Metal parts manufacturing is crucial in various industries, from automotive and aerospace to electronics and medical. Two popular methods for producing custom metal parts are Metal Injection Molding (MIM) and Die Casting. In this article, we will explore these processes, their advantages, limitations, suitable applications, and materials and compare them to help you decide when choosing the right process for your custom metal parts.

Metal Injection Molding (MIM)

Metal Injection Molding (MIM) is a manufacturing process that combines the benefits of plastic injection molding and powder metallurgy. It involves the production of complex metal parts using fine metal powders and a binder material. The process includes several steps, such as feedstock preparation, injection molding, debinding, and sintering. MIM offers excellent design flexibility, allowing the production of intricate and highly precise metal components.

Advantages and Limitations of MIM

MIM offers numerous advantages, including the ability to manufacture complex geometries, high production efficiency, excellent surface finish, and tight tolerances. It also enables using a wide range of MIM materials, such as stainless steel, titanium, and even magnetic alloys. However, MIM does have limitations, such as higher tooling costs, longer production cycles, and limitations in the size of parts that can be produced.

Applications and Suitable Materials for MIM

MIM finds applications in various industries, including medical devices, electronics, automotive, and aerospace. It is ideal for producing small to medium-sized complex metal parts, such as surgical instruments, firearm components, and electronic connectors. The suitable materials for MIM include stainless steel, low-alloy steel, tool steel, and other specialty alloys.

MIM Process | Die Casting | ||

Complexity | High | High | |

MIM Materials | Multiple such as stainless steel, Aluminum Alloy, Titanium Alloy, Tungsten Alloy, Copper Alloy | Die Casting Materials | Mainly Aluminum alloy, Zinc alloy, Magnesium alloy,Brass alloys |

Material Type | Metal Powders | Material Type | Metal ingot |

MIM Parts Size | small: The projected area does not exceed 10x10 inches (250mmx250mm) | Die Casting Parts Size | Small or mid: The projected area does not exceed 30x30 inches(750mmx750mm). Special large-scale equipment is able to produce larger parts. |

MIM Toletance | 1~2 % | Die Casting Tolerance | 2~3% |

Die Casting

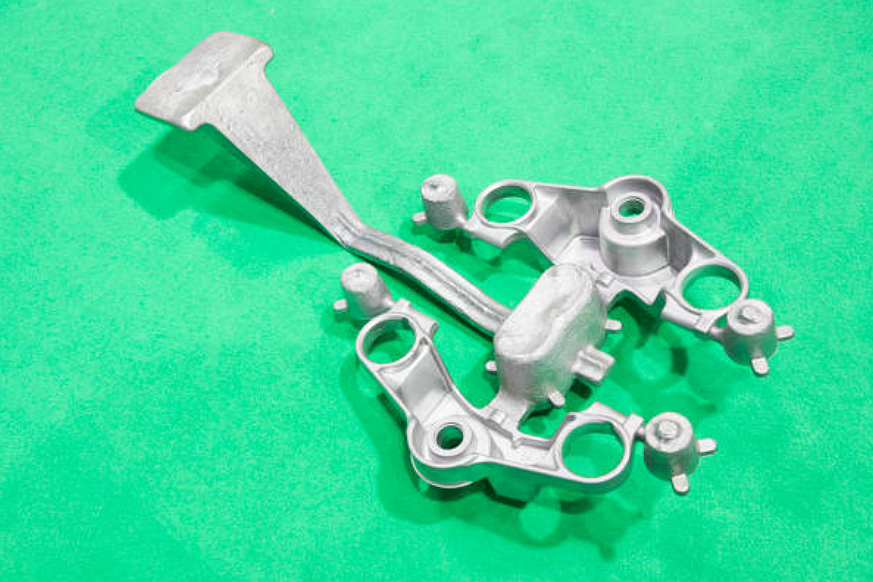

Die casting is a widely used manufacturing process for producing metal parts with excellent dimensional accuracy and surface finish. It involves injecting molten metal into a reusable mold, known as a die, under high pressure. Once the metal solidifies, the mold is opened, and the part is ejected. Die casting is known for its efficiency and the ability to produce high volumes of parts with consistent quality.

Advantages and Limitations of Die Casting

Die casting offers several advantages, including high production speed, excellent dimensional stability, and the ability to produce intricate parts with thin walls. It also provides a good surface finish and dimensional accuracy. However, die casting has limitations, such as higher initial tooling costs, limited material options compared to MIM, and less design flexibility for complex geometries.

