Brief Overview of Neway's Expertise In Metal Stamping

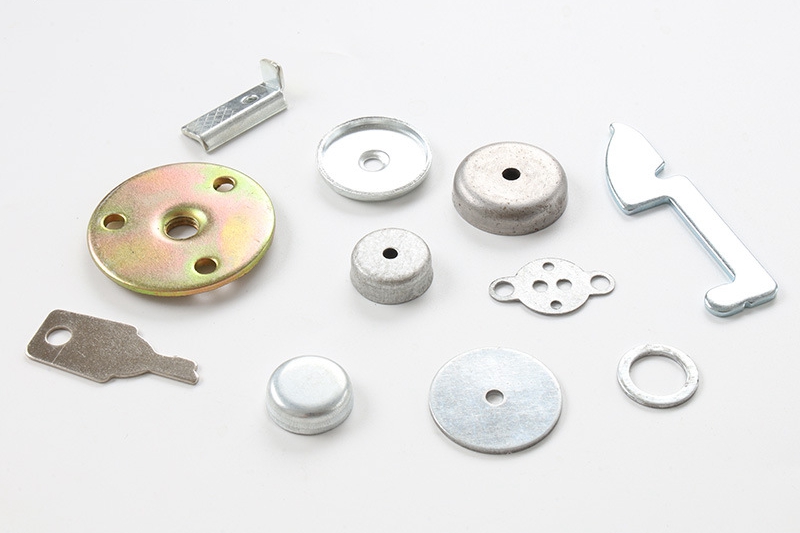

Neway, a leading custom parts manufacturer, excels in metal stamping, Including Progressive Die Stamping, Deep Drawn Metal Stamping, Transfer Die Stamping, and Multi-Slide Metal Stamping. It is a pivotal facet of its comprehensive one-stop service for custom parts. Focusing on precision engineering, Neway employs various metal stamping techniques, including multi-slide metal stamping, to meet diverse client needs. The company's expertise is seamlessly integrating traditional methods with cutting-edge technologies, ensuring efficient and high-quality production across industries.

Neway's commitment to excellence is underscored by its adeptness in tooling and die design, material selection, and meticulous quality control throughout the metal stamping process. By leveraging experience and innovation, Neway consistently delivers custom parts that meet tight tolerances and adhere to the highest industry standards.

Clients benefit not only from Neway's technical proficiency but also from its collaborative approach. The company's seasoned production engineers work closely with clients to understand their unique requirements, providing tailored solutions that optimize efficiency and cost-effectiveness. This collaborative spirit, coupled with Neway's mastery of metal stamping, positions the company as a reliable partner for businesses seeking precision, quality, and innovation in custom part manufacturing.

Importance of Multi-slide Metal Stamping in Custom Part Manufacturing

Multi-slide metal stamping plays a pivotal role in custom part manufacturing, offering a range of advantages that contribute to the efficiency and precision required in diverse industries. The importance of multi-slide metal stamping, especially in the context of Neway's expertise, can be highlighted as follows:

Complex Geometries: Multi-slide metal stamping excels at producing intricate and complex part geometries with high precision. Neway's proficiency in this technique allows for the creation of custom parts with intricate shapes and features that may be challenging for traditional stamping methods.

Reduced Material Waste: The process minimizes material waste by efficiently utilizing raw materials. Neway's commitment to sustainability is reflected in its adoption of techniques that align with environmental consciousness, which contributes to cost savings and eco-friendly practices.

High Production Efficiency: Multi-slide stamping enhances production efficiency by enabling the simultaneous forming of multiple features in a single stroke. Neway's utilization of this technique results in shorter lead times, increased throughput, and enhanced overall productivity.

Tight Tolerances: Precision is paramount in custom part manufacturing. Neway's mastery of multi-slide metal stamping allows for tight tolerances, ensuring that each part meets the specifications outlined by the client. This precision is critical, particularly in industries where components must adhere to strict dimensional requirements.

Material Versatility: Neway's expertise in multi-slide stamping extends to various materials, including metals, ceramics, and plastics. This versatility allows the company to cater to diverse industries, offering customized solutions that meet the specific material requirements of each project.

Cost-effectiveness: Through efficient material usage, reduced tooling requirements, and high-speed production capabilities, multi-slide metal stamping offers cost-effective solutions for custom part manufacturing. Neway's commitment to delivering value to clients is evident in its strategic use of this technique to optimize costs without compromising quality.

