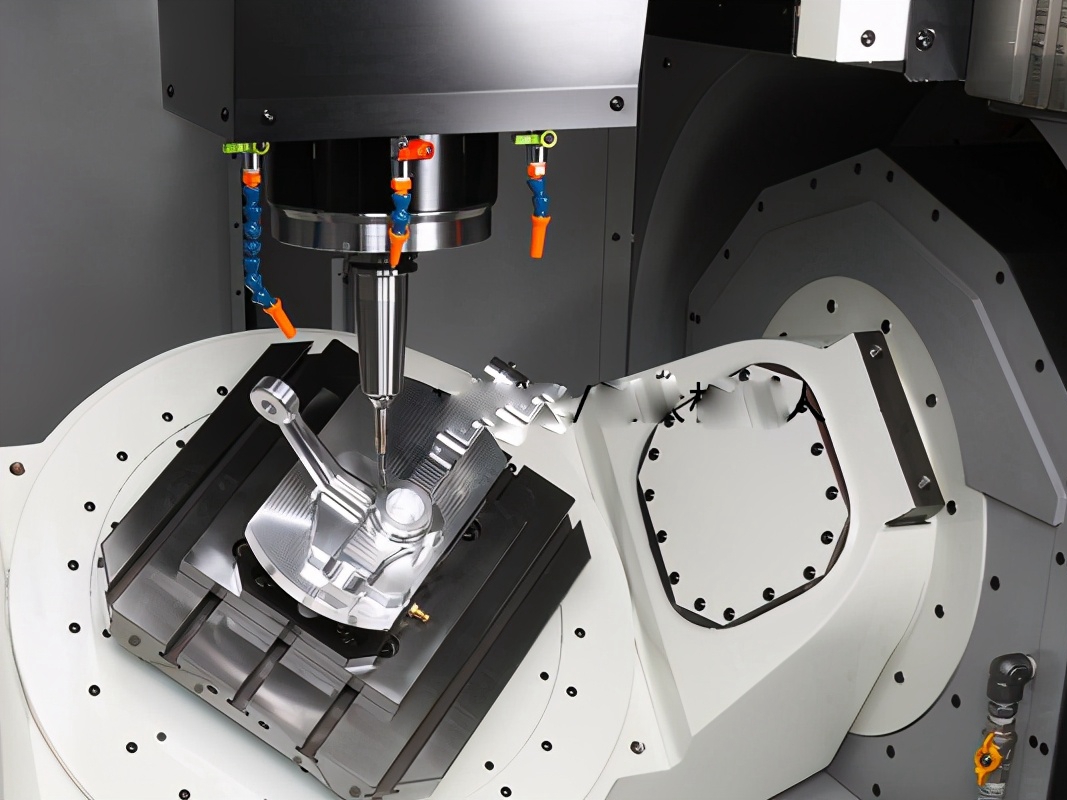

Computer Numerical Control (CNC) machining has revolutionized manufacturing by providing unmatched precision and consistency. Advanced CNC machining processes, particularly multi-axis CNC machining, significantly expand these capabilities, enabling manufacturers to create highly complex parts with exceptional efficiency and accuracy. As modern manufacturing demands intricate custom components across various industries, adopting multi-axis machining has become indispensable.

Multi-axis machining goes beyond simple linear motions, simultaneously allowing movement along multiple axes. This technology opens possibilities for manufacturing complex parts that previously were impossible or too costly to produce efficiently. Its key benefits include enhanced design flexibility, superior precision, and the ability to manufacture intricate geometries rapidly and accurately.

Understanding Multi-Axis CNC Machining

Multi-axis CNC machining refers to CNC processes that operate on more than the standard three axes (X, Y, and Z). Typical multi-axis machines include 4-axis and 5-axis systems, where additional rotational axes (such as A and B) enable intricate workpiece or cutting tool maneuvering. This complexity allows for machining at multiple angles simultaneously, dramatically improving precision and reducing setup times.

Compared to traditional 3-axis CNC machining, multi-axis machining substantially reduces the number of setups needed. While traditional machining might require repositioning the workpiece multiple times to achieve desired geometries, multi-axis machining eliminates this necessity, enhancing precision and significantly reducing production times.

Industries such as aerospace, automotive, medical devices, and consumer electronics heavily leverage multi-axis CNC machining due to its capacity to efficiently produce precise and complex components.

