Aluminum Die Castings and Properties

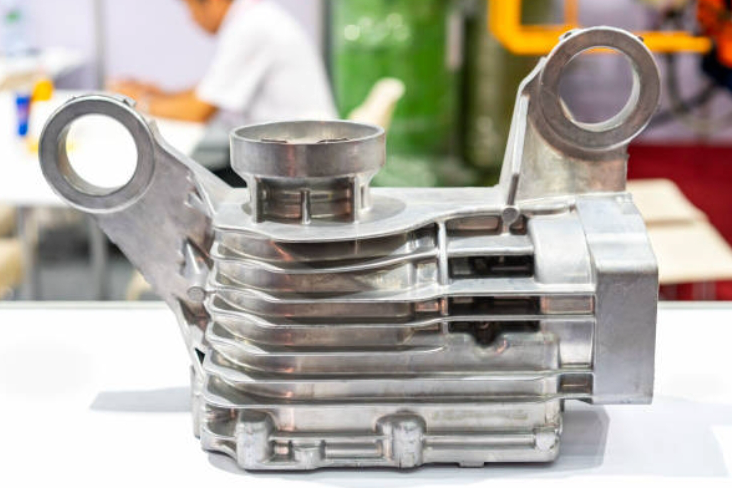

Aluminum die casting is a cornerstone in the manufacturing industry, offering a versatile solution for creating lightweight, durable parts across the automotive, aerospace, and consumer electronics sectors. This process involves forcing molten aluminum under high pressure into mold cavities, resulting in precisely detailed and dimensionally accurate components. However, the inherent properties of cast aluminum can often be enhanced to meet more rigorous demands of strength, durability, and resistance. Heat treatment plays a pivotal role in unlocking the potential of aluminum die castings to achieve superior performance characteristics.

Heat treatment of aluminum die castings is a critical post-casting process that involves controlled heating and cooling cycles to alter the metal's microstructure for improved mechanical properties. The modifications achieved through heat treatment can significantly enhance the brutal aluminum castings, strength, and stress resistance, making them more suitable for demanding applications.

This article delves into the four principal methods of heat-treating aluminum die castings: annealing, solution treatment, aging treatment, and hot and cold cycle treatment. Each method serves a unique purpose, from relieving internal stresses and stabilizing dimensions to increasing the material's strength and durability.

Understanding Aluminum Die-Casting Annealing Treatment

At the heart of improving the flexibility and reducing the internal stresses of aluminum die castings lies the annealing treatment—a heat treatment process that is as much an art as a science. This process begins by heating aluminum alloy castings to a specific temperature, generally around 300°C. What makes annealing unique is the heating and subsequent cooling phase, where the castings are allowed to return to room temperature within the furnace slowly. This gradual cooling is crucial, as it ensures the uniformity of the temperature decrease, preventing the introduction of thermal stresses that could negate the treatment's benefits.

The annealing process aims to achieve several vital improvements in aluminum casting. By heating to about 300°C, the solid solution within the aluminum alloy begins to decompose, and the second phase particles cluster together. This clustering effect has significant implications for the casting's overall properties. First, it substantially reduces the internal stress that can cause cracks or warping, especially in complex or thin-walled components. Secondly, it stabilizes the casting's dimensions, ensuring the final product maintains its intended shape and size over time and under thermal stress.

One of the most appreciated benefits of annealing is its ability to increase the plasticity of the casting. This increased plasticity means that the aluminum is more malleable and less likely to crack or break under stress, making it ideal for components that must undergo further processing, such as CNC machining or bending.

Annealing is a theoretical exercise and a practical necessity in many manufacturing scenarios. For instance, automotive components that must withstand significant stress and strain without failing often undergo annealing to ensure their reliability. Similarly, aerospace parts, where precision and durability are paramount, also benefit from this process. Through real-world applications, the annealing process has proven to be an indispensable step in producing high-quality, durable aluminum die castings.

The Role of Solution Treatment in Aluminum Die Castings

Solution treatment plays a transformative role in enhancing the mechanical properties of aluminum die castings, enabling these components to meet stringent requirements for strength, plasticity, and corrosion resistance. This process involves heating the aluminum casting to a temperature near its eutectic point—typically between 450°C to 540°C—holding it at this temperature to allow alloying elements to dissolve into a solid solution, and then rapidly cooling, or quenching, to freeze these elements in place. The precise temperature and duration of the treatment depend on the specific aluminum alloy and the desired outcomes.

