Metal Injection Molding Automotive Cam Mechanism: MIM Supplier

Cam mechanisms are ingenious devices that transform rotary motion into reciprocating or oscillating motion. They consist of a cam, which is a specially shaped profile, and a follower, typically a lever or a roller, that follows the contour of the cam.

In the production world, cam mechanisms find their application in many contexts. For instance, in Consumer Electronics, cam mechanisms are utilized in compact disc trays to smoothly open and close. The precision of these mechanisms ensures a seamless user experience. In the Telecommunication industry, cam mechanisms are pivotal in creating precise movements in devices like switches and connectors. In Power Tools, cam mechanisms drive the reciprocating action of saws and drills, enhancing their efficiency and accuracy. In the Lighting Solutions sector, they control the positioning of light fixtures, enabling precise illumination control. Finally, in Locking Systems, cam mechanisms are integral to secure doors and cabinets, ensuring safety and ease of use.

Cam mechanisms are intricate mechanical devices vital in various industries, including the automotive sector. These mechanisms operate on a simple yet ingenious principle, wherein a cam, typically a specially shaped profile, interacts with a follower, such as a lever or roller, to transform rotary motion into reciprocating or oscillating motion.

In the automotive industry, cam mechanisms are employed in several key areas. For instance, in the valve train of an internal combustion engine, camshafts with carefully designed cam profiles control the opening and closing of the intake and exhaust valves. These valves' precise timing and lift are crucial for optimizing engine performance, fuel efficiency, and emissions control. Moreover, in transmission systems, cam mechanisms facilitate gear shifting by controlling the engagement and disengagement of gears, ensuring smooth and reliable transitions. This precision is fundamental in providing a comfortable and efficient driving experience.

Neway, a production engineering leader, excels in producing cam mechanisms for the automotive industry. Our precision casting and MIM process expertise ensure that cam profiles meet stringent tolerances, enhancing engine performance and longevity. Neway's commitment to excellence makes it a sought-after partner in the automotive sector, where precision and reliability are paramount.

Metal Injection Molding (MIM) in Automotive Industry

Metal injection molding (MIM) is a versatile manufacturing process pivotal in the automotive industry, offering precision and cost-effective solutions. MIM combines the benefits of both plastic injection molding and traditional metalworking, enabling the production of complex, high-precision components. For instance, MIM can achieve remarkable tolerances, down to +/- 0.002 inches, ensuring the reliability and functionality of critical automotive parts.

MIM finds extensive use in crafting intricate components such as gears, bushings, and connectors in the automotive sector. These components demand exceptional precision and material durability, making MIM the perfect choice. For example, in the power tools sub-industry, MIM is instrumental in producing intricate gear mechanisms, where its high precision is crucial for seamless power transmission. This results in quieter, more efficient, and longer-lasting power tools, enhancing user experience.

Moreover, MIM's efficiency shines in the production of locking system components, where intricately designed key and lock parts require precision beyond conventional machining capabilities. MIM meets these stringent requirements and offers cost advantages by reducing material waste and machining time. Hence, MIM's role in the automotive industry is indispensable, optimizing precision and economic efficiency in producing critical components.

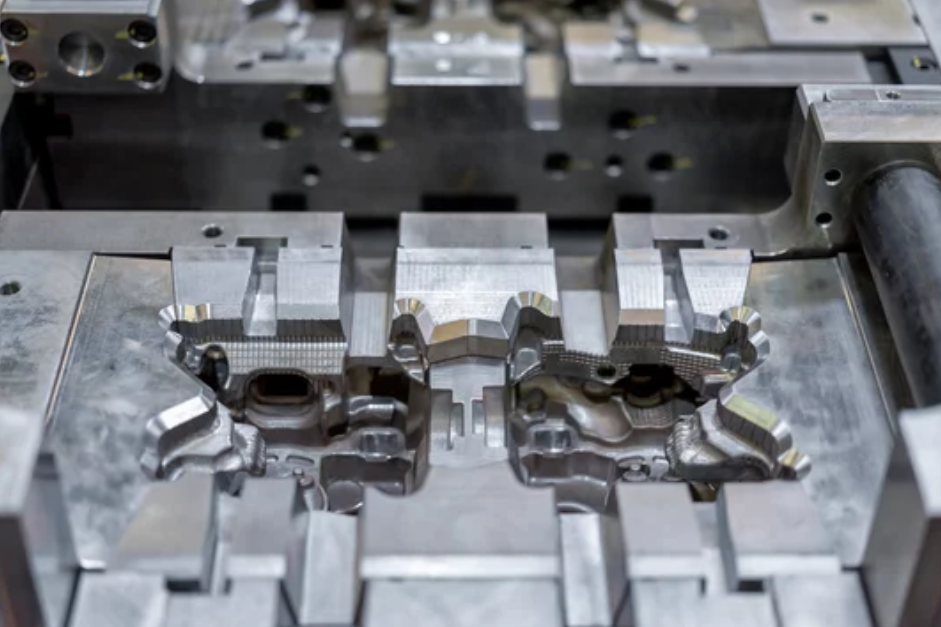

MIM Cam Mechanisms Manufacturing

Cam mechanisms are vital in various industries, including automotive, consumer electronics, and power tools. These mechanisms require high precision with specific values and requirements for optimal performance. In the automotive industry, camshafts, for instance, are crucial for controlling valve timing and engine performance. The precision requirement for camshaft lobes typically ranges from 0.0001 to 0.001 inches, ensuring precise timing of valve opening and closing.