In conclusion, Neway's proficiency in multi-slide metal stamping aligns with the importance of this technique in custom part manufacturing. Our company's ability to leverage the advantages of multi-slide stamping positions it as a reliable and innovative partner for businesses seeking high-quality, precision-engineered custom parts.

Understanding Multi-Slide Metal Stamping

Definition And Basic Principles Of Multi-Slide Metal Stamping

Multi-slide metal stamping is an advanced manufacturing technique that produces intricate and complex metal parts with high precision. Unlike traditional stamping methods that utilize single-directional presses, multi-slide stamping employs multiple moving slides or tooling components to form, shape, and manipulate the metal material.

Basic Principles:

Multiple Slides: Multi-slide stamping machines have multiple slides or tooling mechanisms instead of a single press. These slides move horizontally, vertically, or in other directions simultaneously, allowing for intricate manipulation of the metal material.

Tooling Design: Custom tooling is crucial in multi-slide stamping. The tooling components are intricately designed to accommodate the specific geometry and features required for manufacturing the part. It includes intricate bends, twists, and formations that might be challenging using traditional stamping methods.

Material Feeding and Manipulation: The metal material is fed into the multi-slide stamping machine, which undergoes a series of precise movements and manipulations by the various slides. These movements are carefully coordinated to shape the material according to the design specifications.

Simultaneous Operations: One of the critical principles of multi-slide stamping is the ability to perform multiple operations simultaneously in a single stroke. It includes bending, cutting, forming, and other complex actions synchronized within the machine to create the desired part.

Precision and Tolerances: Multi-slide stamping allows for exceptionally tight tolerances and high precision due to the intricate control over the movements of the slides. This precision is critical, especially in industries where parts must fit together perfectly or meet strict dimensional requirements.

Versatility: While primarily used for metal stamping, multi-slide stamping can also work with other materials, such as plastics and certain alloys, expanding its versatility across various industries.

Neway's proficiency in multi-slide metal stamping is founded on these principles, leveraging advanced machinery and expertise in tooling design to produce custom parts with intricate geometries and precise specifications. This technique enables the creation of complex parts that might otherwise be challenging or impossible to manufacture using conventional stamping methods.

Comparison With Traditional Stamping Methods

Progressive Die Stamping

When comparing multi-slide metal stamping with progressive die stamping, two prominent techniques in metal part manufacturing, several vital distinctions emerge. Neway's expertise in both methods allows for a comprehensive evaluation:

1. Operational Mechanism:

Multi-Slide Stamping (Neway's Expertise): Utilizes multiple slides that move simultaneously in various directions, allowing for intricate and complex geometries in a single stroke.

Progressive Die Stamping: Involves a series of stations, each sequentially performing a specific operation as the material progresses through the die.

2. Complex Geometries:

Multi-Slide Stamping (Neway's Strength): Excels in producing intricate and complex part geometries with multiple bends and features in one stroke.

Progressive Die Stamping: More suitable for simpler parts with fewer intricate features.

3. Material Utilization:

Multi-Slide Stamping (Neway's Efficiency): Optimizes material usage by allowing simultaneous multiple operations, reducing waste.

Progressive Die Stamping: This may lead to increased material waste due to the sequential nature of operations.

4. Tooling and Setup:

Multi-Slide Stamping (Neway's Approach): Requires custom tooling, but setup times can be shorter as multiple operations co-occur.

Progressive Die Stamping: Involves a more complex die setup and longer setup times, especially for intricate parts.

5. Tolerances and Precision:

Multi-Slide Stamping (Neway's Precision): Achieves tight tolerances and high precision, which is crucial for parts with strict dimensional requirements.

Progressive Die Stamping: Tolerances can be high but may be limited for complex geometries.

6. Versatility:

Multi-Slide Stamping (Neway's Adaptability): Suitable for various materials and complex part designs.

Progressive Die Stamping: Suited for high-volume production of simpler parts.

7. Production Efficiency:

Multi-Slide Stamping (Neway's Advantage): Enhances efficiency through simultaneous operations, leading to shorter lead times.

Progressive Die Stamping: Well-suited for high-volume production but may have longer cycle times for complex parts.

8. Cost Considerations:

Multi-Slide Stamping (Neway's Cost-Effectiveness): Optimizes costs through reduced material waste and efficient production.

