Powder metallurgy is a versatile manufacturing process that involves the production of parts and components using powdered metal or non-metal materials (ceramic or composite). It offers unique advantages over traditional manufacturing methods, making it a preferred choice for various industries. This article will delve into the process, materials used, and applications of powder metallurgy, highlighting its significance for purchasing and parts design engineers.

Definition and classifications

Powder metallurgy can be defined as a manufacturing technique that involves the production of parts and components from metal or non-metal powders. It encompasses various processes, such as powder compression molding (PCM) service and metal injection moulding (MIM) service. These processes allow for the production of complex and intricate shapes that are difficult to achieve through conventional manufacturing methods.

Powder Compression Molding

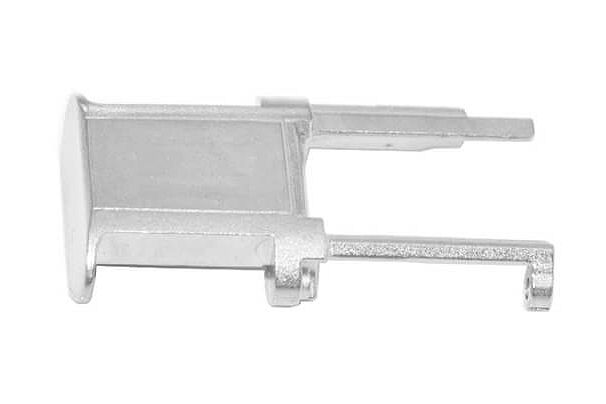

Powder Compression Molding (PCM) involves compacting the powdered material into a desired shape using a die. The powder is typically compressed under high pressure, creating a green compact that retains its shape until further processing.

Due to the relatively simple structure of the pressing die, it cannot produce more complicated parts. Still, it can produce high melting point alloys, hard alloys, and unique metals, such as tungsten, titanium, aluminum, etc.

Metal Injection Molding

Metal injection molding (MIM) combines the principles of powder metallurgy and plastic injection molding. It involves mixing fine metal powders with a binder material to form a feedstock injected into an injection mold. The part is subsequently debinded and sintered to achieve the final desired shape.

A metal injection molding mold is an injection mold, which means that the metal injection molding process is capable of producing extremely complex metal parts.

Advantages over traditional manufacturing methods

Powder metallurgy offers several advantages over traditional manufacturing methods, making it a preferred choice for many applications. Some of the key advantages include:

Cost-Effectiveness: Powder metallurgy facilitates efficient material utilization since it minimizes manufacturing waste. The powder metallurgy material utilization rate is as high as 98% (die casting, investment casting, sand casting, etc., are about 90%-95%, and the material utilization rate of CNC machining is lower). Additionally, it eliminates the need for extensive machining, reducing overall production costs.

Design Flexibility: The process enables the production of complex and intricate shapes that are otherwise challenging or impossible to achieve through conventional manufacturing methods. This design flexibility opens up new possibilities for engineers and designers.

Material Versatility: Powder metallurgy offers various material options, including metal and non-metal powders, such as ceramic injection molding(CIM). Its versatility allows for developing parts with tailored properties, such as enhanced strength, wear, and heat resistance.

Powder Metallurgy Process

Powder metallurgy usually refers to powder compression molding. The powder metallurgy process involves several stages, such as powder preparation, mixing, pressing, sintering, etc., each contributing to the final production of high-quality parts and components.

Powder production

Powder production is a crucial step in the powder metallurgy process. The quality and characteristics of the powder directly impact the final product's properties. Various methods produce metal powders, including atomization, chemical reduction, and mechanical comminution.

Atomization: Atomization is a commonly used method for producing fine metal powders. It involves the rapid solidification of molten metal by subjecting it to a high-pressure gas stream or by using centrifugal forces. The resulting powder consists of spherical particles with excellent flowability and uniform properties.

Chemical Reduction: Chemical reduction methods produce metal powders by reducing metal oxides or salts. These methods involve the introduction of a reducing agent, such as hydrogen or carbon, to the metal oxide or salt at high temperatures. The reduction reaction leads to the formation of metal powders.

Mechanical Comminution: Mechanical comminution refers to the process of reducing larger metal pieces into fine powders using mechanical forces. Milling, grinding, and crushing achieve the desired particle size distribution.

Powder blending and pressing

Once the metal powder is produced, it is often blended with additives and lubricants to enhance its flowability and facilitate compaction. Powder blending ensures a homogeneous distribution of the additives throughout the powder mixture, resulting in consistent properties in the final product.

