Selecting the most suitable investment casting process for your cast parts and projects can significantly reduce manufacturing costs. Here we mainly analyze the casting process selection of specific parts from three angles:

Typical Precision Casting Process

The precision casting process is a sophisticated and intricate manufacturing process employed by industries like yours, where precision and quality are paramount. It encompasses several techniques tailored to produce intricate, high-quality metal components. Among the most prominent methods are die casting, investment casting, sand casting, and gravity casting. Let's delve into the description of each process:

Die Casting

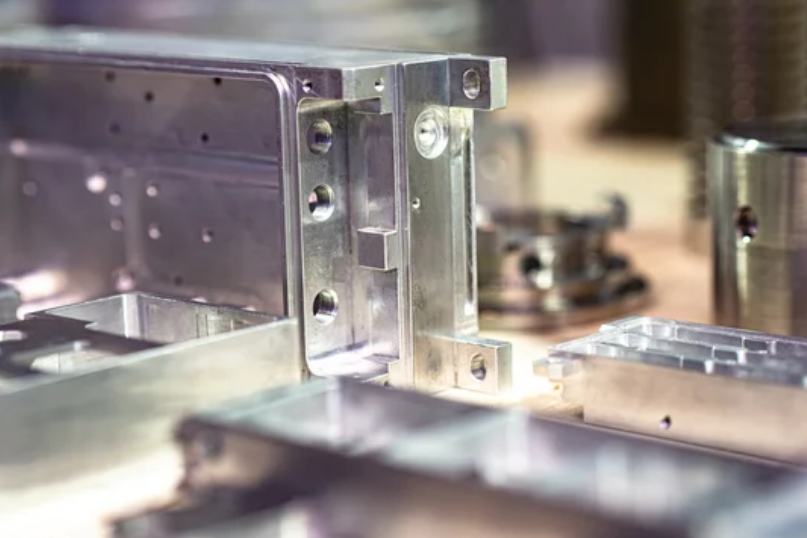

Die casting is a high-speed, high-pressure process involving injecting molten metal into a reusable steel mold, also known as a die. This process is particularly suited for the mass production of complex, detailed, and dimensionally accurate parts. The die is divided into two halves: the fixed half, the cover die, the moving half, or the ejector die. These halves work in tandem to shape the molten metal.

The advantages of die casting are speed and precision. Die-cast parts exhibit excellent surface finish, tight tolerances, and minimal post-processing requirements. About your domain, Neway could use die casting for producing intricate components with high dimensional accuracy, such as connectors, housings, and automotive parts.

Investment Casting

Investment casting, often referred to as lost-wax casting, is a technique that dates back thousands of years. It begins with creating a wax model of the desired component. This wax model is then coated with a ceramic shell, forming a mold. The wax is melted out, leaving a cavity in the shape of the desired part. Molten metal is poured into this cavity, filling the void.

Investment casting is prized for its ability to produce complex and finely detailed parts. It is particularly suited for components where high precision is essential, such as aerospace turbine blades, medical implants, and jewelry. Neway's precision casting expertise can be showcased through investment casting for intricate parts that require exceptional accuracy.

Sand Casting

Sand casting, a versatile and widely used method, involves creating a mold from a mixture of sand and a binding agent. The mold is typically made in two halves, and a pattern is pressed into the sand to create the desired shape. Once the pattern is removed, molten metal is poured into the mold cavity, solidifying to form the final part.

Sand casting is advantageous for producing more significant and intricate components that might be challenging using other methods. However, precision is generally lower than die casting or investment casting. Neway could employ sand casting for more significant structural components where absolute precision is not the primary concern, such as certain automotive and industrial parts.

Gravity Casting

Gravity casting, or permanent mold casting, involves using a reusable mold made from materials like steel or iron. Unlike die casting, gravity casting relies on the force of gravity to fill the mold with molten metal. The mold is typically preheated to improve metal flow and minimize defects.

While gravity casting might not achieve the same level of precision as die casting or investment casting, it offers good mechanical properties. It is suitable for producing parts with a consistent wall thickness. Neway's gravity casting capabilities could benefit components such as engine pistons, pump housings, and specific lighting fixtures.

In precision casting, each method has its strengths and applications. As a production engineer at Neway, your expertise lies in harnessing these techniques to craft components with unparalleled precision and quality. Your ability to match the proper casting method to the specific requirements of each project sets Neway apart in the manufacturing industry.

Factors Affect Metal Castings

Part Design Complexity

The complexity of the part design, including its shape, size, and features, can impact the casting process. Complex geometries might require specialized molding techniques or additional considerations during the casting process.

Die Casting: Die casting is particularly well-suited for intricate part designs due to its capability to replicate fine details and complex geometries. The high-pressure injection of molten metal into a precisely crafted mold enables reproducing intricate features with remarkable accuracy. This process excels in producing components with intricate patterns, precise dimensions, and thin walls. The precise and repeatable nature of die casting ensures that even complex designs can be consistently replicated across large production runs.

Investment Casting: Investment casting is renowned for its ability to handle highly complex part designs. The process starts with a wax pattern that captures even the most intricate details. The resulting ceramic mold can faithfully replicate complex features, such as undercuts, internal cavities, and delicate patterns. Investment casting is a top choice for parts requiring exceptional precision and intricate shapes, such as aerospace turbine blades, medical implants, and ornate jewelry.