Enhancing Strength and Plasticity

The primary goal of solution treatment is to maximize the dissolution of strengthening elements within the aluminum matrix. By doing so, the process significantly improves the casting's overall strength and plasticity. This improvement is crucial for parts that are subject to dynamic loads or exhibit high ductility to avoid brittle failure under stress. For example, automotive suspension components and aerospace structural parts benefit immensely from the enhanced strength and flexibility provided by solution treatment, ensuring they can withstand operational stresses without compromising their integrity.

Improving Corrosion Resistance

Another critical advantage of solution treatment is its ability to improve the corrosion resistance of aluminum die castings. The uniform distribution of alloying elements achieved through this process helps to form a more cohesive and protective oxide layer on the surface of the aluminum, safeguarding the parts against corrosive environments. This feature mainly benefits components exposed to harsh conditions, such as marine hardware and chemical processing equipment, where durability and longevity are paramount.

Practical Applications and Examples

In the automotive industry, solution-treated aluminum parts are often used in engine blocks, transmission housings, and chassis components, contributing to vehicle lightweighting without sacrificing performance or safety. Similarly, aerospace solution-treated aluminum alloys are selected for their high strength-to-weight ratio and resistance to atmospheric and chemical corrosion, making them ideal for fuselage frames, wing structures, and landing gear.

Case Studies

One notable example of the effectiveness of solution treatment can be seen in the production of high-performance bicycle frames. These frames, crafted from solution-treated aluminum alloys, offer an unmatched balance of lightness, strength, and resilience, enabling cyclists to achieve superior performance and durability.

Enhancing Properties through Aluminum Die-Casting Aging Treatment

Aging treatment, a critical process following solution treatment, significantly elevates the mechanical properties of aluminum die castings, particularly their strength and hardness. This process involves heating the solution-treated castings to a lower temperature—ranging from 120°C to 200°C—and maintaining them at this temperature for a specified duration before cooling. The aging process can be categorized into two main types: natural aging, which occurs at room temperature, and artificial aging, where the castings are heated above room temperature.

The Science Behind Aging Treatment

The essence of aging treatment lies in its ability to induce precipitation hardening. This phenomenon occurs as the supersaturated solid solution formed during solution treatment is allowed to age, leading to the formation and growth of fine precipitates throughout the aluminum matrix. These precipitates hinder dislocation movement within the metal, significantly increasing its strength and hardness. The precise mechanics of aging—whether natural or artificial—depend on the aluminum alloy's composition and the desired end properties.

Benefits of Aging Treatment

One of the most significant benefits of aging treatment is the substantial increase in the yield strength and tensile strength of aluminum die castings without a considerable loss of elasticity. This balance of strength and flexibility is crucial for components that must withstand high loads or stresses without fracturing, such as automotive powertrain components or aerospace structural elements.

Moreover, the aging process enhances the hardness of aluminum die castings, improving wear resistance. This characteristic is particularly beneficial for parts subjected to abrasive conditions or those that must maintain precise dimensions over their operational life, such as pump housings and gears.

Applications and Real-World Impact

The aging treatment has been widely applied across various industries, illustrating its versatility and effectiveness. In the automotive sector, aged aluminum die castings are used in critical safety components like airbag housings and seat frames, where high strength and reliability are paramount. Similarly, aerospace components such as brackets and fittings benefit from the enhanced strength and reduced weight offered by aged aluminum, contributing to overall aircraft performance and efficiency.

Case Study: High-Strength Aluminum Alloys in Sports Equipment

A practical example of the benefits of aging treatment can be seen in the sports equipment industry, particularly in high-performance aluminum baseball bats. These bats, treated through artificial aging processes, exhibit increased strength and resilience, allowing more excellent energy transfer to the ball. This technological advancement underscores the aging treatment's role in pushing the boundaries of material performance, demonstrating how heat treatment processes can directly translate into real-world advantages.

Hot and Cold Cycle Treatment: Precision Enhancement in Aluminum Die Castings

The hot and cold cycle treatment, also known as thermal cycling, is a sophisticated heat treatment process designed to enhance the dimensional stability and precision of aluminum die castings. This method subjects the castings to repeated cycles of heating and cooling, inducing controlled expansion and contraction in the material. The process aims to stabilize the metal's microstructure, minimizing the internal stresses that can lead to dimensional inaccuracies over time.