How Multi-Axis CNC Machining Enhances Design Flexibility

The primary advantage of multi-axis CNC machining is its ability to handle complex geometries easily. Traditional manufacturing methods might struggle to create intricate designs. Still, multi-axis machining resolves this by allowing the cutting tool to simultaneously approach the workpiece from multiple directions, ensuring complete coverage of even the most intricate details.

This approach significantly reduces the need for multiple setups. Eliminating manual repositioning minimizes risks of inaccuracies from alignment errors during repositioning, thus improving overall consistency and dimensional accuracy.

Additionally, multi-axis machining enhances precision, ensuring smoother surface finishes and tighter tolerances. Faster prototyping becomes achievable, as fewer setups and tool changes directly translate to shorter lead times, helping manufacturers rapidly iterate designs and expedite the product development cycle.

Practical Applications Across Industries

Aerospace: Multi-axis machining is essential in aerospace manufacturing, producing complex, lightweight components like turbine blades, engine parts, and structural frames. Its precision ensures safety, performance, and durability in high-stress environments.

Automotive: The automotive industry benefits significantly from multi-axis CNC machining, creating detailed parts such as cylinder heads, engine components, and transmission systems. Its speed and accuracy support mass production while meeting stringent standards.

Medical Devices: In medical device manufacturing, multi-axis CNC machining is critical for crafting intricate implants, prosthetics, and surgical instruments. It ensures biocompatibility, precise dimensions, and smooth finishes necessary for medical applications.

Consumer Electronics: Multi-axis machining enables manufacturers to create complex, miniaturized components for smartphones, laptops, and wearables. High precision is crucial to achieving functionality and aesthetic excellence in compact electronic devices.

Factors to Consider When Choosing Multi-Axis CNC Machining

Before implementing multi-axis CNC machining, manufacturers should evaluate several factors:

Complexity of Design: Intricate designs are ideal for multi-axis machining, offering capabilities unmatched by simpler machining methods.

Material Selection: Not all materials machine equally well. Multi-axis CNC machining effectively handles diverse materials, including metals like aluminum, titanium, stainless steel, plastics, and composites, each requiring specific tooling and machining parameters.

Cost Considerations: Although multi-axis CNC equipment requires a higher initial investment, it significantly reduces costs over time by enhancing efficiency, reducing setup times, and minimizing material waste.

Production Volume: Multi-axis machining suits both low-volume custom parts and high-volume precision manufacturing. Determining production volume helps manufacturers select the most cost-effective machining strategy.

Maximizing the Advantages of Multi-Axis CNC Machining

To fully leverage multi-axis CNC machining benefits, manufacturers should adhere to these best practices:

Design Optimization: Designers should create CAD models explicitly optimized for multi-axis CNC machining, considering tool accessibility, minimizing setups, and utilizing the full range of machine motion.

CAD/CAM Software Integration: Advanced CAD/CAM software is crucial for effectively programming multi-axis machines. These solutions help visualize toolpaths, simulate machining processes, and detect potential errors before machining begins, reducing costly mistakes.

Expert Consultation: Collaborating with machining experts can significantly enhance outcomes. Experienced machinists provide insights into optimal tooling, machining strategies, and troubleshooting, ensuring optimal machining performance.

Conclusion

Multi-axis CNC machining unlocks unprecedented design flexibility and manufacturing precision. By accommodating highly complex geometries, reducing setups, and enhancing accuracy, manufacturers in the aerospace, automotive, medical, and electronics industries can produce high-quality products efficiently. Integrating multi-axis CNC machining into manufacturing workflows elevates product quality, offering significant competitive advantages in today’s rapidly evolving markets.

Meta Description: Unlock unparalleled design flexibility and precision with multi-axis CNC machining services. Ideal for complex geometries across aerospace, automotive, medical, and electronics industries.

SEO Keywords: Multi-axis CNC machining, CNC machining service, precision machining, complex geometries, CNC prototyping, CNC machining accuracy, CNC manufacturing, multi-axis machining

FAQs:

What is multi-axis CNC machining, and how does it differ from standard CNC machining?

What types of parts benefit most from multi-axis CNC machining?

How does multi-axis CNC machining reduce production time?

What are the key industries that commonly use multi-axis CNC machining?

What materials are suitable for multi-axis CNC machining?

评论

发表评论