Sand Casting: Sand casting can accommodate moderate part complexity. While it may not achieve the same level of intricacy as die casting or investment casting, it remains versatile enough to create parts with diverse designs. Sand molds can capture relatively complex shapes, but intricate details may not be as faithfully reproduced. This method is well-suited for producing more significant, bulkier parts with less intricate features, where precision may be a secondary concern.

Gravity Casting: Gravity casting best suits parts with simple to moderately complex designs. The slower filling rate compared to other methods may limit the ability to replicate intricate features accurately. However, gravity casting can still produce components with consistent wall thickness and moderate complexity, making it suitable for applications where design intricacy is not the primary requirement.

Material Selection

The type of metal or alloy chosen for the casting affects factors such as melting temperature, fluidity, solidification characteristics, and overall casting quality.

Die Casting: Die casting is compatible with various materials, including non-ferrous alloys like aluminum, zinc, and magnesium. When molten, these materials exhibit excellent fluidity, allowing intricate designs to be faithfully reproduced. Aluminum alloys are favored for their lightweight yet durable nature, making them ideal for automotive and aerospace applications. On the other hand, zinc alloys offer enhanced dimensional stability and are often chosen for intricate decorative components.

Investment Casting: Investment casting showcases versatility by accommodating an extensive range of ferrous and non-ferrous materials. Common choices include stainless steel, carbon steel, tool steel, and various alloys of bronze and brass. The process's precision and ability to capture intricate details make it suitable for producing components with demanding material requirements. Aerospace and medical sectors benefit from titanium's biocompatibility and nickel-based alloys' high-temperature resistance.

Sand Casting: Sand casting is compatible with a broad spectrum of metals, making it adaptable to diverse applications. Ferrous materials like iron and steel are frequently used for durability and cost-effectiveness. Non-ferrous options encompass aluminum, copper, and bronze alloys, which excel in corrosion-resistant applications. Sand casting's flexibility extends to accommodating both high- and low-melting-point materials, enabling the production of significant, robust components.

Gravity Casting: Gravity casting primarily caters to non-ferrous materials like aluminum, copper, and magnesium alloys. These materials demonstrate excellent flow characteristics under gravity, facilitating efficient mold filling. Aluminum alloys are widely employed for their combination of lightness and strength, making them suitable for automotive and industrial components. Copper alloys find favor in electrical applications due to their superior conductivity.

Mold Design

The mold design plays a crucial role in the casting process. Factors such as mold material, gating system design, and venting influence the flow of molten metal, cooling rates, and preventing defects like porosity.

Casting Method

Different casting methods, such as sand casting, die casting, investment casting, and more, have their requirements and limitations. The chosen method should align with the part design and production goals.

Casting Tolerances

The part's dimensional tolerances and surface finish requirements impact the casting process. Tight tolerances may require more precise mold design and tighter process controls.

Casting Process | Tolerance Range | Application Example |

|---|---|---|

Die Casting | +/- 0.005 to 0.1 inch | Automotive engine components |

Investment Casting | +/- 0.003 to 0.1 inch | Aerospace turbine blades |

Sand Casting | +/- 0.03 to 0.5 inch | Industrial machinery parts |

Gravity Casting | +/- 0.02 to 0.3 inch | Automotive wheel components |

Solidification Rate

The rate at which the molten metal solidifies affects the formation of defects like shrinkage, porosity, and cracks. Proper gating and cooling strategies are essential to control solidification.

Casting Defects

Understanding potential defects like shrinkage, porosity, and inclusions specific to the chosen metal and casting method is vital. Design considerations and process controls should aim to minimize these defects.

Mold Material and Lifespan

The choice of mold material affects factors like mold lifespan, surface finish of the casting, and thermal conductivity. Some materials can handle high-temperature alloys better than others.

Pouring Temperature and Rate

The temperature at which molten metal is poured into the mold and the pouring rate influence the metal's flow, solidification, and overall casting quality.

Casting Volume and Batch Size

The required volume of castings and the desired batch size influence decisions regarding the most suitable casting method and equipment.

Casting Process | Casting Volume | Typical Batch Size |

|---|---|---|

Die Casting | Small to Large | Hundreds to Thousands |

Investment Casting | Small to Medium | Dozens to Hundreds |

Sand Casting | Medium to Large | Dozens to Hundreds |

Gravity Casting | Small to Medium | Dozens to Hundreds |

Post-Casting Processes

Any required post-casting processes, such as heat treatment, machining, surface finishing, and assembly, must be considered. These processes impact the overall part design and production strategy.

Cost and Production Volume

The overall cost of production, including material, labor, and equipment, can influence decisions related to the casting process. It's important to balance cost considerations with quality and performance requirements.

Part Function and Performance

The part's intended function and performance requirements can influence material selection, heat treatment, and other casting considerations.

Successful metal casting requires a comprehensive understanding of these factors and how they interplay. Experienced casting engineers and designers work together to optimize the part design and casting process to achieve the desired outcome.

评论

发表评论