Mechanism and Process

The treatment begins by heating the aluminum castings to a temperature significantly lower than that used in solution treatment, typically between 100°C and 250°C. Following this, the castings are cooled rapidly to room temperature or below, often using water or air blast cooling. This cycle is repeated multiple times, with the exact number of cycles depending on the aluminum alloy's composition and the desired level of dimensional stability.

Enhancing Dimensional Stability

The primary benefit of hot and cold cycle treatment is the marked improvement in the dimensional stability of aluminum die castings. The thermal cycling process relieves residual stresses within the castings inherent to the casting and initial cooling phases. By methodically expanding and contracting the metal, the treatment helps to homogenize the casting's microstructure, reducing the likelihood of warping or deformation during subsequent machining or operational use.

Applications in Precision Manufacturing

Hot and cold cycle treatment is precious in manufacturing precision components, where even minor deviations from specified dimensions can compromise the final product's functionality. Industries such as UAV Parts manufacturing, automotive components, and precision machinery rely on this treatment to ensure the highest standards of accuracy and reliability. Engine parts, aerospace fittings, and complex mechanical assemblies benefit from enhanced stability, ensuring they fit and function as designed without requiring extensive post-processing adjustments.

Case Study: Enhancing the Stability of Precision Tools

A notable application of hot and cold cycle treatment can be seen in producing precision tools and dies for machining and forming operations. These tools are subject to significant thermal and mechanical stresses during use, which can lead to dimensional changes and reduced tool life. By employing hot and cold cycle treatment, manufacturers can produce tools with superior dimensional stability, extending their usable life and maintaining accuracy over many use cycles.

Comparison of the Four Aluminum Die Castings Heat Treatment Methods

The heat treatment of aluminum die castings is a complex and nuanced field, encompassing various techniques, each tailored to enhance specific properties of the metal. Annealing, solution treatment, aging Treatment, and hot and cold cycle treatment represent the core methods employed to achieve desired outcomes in aluminum die castings. Here, we compare these four methods regarding efficiency, suitability for different applications, and overall impact on aluminum die-casting properties.

Aluminum die casting is a preferred manufacturing process for many industries due to its ability to produce lightweight, complex, and high-strength parts. The hardness of aluminum die castings can significantly vary depending on the specific aluminum alloy used and the heat treatment processes applied. Typically, aluminum alloys used in die casting include the 300-series (like A380), 400-series, and special alloys designed to meet particular mechanical property requirements. Here's a look at the typical hardness values for some of these alloys and the enhanced hardness achievable through heat treatment, along with their typical applications:

Typical Hardness Values and Applications

Untreated Hardness: Typically, A380 aluminum alloy has a Brinell hardness of around 80 HB.

Post-Heat Treatment Hardness: Heat treatments such as solution treatment followed by quenching and aging can increase its hardness to approximately 100-110 HB.

Applications: A380 is widely used due to its excellent fluidity, pressure tightness, and resistance to hot cracking. It's commonly found in automotive parts, electronics housings, complex gear cases, and any application requiring high dimensional stability.

Untreated Hardness: A356 has a Brinell hardness of about 60-70 HB.

Post-Heat Treatment Hardness: With T6 heat treatment (solution heat treatment, quenching, and aging), the hardness can reach up to 80-90 HB.

Applications: A356 is often used for automotive and aerospace applications, including wheels, chassis components, and aircraft parts, where higher strength and corrosion resistance are needed.

AlSi10Mg Aluminum Alloy (for 3D printed parts):

Untreated Hardness: Approximately 70 HB.

Post-Heat Treatment Hardness: Can be increased to around 100 HB with proper heat treatment.

Applications: Ideal for parts that require good strength, weight reduction, and thermal properties, such as engine components, heat sinks, and structural aerospace parts.

Enhanced Hardness through Heat Treatment

Heat treatment processes like annealing, solution treatment, aging, and hot and cold cycle treatments are critical for enhancing the mechanical properties of aluminum die castings. These processes can increase hardness, which improves wear resistance, fatigue life, and overall durability of the parts. The specific process chosen depends on the alloy composition and the desired properties of the final product.

For instance, the T6 heat treatment, involving solution heat treatment followed by aging, is particularly effective for 300-series and 400-series aluminum alloys, enhancing their hardness and strength. It makes the T6-treated parts highly suitable for applications where mechanical properties such as strength, durability, and fatigue resistance are critical.