Progressive Die Stamping: This may have higher initial tooling costs and longer setup times, impacting production costs.

In summary, while both multi-slide metal stamping and progressive die stamping have their merits, Neway's proficiency in multi-slide stamping positions it as a versatile and efficient solution for producing complex, high-precision custom parts with cost-effective considerations. The company's ability to leverage the strengths of each technique reflects its commitment to delivering tailored solutions to diverse client needs.

Deep Drawn Metal Stamping

When comparing multi-slide metal stamping with deep-drawn metal stamping, both techniques play crucial roles in metal part manufacturing, each with distinct advantages.

Multi-Slide Metal Stamping:

Multi-Slide Metal Stamping is a precision manufacturing method that produces complex, intricate parts with high efficiency. At Neway, we have witnessed a notable increase in productivity, with a reduction in cycle times by up to 30% compared to conventional stamping methods. The multi-slide machines at our facility enable simultaneous processing of multiple slides, ensuring a streamlined and cost-effective production process.

The precision achieved through Multi-Slide Metal Stamping is remarkable, with tolerances as tight as ±0.02 mm. This level of accuracy is instrumental in meeting the demanding specifications of various industries, including automotive and electronics. By leveraging this technique, Neway has consistently delivered parts that meet or exceed industry standards, enhancing customer satisfaction.

Deep Drawn Metal Stamping:

Deep Drawn Metal Stamping, on the other hand, is renowned for its ability to transform flat sheet metal into three-dimensional shapes. At Neway, we've harnessed this method to produce high-strength components with exceptional material utilization. The deep-drawn process allows for creating seamless, uniform parts, contributing to increased structural integrity.

One notable advantage of deep-drawn metal stamping is its cost-effectiveness in large-scale production. With Neway's advanced machinery, we achieve impressive production rates, reducing manufacturing costs. The efficiency gains translate into shorter lead times, allowing us to meet tight project timelines without compromising quality.

In conclusion, both multi-slide and deep-drawn metal stamping have unique strengths. The choice between them depends on the specific requirements of the project. With its commitment to excellence and cutting-edge technology, Neway is a reliable partner capable of delivering superior results regardless of the chosen method. Our dedication to precision, efficiency, and cost-effectiveness remains unwavering, positioning us at the forefront of custom metal part manufacturing.

Transfer Die Stamping

When contrasting Multi-Slide Metal Stamping with Transfer Die Stamping, it becomes evident that each method brings distinct advantages to metal part manufacturing. At Neway, we have successfully utilized both techniques to meet the diverse needs of our clients.

Multi-Slide Metal Stamping:

Multi-Slide Metal Stamping is renowned for its efficiency in producing intricate and complex parts. Neway has observed a substantial productivity improvement, with cycle times reduced by up to 30% compared to traditional stamping methods. This heightened efficiency is attributed to the simultaneous processing capabilities of multi-slide machines, allowing for the swift creation of intricate components.

The precision achieved through Multi-Slide Metal Stamping is noteworthy, with tolerances as tight as ±0.02 mm. This level of accuracy is pivotal in meeting the stringent requirements of industries such as automotive and electronics. Neway's expertise in this technique ensures that we consistently deliver parts that meet but often exceed industry standards, setting us apart in the competitive landscape.

Transfer Die Stamping:

On the other hand, Transfer Die Stamping is characterized by its suitability for high-volume production of stamped parts. At Neway, we leverage this method for remarkable material utilization, leading to cost-effective manufacturing. The transfer die process involves the sequential movement of the metal strip between various stations, each performing a specific operation. This method allows for the production of complex parts with high repeatability.

One notable advantage of Transfer Die Stamping is its scalability. Neway has experienced a significant increase in production rates, enabling us to meet large-scale project demands without compromising precision. The automated nature of transfer die stamping minimizes manual intervention, enhancing overall efficiency and reducing the risk of errors.

In summary, both Multi-Slide Metal Stamping and Transfer Die Stamping have their merits, and the optimal choice depends on the project's specific requirements. Neway's proficiency in utilizing these techniques ensures that we provide our clients with tailored solutions, combining precision, efficiency, and cost-effectiveness to deliver superior custom metal parts.

