Introduction to CNC Turning

In the ever-evolving world of manufacturing, precision and efficiency are paramount. Computer Numerical Control (CNC) technology stands at the forefront of this industrial revolution, transforming raw materials into finished products with unprecedented accuracy. Among the various CNC techniques, CNC turning is a critical process widely used across numerous sectors. This technique is renowned for its ability to produce complex parts with excellent finishes and precise dimensions.

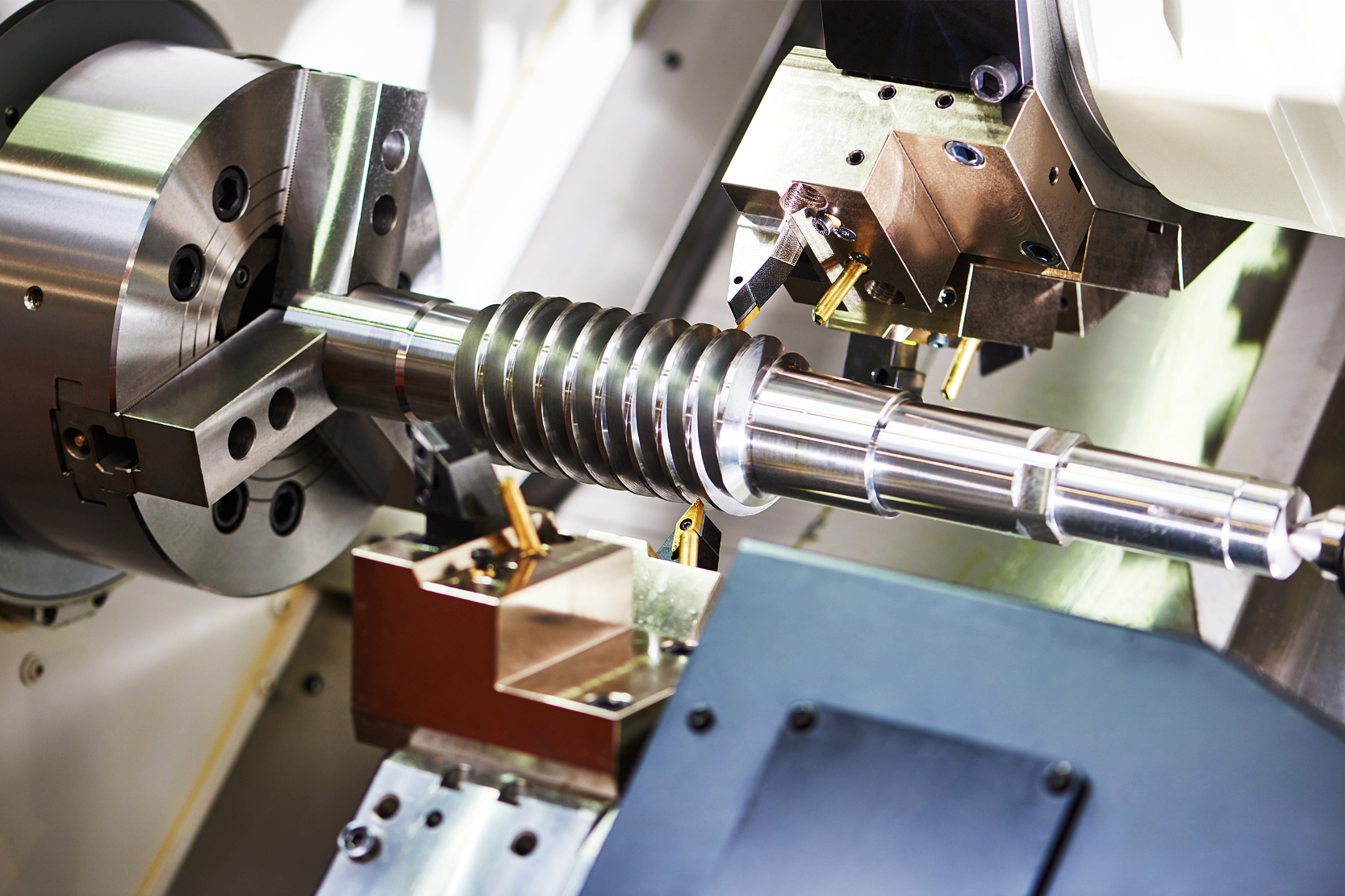

CNC turning machines, often called lathes, employ a linear cutting tool. At the same time, the workpiece rotates, creating detailed external and internal geometries on cylindrical components. The process is fundamental in producing parts that demand high precision and repeatability, making it indispensable in aerospace, automotive, and medical devices.

Understanding CNC Turning

What is CNC Turning?

