Brief Overview Of Deep-Drawn Metal Stamping

Deep-drawn metal stamping is a pivotal process in metal stamping part manufacturing, offering notable advantages in terms of precision and efficiency. Neway, a leading custom stamping parts manufacturer, leverages deep-drawn metal stamping as part of its comprehensive suite of manufacturing methods.

In this process, flat sheet metal is drawn into a three-dimensional shape through progressive dies and punches. This method excels in producing complex, seamless components with high dimensional accuracy. Neway's expertise in deep-drawn metal stamping extends to various materials, including steel, aluminum, and brass.

One of the critical benefits of deep-drawn metal stamping is its ability to create parts with minimal material waste, enhancing client cost-effectiveness. It aligns with Neway's commitment to providing efficient and sustainable manufacturing solutions. The process also ensures consistent quality across large production runs, meeting the stringent requirements of diverse industries.

Neway's application of deep-drawn metal stamping spans industries such as automotive, electronics, and aerospace. By showcasing real-world examples of successful projects, your articles can highlight Neway's proficiency in delivering custom parts tailored to each client's unique specifications.

From a rapid prototyping perspective, Neway integrates deep-drawn metal stamping seamlessly into its suite of services, ensuring a smooth transition from design to production. This integration reflects Neway's dedication to offering a one-stop solution for clients seeking efficient, high-quality custom parts.

In conclusion, deep-drawn metal stamping is a cornerstone in Neway's array of manufacturing methods, embodying precision, efficiency, and versatility. By elucidating the intricacies of this process through real-world examples, your articles can effectively position Neway as an industry leader committed to delivering superior custom parts across diverse sectors.

Importance Of Deep Drawn Metal Stamping In Custom Part Manufacturing

Deep-drawn metal stamping plays a pivotal role in custom part manufacturing, offering distinct advantages that contribute to the efficiency and precision of the production process. This method, embraced by leading manufacturers such as Neway, exemplifies the synergy between innovation and functionality.

One of the critical merits of deep-drawn metal stamping is its ability to create intricate and complex shapes with remarkable precision. Neway leverages this technique to manufacture custom metal parts with tight tolerances and consistent quality, ensuring that each component meets the specifications clients require.

In the vast landscape of custom part manufacturing, efficiency is paramount. As employed by Neway, deep-drawn metal stamping excels in producing large quantities of parts swiftly and cost-effectively. The high-speed production capabilities contribute to meeting tight deadlines without compromising on quality, a testament to Neway's commitment to customer satisfaction.

Furthermore, the versatility of deep-drawn metal stamping is noteworthy. Neway harnesses this method across various industries, seamlessly adapting it to fabricate parts for automotive, aerospace, electronics, and more. The adaptability underscores Neway's dedication to providing a comprehensive one-stop service for custom parts, catering to diverse client needs.

In the competitive landscape of manufacturing, material utilization is a critical factor. Deep-drawn metal stamping minimizes material waste, aligning with Neway's commitment to sustainable practices. It not only enhances the environmental credentials of the manufacturing process but also contributes to cost savings, a reflection of Neway's strategic and forward-thinking approach.

From a practical standpoint, the longevity and durability of parts produced through deep-drawn metal stamping stand out. Neway's emphasis on quality and precision ensures that the custom parts manufactured using this method exhibit exceptional durability, meeting and often exceeding industry standards.