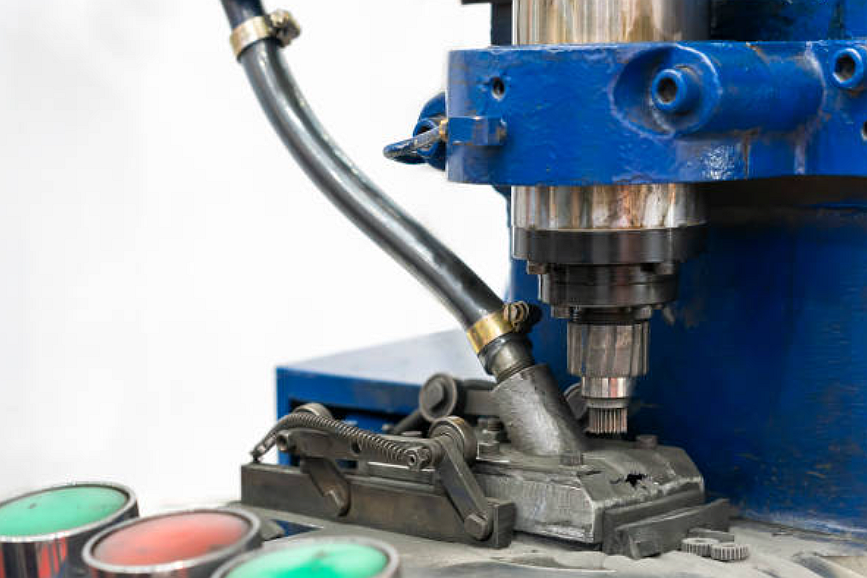

The blended powder mixture is then compacted using hydraulic or mechanical presses to form green compacts. The compaction process involves applying pressure to the powder within a die, consolidating particles, and forming a green compact with the desired shape.

Sintering and densification

Sintering is a critical stage in the powder metallurgy process where the green compacts are subjected to elevated temperatures in a controlled atmosphere. The sintering process involves heating the compacted powder to a temperature below its melting point but high enough to facilitate the bonding of particles. Sintering is usually divided into three methods: vacuum, hot pressing, and pressureless.

Vacuum sintering: Vacuum sintering is employed to strengthen and densify the brown part. The sintering process involves heating the brown part in a vacuum furnace to a temperature below its melting point. The heat causes the metal particles to bond, eliminating the remaining porosity and forming a solid, dense metal part. The vacuum environment is necessary to prevent oxidation and maintain the purity of the metal.

Hot pressing sintering: Hot pressing sintering, also known as hot isostatic pressing (HIP), is a technique used to enhance the properties of powder metallurgy parts by subjecting them to high temperature and pressure. The process begins with complying metal powders into a desired shape using cold or warm compaction methods. The compacted powders are then placed in a sealed container, usually made of metal, called a canister.

The compacted powder canister is placed in a high-temperature furnace or pressurized vessel. The temperature and pressure applied during hot pressing sintering are carefully controlled to ensure optimal densification of the powders. Typically, temperatures range from 900 to 1,400 degrees Celsius (1,650 to 2,550 degrees Fahrenheit), and pressures can range from a few hundred to several thousand atmospheres.

Pressureless sintering: Pressureless sintering is a crucial process in powder metallurgy that involves consolidating powdered metal particles into a solid object without applying external pressure. It is also known as solid-state sintering or diffusion bonding.

The absence of external pressure distinguishes pressureless sintering from other sintering methods, such as hot isostatic pressing (HIP) or cold isostatic pressing (CIP), which utilize applied pressure during the sintering process. Pressureless sintering is commonly used for materials with lower sintering temperatures or when complex shapes or thin-walled components are involved.

During sintering, the metal particles undergo diffusion, leading to the formation of necks between adjacent particles. This bonding mechanism produces densification and a solid structure with improved mechanical properties.

Additional processes (optional)

In addition to powder blending, compaction, and sintering, other optional processes can be employed in powder metallurgy to achieve specific properties or geometries. These processes include:

Heat treatment: Heat treatment is often used after sintering to enhance the properties of the finished parts further. It involves subjecting the sintered parts to controlled heating and cooling cycles to modify their microstructure and achieve desired material properties.

Infiltration: Infiltration is a process where molten metal is introduced into the porous structure of a sintered part to enhance its strength and density. This technique is commonly employed to improve the performance of parts in applications that require high mechanical strength.

Materials Used in Powder Metallurgy

Metal powders are the primary materials used in powder metallurgy. They can be produced from various metals, including steel, iron, aluminum, copper, and alloys. The properties of the metal powders, such as particle size, morphology, and chemical composition, play a crucial role in determining the characteristics of the final product.