Efficiency

Annealing is relatively time-consuming due to the slow cooling phase, but it effectively reduces internal stresses and improves flexibility.

Solution Treatment requires precise temperature control and rapid cooling, making it less efficient in energy consumption but highly effective in dissolving alloying elements to enhance strength and corrosion resistance.

Aging Treatment can be considered highly efficient, especially natural aging, as it occurs at room temperature without significant energy input. Artificial aging, while requiring heat, significantly enhances strength and hardness in a relatively short timeframe.

Hot and Cold Cycle Treatment could be more efficient due to the repeated heating and cooling cycles. However, its ability to improve dimensional stability and stress relief makes it invaluable for precision components.

Suitability for Different Applications

Annealing is best suited for applications requiring improved machinability and ductility, such as automotive components that require further shaping or forming.

Solution Treatment, like aerospace and high-performance automotive parts, is ideal for parts needing high strength, flexibility, and corrosion resistance.

Aging Treatment is tailored for applications demanding enhanced mechanical strength and hardness, such as safety-critical parts in the automotive and aerospace industries.

Hot and Cold Cycle Treatment is specifically beneficial for precision parts where dimensional stability is paramount, including precision tooling and complex mechanical assemblies in aerospace and precision machinery sectors.

Overall Impact on Aluminum Die Casting Properties

Annealing primarily improves plasticity and reduces internal stress without significantly altering strength, making it essential for enhancing formability and stability.

Solution Treatment markedly increases aluminum die castings' strength and corrosion resistance, setting a solid foundation for further property enhancements through aging.

Aging Treatment elevates the yield and tensile strength to higher levels, significantly boosting the material's hardness and wear resistance, making it crucial for high-stress applications.

Hot and Cold Cycle Treatment enhances dimensional stability and stress relief, ensuring precision parts maintain their shape and functionality over time, which is critical for high-accuracy applications.