Applications and Suitable Materials for Die Casting

Die casting is widely used in industries such as automotive, aerospace, consumer electronics, and appliances. It is suitable for producing medium to large-sized parts, such as engine components, housing for electronic devices, and structural parts. Common materials used in die casting include aluminum, zinc, magnesium, and copper alloys.

Comparison of MIM and Die Casting

Cost Considerations

When it comes to cost considerations, die casting generally has lower tooling costs compared to MIM. However, MIM can offer cost advantages for complex parts requiring multiple die-casting components. The production cost depends on factors such as part complexity, material selection, and required volumes.

How to Calculate MIM Cost

The material utilization rate of powder metallurgy parts is generally 95%-98%. The raw material cost of a metal part is roughly calculated as follows:

MIM Parts Material cost

(Cost per gram of metal material x part volume x part density) / 95%

The material cost should also include the actual cost of raw materials, such as lubricants and alloying element additives.

Injection Mold cost

The cost of the mold includes the price of the mold plus the cost of maintenance and replacement. The original price of the mold depends on the complexity of the mold, which is directly related to the part's complexity. Therefore, the cost should be related to the complexity of the part. Since a set of powder metallurgy molds often produces a large number of parts, the mold material should be a material that can withstand high pressure and powder friction.

Cost suppression

Containment costs include machine costs and labor costs. As the tonnage of the press increases, the investment cost of the press increases, but the productivity decreases. The selection of the press size is based on the product of the cross-sectional area perpendicular to the compaction direction and the unit compaction pressure. The unit pressing pressure is related to the pressing density of the part. The unit pressing pressure of low-density iron base parts is generally 400MPa, and the medium-high density is 600-700mpa. Printing costs are also related to printing automation and printing rates. Although the duty cycle of powder metallurgy presses is slower than stamping parts, it is faster than plastic molding presses and requires less equipment.

Sintering cost

The sintering cost includes equipment cost, energy consumption, shielding gas, and labor costs. Due to the different sintering processes, fusion costs also include fusion costs (additional costs such as pressing and placing of fused metals). Since sintering does not require heating the base metal to its melting point, it consumes less energy than the casting process.

Subsequent processing cost

The cost of subsequent processing includes the cost of all possible subsequent processing processes, such as finishing, dipping, small metal cutting, heat treatment, or surface treatment (steam treatment, grinding, deburring, shot blasting, etc.).

In addition to direct production costs, production costs should include management and auxiliary costs. Management costs include major items such as design, technology, and sales, and auxiliary costs include power management, equipment maintenance, and transportation. Generally speaking, these expenses can be calculated according to the proportion of the long-term accumulated data in the above-mentioned direct expenses to the direct expenses of production.

How to Calculate Die Casting Cost

The material utilization rate of die casting parts is generally 90%-95%. The raw material cost of a metal part is roughly calculated as follows:

Die Casting Parts Material cost

(Cost per gram of metal material x part volume+x part density)/90%

The material cost should also include the actual cost of raw materials, such as alloying element additives.

Mold cost

MIM's mold is an injection mold, and its complexity and precision will be higher than a die-casting mold. The general mold cost is 2.5 times the mold material cost for simple die-casting molds with no rows.

Die Casting Cost

The cost of die-casting is more straightforward than that of MIM. The cost of opening and closing the mold is calculated according to the tonnage of the die-casting machine and the time to produce one product. Rough estimates can also be made, such as 0.8USD/UNITS per month for a 300-ton die-casting machine

Post-processing cost

The cost of subsequent processing includes the cost of all possible subsequent processing processes, such as finishing, dipping, small metal cutting, heat treatment or surface treatment (steam treatment, grinding, deburring, shot blasting, etc.).

Conclusion

Choosing the right manufacturing process for custom metal parts is crucial for achieving the desired quality, cost-effectiveness, and design flexibility. Metal Injection Molding (MIM) and Die Casting are widely used processes, each with advantages and limitations. MIM excels in producing complex geometries with a wide range of materials, while die casting offers high production efficiency and excellent dimensional accuracy for larger parts. By considering cost, design requirements, material properties, and production volume, you can decide when to select the most suitable process for your custom metal parts.

MIM and die casting are valuable manufacturing processes catering to different requirements. Assessing your specific needs and collaborating with experienced metallurgy companies and die cast companies will ensure that you achieve optimal results for your custom metal parts projects.

If you are seeking a reliable custom metal and plastic parts manufacturer, contact us to discuss your project's specific requirements and ensure the best possible outcomes.

评论

发表评论