Superalloy Parts Vacuum Investment Casting

Superalloys, a class of metals known for their exceptional strength and resistance to thermal degradation, play a pivotal role in the modern world. These materials are indispensable in sectors that demand high performance under extreme conditions, such as aerospace, energy, and automotive industries. The unique properties of superalloys - including their ability to maintain structural integrity at high temperatures, resist corrosion, and withstand significant stress - make them ideal for critical components ranging from jet engine parts to power generation turbines.

However, manufacturing parts from superalloys presents significant challenges. The very properties that make these materials valuable make them difficult to work with. Their high melting points, tendency to react with casting materials, and complex geometries required for end-use applications complicate the manufacturing process, requiring precision, expertise, and advanced technology.

Enter vacuum investment casting, a sophisticated manufacturing technique tailored to meet these challenges head-on. This process produces complex, high-precision superalloy parts with exceptional mechanical properties and surface finishes. Vacuum investment casting mitigates common issues associated with superalloy fabrication, such as porosity and oxidation, by creating a controlled environment that enhances the material properties and fidelity of the final product.

Understanding Superalloys

As their name suggests, Superalloys are metals with superior mechanical strength and resistance to surface degradation, especially in high temperatures and pressures. These alloys are engineered to thrive under stress, making them indispensable in applications where failure is not an option. The defining characteristics of superalloys include:

High Strength: Superalloys maintain their structural integrity under extreme stress and temperatures, where other materials would falter.

Resistance to Thermal Creep Deformation: They can withstand prolonged exposure to high temperatures without deforming.

Stability Under Extreme Temperatures: Superalloys are designed to perform reliably in low- and high-temperature environments, resisting thermal fatigue and maintaining their properties over a wide temperature range.

Corrosion Resistance: These materials are engineered to resist oxidation and corrosion, ensuring longevity even in harsh chemical environments.

Superalloys are predominantly categorized based on their primary alloying element. The most common types include:

Nickel-based Superalloys: The most widely used class, known for excellent mechanical strength and resistance to thermal creep. They are ideal for high-temperature applications like jet engines and gas turbines.

Cobalt-based Superalloys: Renowned for their ability to maintain strength at high temperatures and resist thermal fatigue. Cobalt-based alloys are commonly used in gas turbine blades and surgical implants.

Iron-based Superalloys: These offer a cost-effective alternative with good mechanical properties and are often employed in industrial heating applications where extreme temperatures are a factor.

The key applications of superalloys span across various critical components in demanding sectors:

Aerospace: Turbine blades, discs, and other engine components are made from superalloys to withstand the extreme temperatures and pressures encountered during flight.

Energy: In the energy sector, superalloys are used in gas turbines and nuclear reactors due to their high-temperature capability and corrosion resistance.

Automotive: High-performance superalloy materials are used in exhaust systems and turbochargers, enhancing efficiency and performance.

Medical: Superalloys, especially those based on cobalt, find applications in medical implants due to their biocompatibility and strength.

Overview of Vacuum Investment Casting

Vacuum investment casting is a pinnacle of precision manufacturing, especially for materials as demanding as superalloys. This process, an advanced form of the traditional investment casting method, involves creating a detailed wax model of the desired part encased in a ceramic shell. The wax is melted upon hardening, leaving a perfect cavity for the metal pour. The critical distinction in vacuum investment casting lies in the environment where the metal is melted and poured: a vacuum. This crucial step mitigates the common issues associated with casting superalloys, such as porosity and oxidation, by removing air and other gases from the equation.

Basic Principles of Investment Casting

Investment casting, also known as lost-wax casting, has been a staple in metalworking for centuries, prized for its ability to produce components with intricate shapes, fine details, and excellent surface finishes. The process begins with creating a wax model, a replica of the final part. This model is coated with a refractory ceramic material to form a mold. Once the ceramic material hardens, the wax is melted, leaving a mold cavity in the shape of the part.

Introduction to Vacuum Investment Casting

Vacuum investment casting takes this process further by introducing a vacuum environment during the metal pouring phase. This innovation is particularly beneficial when working with reactive metals like superalloys. By reducing the presence of gases, the vacuum ensures that the molten metal remains pure and free from defects that could compromise the integrity of the final product.

Advantages of Vacuum Investment Casting for Superalloys

Vacuum investment casting offers several significant advantages over traditional methods when it comes to working with superalloys:

Improved Mechanical Properties: The absence of gases in the casting process minimizes porosity and other defects, resulting in parts with superior mechanical properties.