MIM metal Powder

Steel powder is widely used in powder metallurgy due to its excellent mechanical properties and versatility. It can be alloyed with other elements to achieve specific characteristics, such as increased strength, improved corrosion resistance, and enhanced wear resistance. The following are common MIM metal powders and grades.

Common MIM metal Powders and Grades:

MIM ceramic powders

In addition to metal powders, non-metal powders are also utilized in powder metallurgy. These include ceramics, polymers, and composite materials. Non-metal powders offer unique properties, such as high-temperature resistance, electrical insulation, and lightweight characteristics, expanding the range of applications for powder metallurgy. The following are standard MIM ceramic powders and their grades:

Common MIM Ceramic Powders and Grades:

Alumina (Al2O3): Alumina is one of CIM's most widely used ceramic materials. It exhibits exceptional mechanical strength, excellent electrical insulation properties, and high thermal conductivity. Alumina ceramic parts find applications in the automotive, electronics, and medical industries.

Zirconia (ZrO2): Zirconia ceramics offer outstanding mechanical properties, including high strength, toughness, and wear resistance. They also exhibit low thermal conductivity and excellent corrosion resistance. Zirconia-based ceramic parts are utilized in demanding applications, such as cutting tools, biomedical implants, and components for extreme environments.

Silicon Nitride (Si3N4): Silicon nitride ceramics combine high strength, excellent thermal shock resistance, and low density. They possess exceptional wear and corrosion resistance, making them suitable for automotive, aerospace, and chemical processing applications.

Alloying and additives

Alloying is a common practice in powder metallurgy, where different metal powders are blended to create alloys with tailored properties. By combining powders of different metals, engineers can achieve specific characteristics such as increased strength, improved hardness, and enhanced heat resistance.

Neway's MIM material engineers can customize metal powders to meet customers' needs according to their special product requirements. These include developing special tungsten alloy powder for armor-piercing projectile testing, high-temperature resistant powder for high-voltage electric shock, etc.

Applications of Powder Metallurgy

Powder metallurgy finds widespread applications in various industries due to its unique advantages and versatility. Some of the key industries where powder metallurgy plays a crucial role include:

Automotive industry

The automotive industry extensively utilizes powder metallurgy to produce engine components, transmission parts, bearings, and gears. Powder metallurgy allows for the manufacturing high-strength and lightweight parts, resulting in improved fuel efficiency and reduced emissions.

Aerospace industry

In aerospace, powder metallurgy produces critical components such as turbine blades, heat exchangers, and structural parts. The high strength-to-weight ratio achieved through powder metallurgy makes it ideal for aerospace applications where weight reduction is essential for fuel efficiency and performance.

Medical equipment

Powder metallurgy is vital in the medical equipment industry, where it manufactures surgical instruments, orthopedic implants, and dental components. The biocompatibility of powder metallurgy materials and their excellent mechanical properties make them suitable for use in the human body.

Consumer goods and more

Powder metallurgy produces consumer goods such as power tools, sporting equipment, and appliances. Additionally, it finds applications in industries such as electronics, defense, energy, and telecommunications, where complex geometries and specific material properties are required.

Advancements and Future Trends in Powder Metallurgy

Powder metallurgy continues to evolve, with ongoing advancements and emerging trends shaping the future of the field. Some critical areas of development include:

New materials and alloys

Researchers and engineers constantly explore new materials and alloys for powder metallurgy applications. Developing novel metal and non-metal powders and incorporating nanostructured materials can unlock enhanced properties and performance in the final products.

Improved manufacturing techniques

Advancements in manufacturing techniques, such as additive manufacturing or 3D printing using metal powders, are revolutionizing the powder metallurgy industry. These techniques offer greater design freedom, reduced material waste, and the ability to produce highly complex parts with intricate internal structures.

Emerging applications

As powder metallurgy capabilities expand, new and emerging applications are being explored. For example, the use of powder metallurgy in the production of biomedical implants with tailored surface properties for enhanced osseointegration is gaining attention. Similarly, developing lightweight and high-strength parts for the electric vehicle industry is another promising avenue for powder metallurgy.

Conclusion

In conclusion, powder metallurgy is a versatile manufacturing process that offers numerous advantages over traditional manufacturing methods. It allows for producing complex and high-performance parts with tailored material properties. With its wide range of applications in automotive, aerospace, medical equipment, and other industries, powder metallurgy has become a critical technology for purchasing and parts design engineers.

By understanding the powder metallurgy process, materials used, and its diverse applications, engineers and designers can leverage the unique benefits of powder metallurgy to create innovative and efficient solutions for their specific needs.

Remember, Neway can meet your requirements whether you require sintered filters, metals, or steel powders. Embrace the advantages of powder metallurgy and unlock new possibilities for your projects and designs. Start New Projects Today

评论

发表评论