Basics of Deep Drawn Metal Stamping

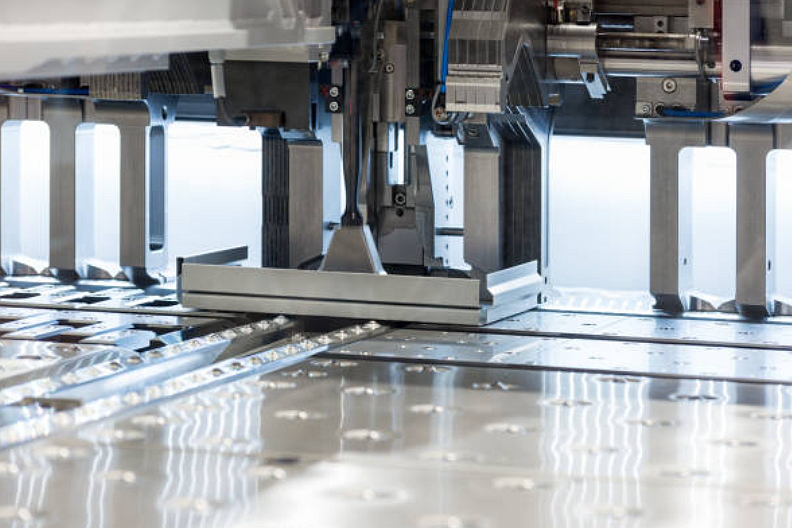

What Is Deep Drawn Metal Stamping

Deep-drawn metal stamping is a manufacturing process to create hollow, three-dimensional metal components from sheet metal. It involves placing a metal sheet over a die and using a punch to draw it into the die cavity, forming the desired shape. The metal undergoes severe deformation, stretching, and reshaping to create complex and precise geometries.

This process is beneficial for producing parts with deep or complex shapes, like cups, enclosures, cans, or automotive components such as vehicle panels and engine parts. It's cost-effective for large-scale production because it can quickly create parts with minimal material waste.

Deep-drawn metal stamping is advantageous for its high precision, repeatability, and the ability to maintain consistent wall thickness throughout the part. Additionally, it allows for a wide range of materials, including stainless steel, aluminum, copper, and various alloys, to be used in production, making it versatile for diverse industry needs.

For Neway, leveraging deep-drawn metal stamping as part of their capabilities can offer clients precision-engineered, custom-shaped metal parts with high efficiency, meeting various industry standards and demands.

Key Components Involved In Deep Drawn Metal Stamping

Deep-drawn metal stamping involves several key components to achieve precise and complex shapes. Here's a breakdown of the essential elements in this manufacturing process:

Material Selection:

Choosing a suitable material is crucial. Various metals, such as stainless steel, aluminum, copper, and alloys, can be used depending on the desired properties of the final product.

Blank Holder:

The blank holder is a component that holds the metal sheet in place during the stamping process. It ensures uniform material flow and helps prevent wrinkles or tears in the sheet.

Die:

The die is a tool or mold with a cavity designed to shape the metal into the desired form. It is a crucial component that determines the final shape and dimensions of the deep-drawn part.

Punch:

The punch is the component that exerts force on the metal sheet, pushing it into the die and forming the desired shape. The punch shape corresponds to the negative of the final part design.

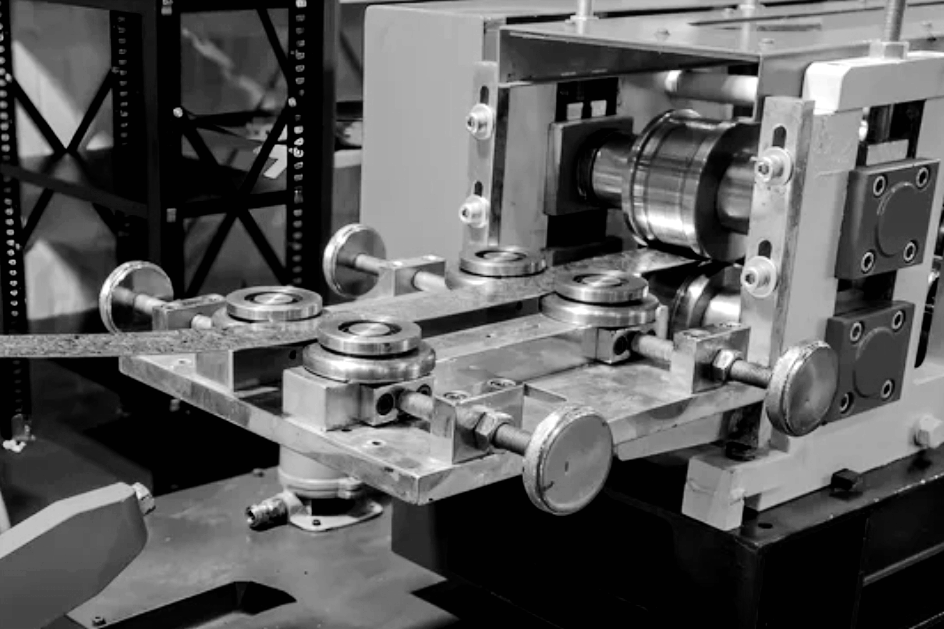

Draw Ring:

Sometimes, a draw ring controls the material flow and reduces wrinkling during the deep drawing process. It helps in maintaining the shape and integrity of the drawn part.

Lubrication:

Lubricants are applied to the metal sheet to reduce friction during the deep drawing. It facilitates smoother material flow and helps prevent damage to the tooling.