Superior Surface Finish: Vacuum casting produces components with exceptionally smooth surfaces, reducing the need for additional finishing processes.

Complex Geometry Production: This method allows for creating parts with complex geometries that would be difficult or impossible to achieve with conventional casting or machining processes.

Enhanced Material Purity: The vacuum environment protects the molten superalloy from contamination, ensuring the material's inherent properties are fully realized in the final part.

The Vacuum Investment Casting Process

The vacuum investment casting process is a refined technique meticulously designed to manufacture parts from superalloys and other high-performance materials. This process involves several critical stages, each contributing to producing parts with exceptional detail, precision, and material properties. Here's a step-by-step breakdown of vacuum investment casting, tailored explicitly for superalloys.

Mold Design and Wax Pattern Creation

Designing the Mold: The process begins with creating a detailed 3D model of the part to be cast. This model is used to craft a precise mold, often made from aluminum or another durable material, to shape the wax patterns.

Wax Pattern Production: Molten wax is injected into the mold, forming a wax replica of the final part. These wax patterns are then assembled onto a wax tree, ensuring that multiple parts can be cast simultaneously, optimizing production efficiency.

Creating the Ceramic Shell

Shell Building: The wax tree is dipped into a ceramic slurry and coated with a fine, refractory material. This process is repeated multiple times, building a thick ceramic shell around the wax patterns. Once the shell dries, it's ready for the next phase.

Wax Removal and Mold Preheating

Dewaxing: The ceramic shell is placed in a steam autoclave or a heated chamber to melt and drain the wax, leaving behind a hollow cavity in the shape of the desired parts.

Preheating: The ceramic mold is preheated to a specific temperature before casting. This step is crucial for superalloys, as it minimizes thermal shock and ensures the molten metal flows smoothly, filling every mold detail.

Vacuum Melting and Casting

Melting Under Vacuum: The superalloy material is placed in a crucible inside a vacuum chamber, where it is melted. The vacuum environment is essential here, as it prevents oxidation and removes gases that could create porosity in the casting.

Pouring: The molten superalloy is carefully poured into the preheated ceramic mold, which is still under vacuum. This controlled environment ensures the metal solidifies with minimal defects and superior mechanical properties.

Post-Processing

Cooling and Shell Removal: The mold is allowed to cool after the metal solidifies. The ceramic shell is then broken away, revealing the metal parts cut from the tree.

Heat Treatment: Superalloy parts often undergo heat treatment to optimize their mechanical properties. This process involves controlled heating and cooling cycles tailored to the specific alloy and desired outcomes.

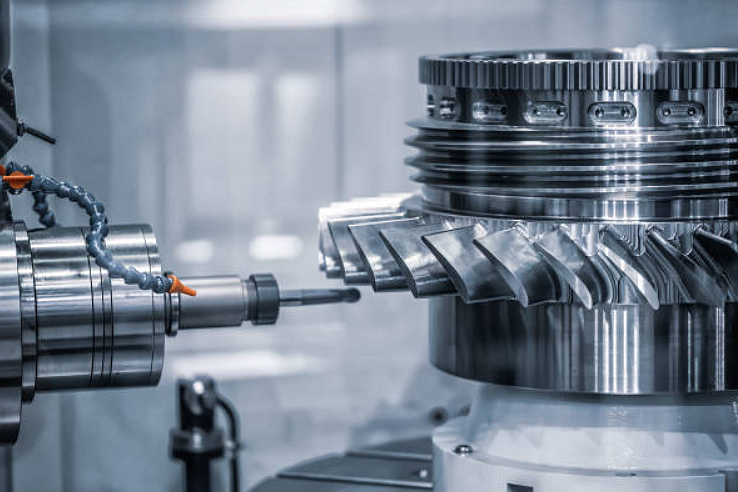

Machining and Finishing: The cast parts are CNC machined to achieve the final dimensions and tolerances required for the application. Despite the high accuracy of vacuum investment casting, some machining is often necessary for critical dimensions. Tolerances as tight as ±0.005 inches can be achieved, ensuring the parts meet stringent specifications.

HIP (Hot isostatic pressing): This process begins with densifying the component inside a high-pressure vessel. The vessel is then filled with an inert gas, usually argon, heated and pressurized to levels where the material's microstructure is optimized. This combination of heat and isotropic (equal in all directions) pressure effectively eliminates porosity. It increases the density of the material, resulting in parts with superior mechanical properties, durability, and longevity.

