Metal injection molding (MIM) service has become attractive for producing complex, net-shape aerospace components with tight tolerances. MIM combines the versatility of plastic injection molding with the whole material properties of sintered metals. Fine metal powder mixed with a polymer binder can be injection molded into various geometries. After binder removal and high-temperature sintering, the final parts retain their molded shape with excellent mechanical properties.

Our company specializes in providing full-scale MIM services from design to finished components. With extensive aerospace engineering experience, we offer rapid prototyping of new designs and scalable production of existing parts. Our capabilities include:

Complex multi-cavity mold design.

Feedstock formulation.

Precision high-volume molding.

Automated debinding and sintering.

Final machining.

We work with proven aerospace alloys like titanium, nickel, stainless steel, and cobalt chrome. Contact us today to discuss how MIM can improve the manufacturing and performance of your aerospace parts!

Commonly aviation MIM Metals

In aviation, Metal Injection Molding (MIM) finds application with various metals and alloys prized for their exceptional properties.

Stainless steel 316L is chosen for its corrosion resistance and biocompatibility, making it ideal for aerospace components.

Titanium alloys like Ti-6Al-4V offer high strength and low density, suitable for structural and engine parts.

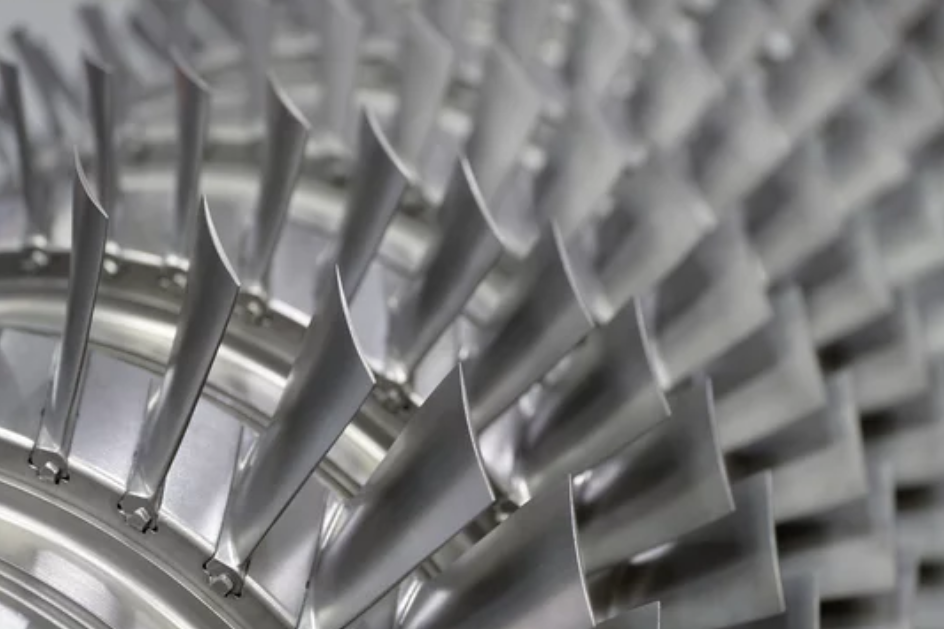

Cobalt-chromium alloys excel in wear resistance and high-temperature performance, often used in turbine components.

Nickel-based alloys like Inconel and Hastelloy thrive in extreme environments, valuable for aerospace applications.

While aluminum and magnesium alloys are less common in MIM, they offer lightweight solutions for specific aerospace needs.

Why MIM Parts Suit for Aerospace Components

Metal injection molding (MIM) offers several distinct advantages, making it an ideal process for manufacturing intricate aerospace components. MIM can produce complex, net-shape metal parts with tight tolerances, fine details, and excellent mechanical properties. The process starts with a feedstock of fine metal powder and binder that can be molded into complex shapes. First, the binder is removed from the green part during debinding. Then, high-temperature sintering densifies the metal powder to near full density while retaining the molded shape. The result is a seamless, near-net-shaped metallic component. MIM rivals casting and machining for small complex parts at a lower cost and with less material waste.

Additionally, MIM enables the use of advanced alloys, including difficult-to-machine metals like titanium, Inconel, tool steel etc. Parts benefit from the inherent material strengths and operating capabilities. By combining the design freedom of plastic injection molding and the wide alloy selection of powder metallurgy, MIM can produce intricate, high-performance metal components to meet the critical demands of aerospace service. The process is highly repeatable and well-suited for automated mass production. These capabilities make MIM an exceptional manufacturing solution for small, complex aerospace hardware.

Aerospace MIM Parts Mold Design

Molds for aerospace MIM components must deliver tight dimensional tolerances. The cavities should be capable of producing parts with tolerances of ±0.1% or better to achieve components like turbine blades with precise airfoil shapes. Fine surface finishes are also required, typically with Ra between 0.1-0.4 μm. Highly polished mold surfaces help minimize post-molding finish machining.

Complex geometries with conformal cooling channels allow MIM to manufacture intricate parts not feasible by other methods. Design features like thin walls, small holes, and fine details are possible. Gate design and location should promote uniform cavity filling to avoid defects. Adequate draft angles on vertical surfaces, typically above 1°, are necessary to ensure easy part ejection and avoid cracking.

Robust tool steel molds that can withstand high pressures and temperatures over thousands of cycles are required for consistency, dimensional accuracy, and mold longevity when producing precision aerospace components via metal injection molding.

Consultative Design Services

Neway custom metal injection molding service provides free Consultative Design Services throughout the process. This includes all processes from your design stage to mass-produced finished products.

1. Material selection Consult

2. Structural design service

3. Mold design service

Contact us now if you are interested.

What We Can Do in Aerospace MIM?

We offer free material selection and consultative design services from Begin to end. No MOQs, Rapid prototyping, and mass production are our strengths.

Structural design service

Mold design service

Feasibility testing

QCS-Quick Cargo Service GmbH was having issues with porosity and dimensional consistency in their titanium turbine blades produced externally. By switching to Neway's MIM process, they reduced defects and machining while boosting mechanical properties. Neway's engineering enhancements also improved blade longevity by over 20%. QCS's sourcing manager said, "Neway's metal injection molding and tight process controls result in our most reliable titanium components yet."

评论

发表评论