Press Machine:

A press machine provides the force necessary for the deep drawing process. The machine's tonnage and speed are critical to achieving accurate and consistent results.

Post-Processing Equipment:

After the deep drawing process, additional operations like trimming, piercing, or surface finishing may be required to meet specific design and quality requirements.

For Neway, showcasing expertise in managing these components ensures the production of high-quality, custom deep-drawn metal parts for diverse industries. By emphasizing precision, material versatility, and efficient processing, Neway can be a reliable provider of deep-drawn metal stamping services.

Comparison With Other Metal Forming Methods

Deep Drawn Metal Stamping Vs. Progressive Die Stamping

Deep-drawn metal stamping and progressive die stamping are metal-forming processes, but their approach and applications differ. Here's a concise comparison between the two:

Deep Drawn Metal Stamping:

Process Description: Drawing a flat metal sheet into a die cavity to create a three-dimensional, often hollow, component.

Complexity: Ideal for parts with deep recesses or intricate shapes, such as cups, cans, and enclosures.

Tooling: Requires a single die and punch setup. Suitable for low to medium production volumes.

Material Thickness: Well-suited for thin to moderately thick materials.

Advantages: High precision, repeatability, and suitability for complex shapes. Minimal material waste.

Progressive Die Stamping:

Process Description: Utilizes a series of dies in a sequence to progressively shape the metal strip into the final part. Each station performs a specific operation.

Complexity: Suited for parts with multiple features or intricate geometries that can be produced in stages.

Tooling: Involves a set of dies mounted on a single die set. Enables high-speed production for large quantities.

Material Thickness: Effective for thin materials. It may have limitations on the complexity of deep draws.

Advantages: High-speed production, cost-effective for large volumes, efficient for parts with multiple features.

Neway's Perspective:

Versatility: Neway's expertise in deep-drawn metal stamping and progressive die stamping provides clients a versatile range of options.

Customization: Deep-drawn stamping is ideal for clients requiring intricate shapes, while progressive die stamping suits those with high-volume needs.

Efficiency: Neway can cater to diverse client requirements by offering both processes, ensuring optimal efficiency and cost-effectiveness.

Positioning these processes as complementary allows Neway to address a broader spectrum of client needs, showcasing flexibility, precision, and scalability in their one-stop service for custom metal parts manufacturing.

Deep Drawn Metal Stamping Vs. Transfer Die Stamping

Metal stamping, deep-drawn metal stamping, and transfer die stamping are two distinct yet essential processes, each offering unique advantages in custom part manufacturing.

Deep Drawn Metal Stamping:

This precision technique, falling under the broader category of sheet metal fabrication, involves transforming flat metal sheets into three-dimensional shapes. Deep-drawn stamping excels in creating components with significant depth-to-diameter ratios using forces to draw the material into a die. Neway's expertise in sheet metal fabrication, including laser cutting and metal bending, synergizes seamlessly with deep-drawn stamping, efficiently producing complex and intricate parts.

Transfer Die Stamping:

On the other hand, Transfer Die Stamping is a method within the broader spectrum of metal stamping, focusing on high-volume production with minimal material waste. This process involves a series of stations or dies, each performing specific tasks sequentially. It is highly efficient for mass production, making it a go-to method for Neway when large quantities of custom metal parts are required. The precision and speed inherent in transfer die stamping align with Neway's commitment to providing on-demand production solutions.

Comparative Analysis:

While both methods fall within the umbrella of metal stamping, they serve different purposes. Deep-drawn stamping excels in crafting intricate designs with varying depths, making it ideal for components where depth is critical. On the other hand, transfer die stamping shines in high-volume production scenarios, ensuring cost-effectiveness and consistency in large batches.

For Neway, the versatility to seamlessly integrate deep-drawn and transfer die stamping into their one-stop custom parts manufacturing service highlights the company's commitment to meeting diverse client needs. The precision of deep-drawn stamping and the efficiency of transfer die stamping together contribute to Neway's reputation for delivering top-notch, tailor-made solutions.

By incorporating examples of successful projects undertaken by Neway using these stamping methods, we can illustrate real-world applications and showcase the company's prowess in delivering high-quality custom metal parts. This approach informs the audience and aligns with Neway's commitment to excellence and customer satisfaction.