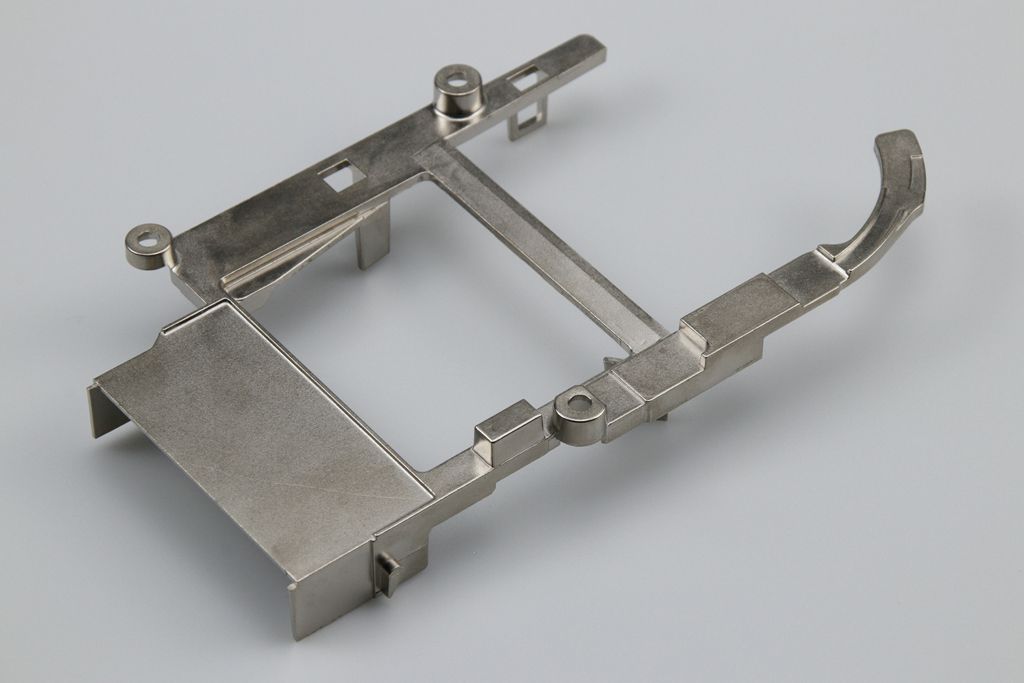

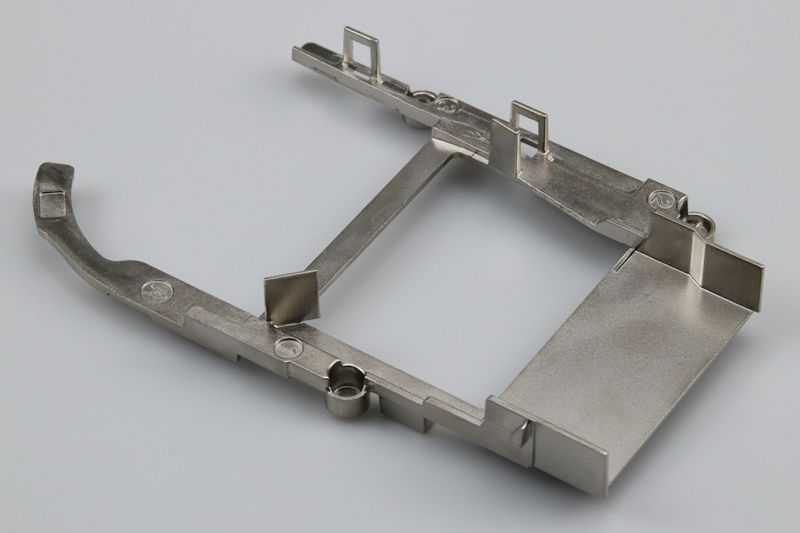

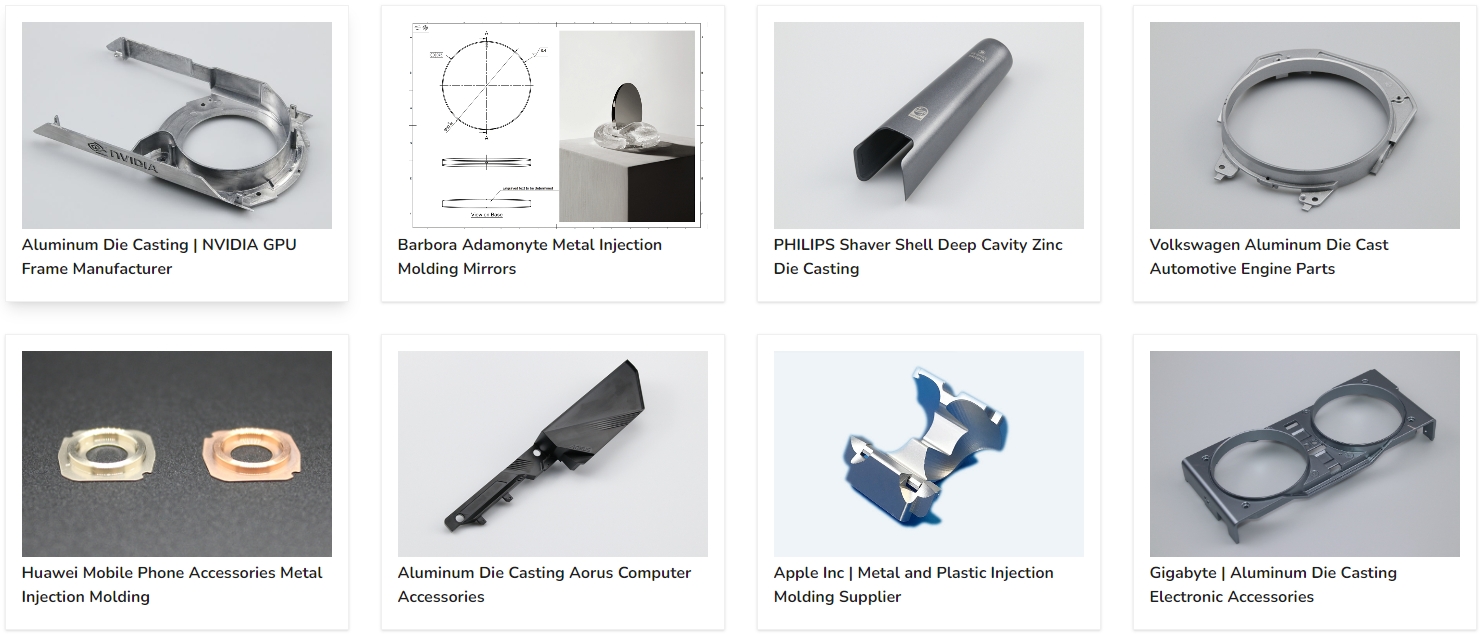

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.

评论

发表评论