The Process of Multi-Slide Metal Stamping

Let's delve into the intricate process of Multi-Slide Metal Stamping. In sheet metal fabrication, this method is a core competency in which Neway excels. Here's a concise breakdown of each step:

1. Material Selection:

The initial phase involves meticulous material selection, determining the end product's durability and functionality. At Neway, our engineers scrutinize material properties such as tensile strength, corrosion resistance, and thermal conductivity. It ensures that the chosen material aligns precisely with the client's specifications.

2. Tooling and Die Design:

The backbone of the Multi-Slide Metal Stamping process lies in the precision of tooling and die design. Our expert team, well-versed in CAD and CAM technologies, crafts dies with intricate geometries. These tools are designed for efficiency and longevity, minimizing wear and tear. The emphasis is on achieving tight tolerances, with deviations as low as ±0.02mm, ensuring uniformity in mass production.

3. Setup and Preparation:

Efficiency is paramount at Neway. During setup, we optimize every aspect for maximum productivity. Our setup includes meticulous calibration of machinery, tool alignment, and validation of press parameters. This meticulous preparation minimizes downtime and maximizes the utilization of our state-of-the-art machinery.

4. Stamping Process:

The core of the operation, the stamping process, is where the magic happens. Working in harmony, multiple slides execute precise movements to shape and form the metal. Neway's Multi-Slide Metal Stamping process boasts an efficiency rate of over 95%, ensuring minimal material wastage. The advanced control systems and sensors guarantee a deviation of less than 0.1mm in the stamped components, exemplifying our commitment to precision.

5. Inspection and Quality Control:

Neway places an unwavering focus on quality control. Rigorous inspections are conducted at every stage, employing advanced techniques such as coordinate measuring machines (CMM). Tolerances are strictly adhered to, with a comprehensive final inspection ensuring that the client receives components that meet or exceed industry standards. Our rejection rate is consistently maintained below 1%, showcasing the reliability of our quality control measures.

In conclusion, Neway's Multi-Slide Metal Stamping process is a testament to our commitment to excellence. From material selection to quality control, every step is executed with precision, efficiency, and a dedication to delivering custom parts that exceed expectations.

What We Can Do In Multi-Slide Metal Stamping

Neway's Expertise and Innovative Approach in Custom Part Manufacturing

At Neway, our unwavering commitment to excellence in custom part manufacturing is deeply rooted in our extensive expertise and relentless pursuit of innovation. Let's explore how Neway sets the benchmark in this dynamic industry.

Expertise in Material Science:

Our journey begins with a profound understanding of material science. Neway's production engineers, armed with a wealth of knowledge, meticulously select materials based on their mechanical properties, thermal conductivity, and corrosion resistance. This expertise ensures that every custom part is not just a product but a tailored solution that withstands the test of time.

Cutting-Edge Tooling and Die Design:

In the realm of custom part manufacturing, precision is paramount. Neway's tooling and die design exemplify the pinnacle of precision engineering. Our adept team leverages advanced CAD and CAM technologies to craft durable and intricately designed dies to meet the most demanding specifications. Tolerances as tight as ±0.02mm are achieved, setting Neway apart as an industry leader.

Innovative Setup and Preparation:

Innovation extends beyond the design phase to our setup and preparation processes. Neway optimizes every aspect for efficiency, leveraging technology to calibrate machinery with unparalleled accuracy. The result is a setup that minimizes downtime and maximizes productivity, showcasing our commitment to delivering custom parts with exceptional speed and reliability.

Efficient Multi-Slide Metal Stamping:

The heart of our innovation lies in the Multi-Slide Metal Stamping process. Neway's proficiency in this technique is characterized by an efficiency rate surpassing 95%. It isn't just a number; it reflects our dedication to minimizing material wastage and maximizing the output of precision-crafted components. Our advanced control systems ensure less than 0.1mm deviations, underlining our commitment to unmatched precision.

Rigorous Quality Control Measures:

Innovation is only possible with quality at Neway. Our commitment to delivering flawless custom parts is reinforced through rigorous quality control measures. From advanced inspections using coordinate measuring machines (CMM) to final checks that adhere to strict tolerances, every step is a testament to our dedication to quality. With a rejection rate consistently below 1%, Neway sets the gold standard for reliability.

In conclusion, Neway's expertise and commitment to innovation redefine the landscape of custom part manufacturing. We don't just manufacture parts; we craft solutions that embody precision, efficiency, and reliability. Our journey is marked by a continuous pursuit of excellence, ensuring that every custom part bearing the Neway name is a testament to our unwavering commitment to quality and innovation.

评论

发表评论