In conclusion, deep-drawn metal stamping and transfer die stamping play pivotal roles in Neway's manufacturing capabilities. This diverse set of techniques positions Neway as a reliable and innovative one-stop service provider, capable of meeting the intricate demands of custom part production with precision and efficiency.

Deep Drawn Metal Stamping Vs. Multi-Slide Metal Stamping

Drawn Metal Stamping and Multi-Slide Metal Stamping are integral techniques within metalworking, offering distinct advantages in custom part manufacturing.

Deep Drawn Metal Stamping:

Deep-drawn stamping involves transforming flat metal sheets into three-dimensional shapes using a die. This process excels in creating parts with significant depth-to-diameter ratios, making it ideal for components requiring depth, such as cylindrical or box-shaped parts. Neway's proficiency in sheet metal fabrication, including metal bending and laser cutting, complements deep-drawn stamping, allowing for the efficient production of complex and intricate parts.

Multi-Slide Metal Stamping:

On the other hand, Multi-Slide Metal Stamping involves a specialized machine with multiple slides that simultaneously work on the metal strip, forming intricate shapes with tight tolerances. This technique is exceptionally well-suited for manufacturing smaller parts with intricate geometries, bends, and features. It's a highly efficient method, especially for producing smaller components in high volumes, where precision and repeatability are crucial. Neway's expertise in precision manufacturing methods, like multi-slide stamping, showcases the company's dedication to delivering top-tier, detailed custom parts.

Comparative Analysis:

While both deep-drawn and multi-slide metal stamping fall under the umbrella of metal stamping, they cater to different design and volume requirements. Deep-drawn stamping creates parts with notable depth, while multi-slide stamping focuses on intricate, smaller parts with complex geometries. The former is ideal for components requiring depth, while the latter produces smaller parts with intricate details.

Neway's ability to integrate deep-drawn and multi-slide stamping techniques into its comprehensive manufacturing services highlights its commitment to meeting diverse client needs. The precision and intricacy of deep-drawn stamping and the efficiency of multi-slide stamping collectively contribute to Neway's reputation for delivering high-quality, tailored solutions.

By citing examples of successful projects by Neway utilizing these stamping methods, we can elucidate their real-world applications and demonstrate the company's proficiency in delivering superior custom metal parts. This approach educates the audience and underscores Neway's dedication to excellence and customer satisfaction.

In summary, deep-drawn metal stamping and multi-slide metal stamping play vital roles in Neway's diverse manufacturing capabilities. This range of techniques positions Neway as a versatile, reliable, and innovative one-stop service provider capable of meeting various custom part production needs with precision and expertise.

Applications Of Deep-Drawn Metal Stamping

Diverse Industries Benefiting From Deep-Drawn Parts

Deep-drawn parts are crucial across diverse industries, enabling intricate designs and functionality. Here's a concise breakdown showcasing how various sectors benefit from these components:

Automotive Industry

Fuel Delivery Systems: Deep-drawn parts are integral in producing fuel tanks, delivering durability and leak-proof designs.

Exhaust Systems: Catalytic converters and exhaust pipes often incorporate deep-drawn components for structural integrity.

Transmission Components: Housings and cases for transmissions use deep-drawn parts due to their strength and dimensional accuracy.

Electronics and Technology

Smartphone Casings: Deep-drawn metal parts offer strength and lightweight properties, which are ideal for phone casings.

Connectors and Housings: Components in electronics rely on deep-drawn parts for precision and structural stability.

Aerospace Sector

Aircraft Structural Components: Various parts like airframe sections, fuselage panels, and fuel tanks benefit from deep-drawn elements, ensuring strength without excess weight.

Medical Equipment

Implantable Devices: Medical implants use deep-drawn parts due to their biocompatibility and precision in complex designs.

Diagnostic Equipment: Housings and enclosures for medical devices often employ deep-drawn parts for their robustness and intricate shapes.

Consumer Goods

Cookware: Pans and pots utilize deep-drawn metal for uniform heating and durability.

Packaging: Beverage cans and cosmetic containers benefit from deep-drawn parts for their sleek designs and strength.

General Industrial Applications

Pressure Vessels: Deep-drawn parts create pressure vessels used in various industrial applications.

HVAC Systems: Components like ducts and enclosures often use deep-drawn parts for their precision and structural integrity.

These industries benefit significantly from deep-drawn parts due to their versatility, strength, and ability to facilitate complex designs, making them indispensable in modern manufacturing processes.

What We Can Do In Sheet Metal Stamping?

.

评论

发表评论