Inspection and Quality Control: The last step involves thoroughly inspecting and testing the parts to ensure they meet all quality standards. X-ray imaging and dye penetrant inspection detect any internal or surface defects.

Vacuum Casting vs. MIM, SLM, HIP Processes

The manufacturing of high-temperature alloys, essential for applications requiring exceptional performance under extreme conditions, can be achieved through various advanced processes. Among these, vacuum investment casting stands out for its precision and material quality. However, understanding its position relative to other manufacturing technologies—Metal Injection Molding (MIM), Selective Laser Melting (SLM), and Hot Isostatic Pressing (HIP)—is crucial for selecting the optimal method for specific applications.

Vacuum Investment Casting

Vacuum investment casting is renowned for its ability to produce parts with intricate geometries and excellent surface finishes. This process is particularly advantageous for superalloys, as the vacuum environment significantly reduces defects like porosity and oxidation, ensuring the integrity and performance of the cast parts. Ideal for small to medium-sized production runs, vacuum casting offers flexibility in design and material choice, making it a preferred option for aerospace, medical, and automotive industries.

Metal Injection Molding (MIM)

Metal Injection Molding MIM combines the flexibility of plastic injection molding with the strength and integrity of metal parts. MIM offers precision and scalability and is suitable for producing small, complex shapes in high volumes. However, regarding superalloys, MIM might sometimes provide a different level of material purity or mechanical properties than vacuum investment casting due to potential issues with binder removal and alloy homogeneity.

Selective Laser Melting (SLM)

SLM, a type of additive manufacturing or 3D printing, builds parts layer by layer using a laser to melt and fuse metallic powders. SLM allows for creating highly complex structures, including internal features that are impossible to achieve with other methods. While it offers unparalleled design freedom, SLM can sometimes result in parts with higher residual stresses and less predictable material properties, especially when working with superalloys.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a process used to improve metals' mechanical properties and density by uniformly applying high pressure and temperature around the material. While not a shaping process, HIP is often used with other manufacturing methods to eliminate porosity and improve part integrity. HIP can enhance material characteristics for superalloys but requires additional steps and costs, making it less efficient for complex part production than vacuum investment casting.

Comparison

Design Flexibility: Vacuum casting and SLM offer the highest design flexibility, with SLM leading the creation of complex internal structures. MIM also provides good design flexibility but is more suited to smaller parts.

Material Properties: Vacuum investment casting and HIP (as a post-process) enhance material properties and integrity, especially for superalloys. MIM and SLM may need additional processing to achieve the same material homogeneity and mechanical strength.

Production Volume and Efficiency: MIM excels in high-volume production due to its scalability. SLM's additive nature makes it less dependent on volume but can be time-consuming for large parts. Vacuum casting offers a balance, efficiently producing small to medium batches with high precision.

Cost Considerations: The cost-effectiveness of each process depends on the production volume, part complexity, and specific material requirements. Vacuum casting often provides a cost-efficient solution for medium-volume, complex parts in superalloys, avoiding the high initial tooling costs of MIM and the slow build rates and material costs of SLM.

Considerations of Vacuum Investment Casting for Superalloy Parts

Vacuum investment casting is a sophisticated manufacturing process that offers a blend of precision, versatility, and material integrity, making it ideal for creating complex parts from superalloys. However, like any specialized technique, it has advantages and shortcomings that manufacturers must consider.

Advantages

Superior Material Properties: The vacuum environment significantly reduces the presence of gases and contaminants during casting, resulting in parts with minimal porosity and enhanced mechanical properties. It is particularly beneficial for superalloys, where integrity and performance are critical.

Complex Geometries and Precision: Vacuum investment casting allows for producing parts with intricate designs and fine details. The process can achieve tight tolerances (e.g., ±0.005 inches), making it suitable for components that require precise dimensional accuracy.

Excellent Surface Finish: Parts produced through vacuum investment casting often require minimal post-processing, thanks to the process's ability to achieve superior surface finishes. It can lead to cost savings in finishing steps such as machining or polishing.

Material Efficiency: The process minimizes waste, as the molten material can be precisely controlled and directed into the mold. This efficiency is especially advantageous when working with expensive superalloys.

Versatility in Material Choice: While particularly beneficial for superalloys, vacuum investment casting is not limited to these materials. It can be used with a wide range of metals, offering manufacturers flexibility in material selection.