CNC turning is a manufacturing process in which material bars are rotated in a chuck. At the same time, a tool is fed to the piece to remove material to create the desired shape. Essentially, the machine—commonly known as a lathe—can achieve precise machining of parts by spinning them while simultaneously using a cutting tool to carve them into a designed shape. This process can be used to perform various machining operations, including cutting, sanding, knurling, drilling, and deformation of materials, producing exact cylindrical components.

Comparison with CNC Milling

While CNC turning and CNC milling are popular forms of CNC machining, they differ significantly in their operation. CNC milling involves holding the workpiece stationary while rotating cutting tools to remove material to shape the piece. In contrast, CNC turning holds the workpiece in motion while the cutting tool remains stationary. This fundamental difference makes CNC turning ideal for creating symmetrical, round, or tubular shapes from plastics or metals.

CNC turning machines are particularly valued for their ability to produce large quantities of parts with very tight tolerances. On average, CNC turning can achieve dimensional accuracies within ±0.005 inches (±0.127 mm), essential for high-precision applications. CNC turning setups are generally quicker and more cost-effective when producing round or cylindrical parts than CNC milling.

The CNC Turning Process

The CNC turning process is a meticulously orchestrated series of steps that transform a raw material into a finished part with precision and efficiency. Here’s a closer look at each step involved in CNC turning:

1. Design and CAD Model Creation

Before any physical machining takes place, the process begins in the digital realm. Engineers and designers use Computer-Aided Design (CAD) software to develop and finalize the part's design. This model includes all the necessary specifications, dimensions, and geometries. The CAD file serves as the blueprint for the machining process.

2. Selection of Materials and Tools

Choosing the suitable material for the part depends on the application’s requirements, such as strength, flexibility, corrosion resistance, and thermal stability. Common materials used in CNC turning include metals like aluminum, steel, and brass, as well as plastics like nylon and acrylic. Additionally, selecting the appropriate cutting tools, such as lathes, drills, and finishers, is essential for effective machining.

3. Setting Up the CNC Machine

Setup involves loading the CAD file into the CNC machine’s computer and translating it into a machine-readable format. Technicians then prepare the CNC lathe by securely mounting the workpiece into the chuck and ensuring all tools are correctly aligned and calibrated. This setup is critical for maintaining the high precision required in CNC turning.

4. The Actual Turning Process

The turning process can begin with the machine being set up and the design being loaded. The CNC lathe spins the workpiece at high speeds. At the same time, the stationary cutting tool is moved along various axes to remove material according to the CAD design. Coolant is often applied to the cutting area throughout this process to reduce heat and friction that could compromise the part’s integrity.

5. Post-Processing Steps

Once the turning is complete, the part may undergo various post-processing steps to achieve the desired finish and dimensions. These can include deburring (to remove sharp edges), polishing, and additional inspections to ensure the part meets all specifications. The dimensional accuracy of CNC-turned parts is typically within ±0.005 inches, allowing for precise and consistent production.

6. Quality Control and Inspection

Quality control is integral to the CNC turning process. Using tools such as calipers, micrometers, and coordinate measuring machines (CMM), technicians perform detailed inspections to verify that the part meets all specified tolerances and quality standards. This step ensures that each component is suitable for its intended use, maintaining the high reliability expected from CNC machining.

Applications of CNC Turning

CNC turning is a versatile manufacturing process used across various industries to produce high-precision components. Its ability to efficiently create parts with complex geometries and excellent surface finishes makes it indispensable. Below are some critical applications of CNC turning, demonstrating its widespread utility and significance:

1. Aerospace Industry

CNC turning is used in aerospace to manufacture critical components such as bushings, fasteners, and manifolds. These parts often require materials that withstand extreme conditions like high temperatures and pressure. The precision of CNC turning ensures these components are reliable and conform to strict aerospace standards, contributing to the safety and functionality of aircraft.

2. Automotive Industry

The automotive industry relies on CNC turning to produce durable and precise parts such as axles, shafts, and transmission components. CNC turning facilitates the production of these parts at high volumes and with consistent quality, which is crucial for the automotive manufacturing process where both durability and precision are paramount.

3. Medical Devices

CNC turning is crucial in the medical field for creating surgical tools, implants, and other equipment like orthopedic joints and dental components. Combining biocompatible materials and achieving the stringent tolerances required for medical devices makes CNC ideal for this sector.

4. Consumer Electronics

The consumer electronics industry benefits from CNC turning in the manufacturing of components such as connectors, enclosures, and knobs. These parts often require high precision and aesthetic finishes, qualities that CNC turning can provide. This process allows for the mass production of consistent, high-quality parts integral to electronic device functionality and design.