Shortcomings

Cost Considerations for Small Batches: The initial setup and tooling for vacuum investment casting can be costly, making it less economical for small production runs. The process becomes more cost-effective at medium to large volumes.

Limitations on Part Size: While vacuum investment casting is excellent for small to medium-sized parts, the size of parts that can be produced is limited by the capacity of the vacuum chamber and the equipment used. Significant components may require alternative manufacturing methods.

Complexity of Process Control: Achieving the desired results with vacuum investment casting requires precise control over many variables, including temperature, vacuum level, and pouring speed. This complexity can increase the process's learning curve and operational demands.

Lead Times: Due to the multiple stages involved in vacuum investment casting, including mold making, wax pattern production, and ceramic shell construction, the lead times can be longer than other manufacturing processes.

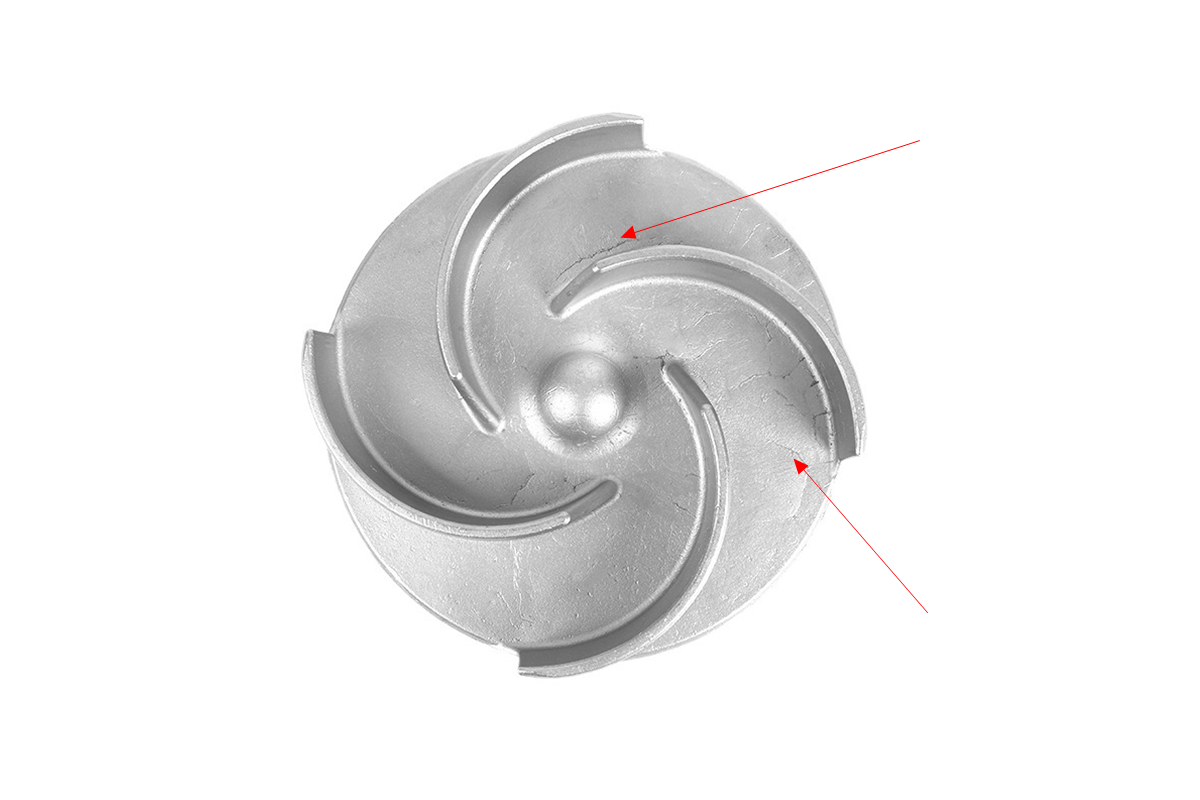

Potential for Ceramic Shell Cracking: The ceramic shell must withstand thermal stress during the metal pouring and solidification phases. If not properly controlled, this can lead to defects in the final part due to cracking of the shell.

Superalloy Manufacturing

We can use MIM, SLM, vacuum casting, HIP, and other technologies to manufacture high-temperature metal parts such as nickel, cobalt, and tungsten. At the same time, HIP technology can also be selected as a post-processing process to improve the density of the blank and eliminate pores and internal defects.

Metal Injection Molding (MIM) Service

Superalloy SLM 3D Printing Service

评论

发表评论