5. Customization Capabilities

Beyond these industries, CNC turning’s real value is its ability to be tailored for custom jobs. Whether for small batch productions or larger runs, CNC turning setups can be adjusted to meet specific requirements, allowing manufacturers to innovate and produce unique, customized solutions for various applications.

The applications of CNC turning are extensive and touch nearly every facet of modern manufacturing. Its integration into production lines across different sectors is a testament to its flexibility, precision, and efficiency. This capability drives innovation and enhances the reliability and performance of the products we use daily, underscoring the critical role CNC turning plays in contemporary industry.

Materials Commonly Used in CNC Turning

The choice of material for CNC turning is crucial. It varies based on the application's specific requirements, such as strength, heat resistance, electrical conductivity, and cost. Here is an overview of some of the most commonly used materials in CNC turning, each offering unique properties that make them suitable for different manufacturing needs:

1. Metals

Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for aerospace and automotive parts due to its good strength-to-weight ratio. It's also easy to machine, which reduces production time and costs.

Stainless Steel: Known for its strength and resistance to corrosion and heat, stainless steel is frequently used in medical devices and food processing equipment. It's harder to machine than aluminum but offers excellent durability.

Brass: With its low friction and spark resistance, brass is often used in applications requiring electrical conductivity and corrosion resistance, such as gears, valves, and fittings.

Titanium: Solid and lightweight, titanium is often used in aerospace applications and medical implants. It's more challenging for machines but provides high performance in harsh environments.

2. Plastics

Nylon: Durable and resistant to abrasion, nylon is commonly used for gears, bearings, and fixtures. It's less costly than metals and offers good insulation properties.

Acetal (Delrin): Known for its stiffness, low friction, and dimensional stability, Acetal is suitable for precision parts used in mechanical applications.

PTFE (Teflon): PTFE is best known for its high heat resistance and slippery surface. It is ideal for parts that withstand extreme temperatures and reduce friction, such as seals and insulators.

3. Composites

Carbon Fiber-Reinforced Polymers: These materials are prized for their exceptional strength-to-weight ratio and are frequently used in the aerospace, automotive, and sporting goods industries. They are challenging to machine but provide superior performance where weight is critical.

Choosing the Right Material

The selection of material affects the machining process and the finished part's performance and longevity. Factors to consider include:

Mechanical Properties: Such as tensile strength, hardness, and impact resistance.

Thermal Properties: Important for applications involving high temperatures.

Cost: Especially significant in large-scale production.

Machinability: Some materials are more accessible to machines than others, affecting the speed and cost of production.

The extensive range of materials available for CNC turning allows it to serve various industries and applications, each with unique demands. Understanding each material's properties and benefits helps make informed decisions that optimize the performance, cost, and manufacturability of the parts produced.

Innovations and Future Trends in CNC Turning

Recent Advancements

CNC turning has seen several technological advancements that enhance precision, efficiency, and automation. High-speed turning centers now feature more advanced tooling and multi-axis capabilities, allowing for the machining of complex parts in fewer setups and shorter cycle times.

Automation has been integrated into CNC turning with robotic loaders and unloaders, which streamline operations and reduce labor costs. Additionally, software improvements in CAM systems now offer more intuitive programming and better optimization of machining processes.

Future Trends

The future of CNC turning will likely be shaped by further integration with artificial intelligence (AI) and the Internet of Things (IoT). Through adaptive learning, AI can predict machine failures, optimize tool paths, and improve quality control processes.

IoT connectivity in CNC machines enables real-time monitoring and data collection. This data can be used to analyze performance, predict maintenance needs, and enhance overall manufacturing efficiency.

Sustainable manufacturing practices also influence CNC turning, with increased emphasis on reducing waste and energy consumption. It includes using more environmentally friendly materials and recycling metal scraps.

Potential Impacts

These innovations are expected to dramatically increase production capacities while minimizing errors and waste, leading to cost savings and improved product quality. As machines become more intelligent and more interconnected, the role of the CNC operator will evolve, requiring new skills in IT and data management.

Conclusion

CNC turning is a fundamental aspect of modern manufacturing, and it is known for its precision, efficiency, and versatility. Throughout this article, we've explored the CNC turning process, its benefits, applications, and the materials commonly used. With ongoing advancements and the potential for increased automation and data integration, CNC turning will continue to be a critical technology in manufacturing, driving innovations and improvements in a wide range of industries.

Whether you are in aerospace, automotive, medical, or any other field requiring high-quality, precision-machined parts, CNC turning offers a reliable solution that is likely to evolve and improve further, making it a technology worth watching in the coming years.

What We Can Do In CNC Manufacturing

We want to learn more about how CNC turning can benefit your manufacturing needs. Contact Neway today to discuss your project with our experts. We deliver high-quality, precision CNC turning services tailored to your specifications. Visit our website to get started on your next project!

评论

发表评论