In consumer electronics, cam mechanisms are employed in compact devices like smartphones for camera zoom and focus adjustments. Here, precision is paramount, with tolerances as tight as 0.00004 inches to achieve smooth and accurate movements. This level of precision enhances user experience by delivering sharp and clear images.

Power tools also heavily rely on cam mechanisms for controlling various functions, such as the rotation of drill bits. Precision values commonly range from 0.0001 to 0.0002 inches for these applications, ensuring reliable and consistent tool performance. In this context, MIM (Metal Injection Molding) can be a valuable manufacturing method, as it allows for the production of intricate cam components with the high precision required while minimizing material waste and machining time, ultimately leading to more cost-effective manufacturing.

MIM Vs. CNC Machining

Metal Injection Molding (MIM) and CNC machining are two distinct manufacturing processes, each with unique advantages. When crafting a cam mechanism, MIM offers several critical advantages over CNC machining.

First and foremost, MIM excels in producing intricate and complex cam mechanisms with high precision. This process allows for creating components with tolerances as tight as +/- 0.002 inches, ensuring the cam's profile and features are precisely replicated. In contrast, CNC machining may face limitations when dealing with intricate designs, and achieving the same level of precision may require time-consuming programming and tool changes.

MIM also boasts efficiency in material usage. Traditional CNC machining involves subtractive manufacturing, removing excess material from a solid block. In contrast, MIM is a near-net-shape process, significantly reducing material waste. This efficiency is especially beneficial in producing cam mechanisms, as it helps reduce raw material costs and promotes sustainability.

Furthermore, MIM's capability to produce intricate components with complex geometries, such as cams, in large quantities and with minimal post-processing results in cost savings. For power tools and consumer electronics applications, where precision and cost-effectiveness are paramount, MIM stands out as an excellent choice for crafting cam mechanisms, making it a preferred method over CNC machining.

MIM Vs. Investment Casting

Metal Injection Molding (MIM) and investment casting are valuable manufacturing processes. Still, when producing a cam mechanism, MIM offers several advantages over investment casting, particularly in precision, material selection, and cost-effectiveness.

Precision is paramount in cam mechanisms, and MIM excels in this aspect. MIM can achieve intricate details and tight tolerances, often as precise as ±0.002 inches or even better. While suitable for many applications, investment casting may struggle to match MIM's precision, especially with intricate cam profiles. MIM's high precision ensures that cam mechanisms operate with absolute accuracy, which is crucial in the automotive and consumer electronics industries.

Material selection is another crucial advantage of MIM over investment casting. MIM can use various materials, including metals and alloys, offering greater flexibility in meeting specific performance requirements. In contrast, investment casting may have limitations in material selection, which could be a significant drawback when the cam mechanism needs to meet specific material properties, such as corrosion resistance or high-strength characteristics.

Cost-effectiveness is a decisive factor, particularly in high-volume production. MIM is highly efficient regarding material usage and production time, saving costs. Investment casting, on the other hand, can be more resource-intensive due to the preparation of molds and the subsequent removal of casting material. It can result in higher production costs, making MIM a preferred choice for cost-effective manufacturing of cam mechanisms.

Benefits of MIM Cam Mechanisms

MIM (Metal Injection Molding) cam mechanisms offer various benefits, making them a preferred choice across various industries. These advantages stem from MIM's ability to produce high-precision, intricate components efficiently and cost-effectively.

First and foremost, MIM cam mechanisms excel in precision. They can achieve remarkable tolerances, often as tight as ±0.002 inches or even better. This high precision is essential for cam mechanisms, ensuring their reliable and accurate operation. Whether used in automotive engines, consumer electronics devices, or power tools, MIM cam mechanisms deliver consistent and predictable performance, enhancing product quality and end-user satisfaction.

Cost-effectiveness is another crucial benefit. MIM optimizes material usage, significantly reducing waste compared to traditional machining processes. Additionally, MIM's high production efficiency and shorter cycle times contribute to cost savings, making it an economically attractive option for high-volume cam mechanism production. MIM cam mechanisms provide a competitive edge in industries like automotive and consumer electronics, where cost control is critical.

Lastly, MIM cam mechanisms are versatile and can be customized to meet specific application requirements. The MIM process allows for the use of various materials, offering the flexibility to select metals or alloys with the desired mechanical properties, such as corrosion resistance or high-strength characteristics. This adaptability ensures that MIM cam mechanisms can serve various industries, from automotive and consumer electronics to power tools, effectively meeting these sectors' diverse needs.

MIM Parts Case Study

Tool steel metal injection molded (MIM) parts offer many advantages, mainly when applied to the design of cam mechanisms within the realms of Consumer Electronics, Telecommunication, Lighting Solutions, Power Tools, and Locking Systems. Firstly, the precision attainable through MIM in cam mechanisms is exceptional, with tolerances as tight as a few microns. It is crucial in smartphone cameras, where smooth and precise movements are vital for image stabilization. Such high-precision components improve product performance and longevity, enhancing user experience and satisfaction. These qualities are synonymous with Neway's commitment to delivering top-notch solutions across various industries.

Tool Steel MIM Cam Mechanisms

Additionally, MIM facilitates complex geometries, allowing for the creation of intricate cam designs with unparalleled efficiency. This flexibility is instrumental in the Telecommunication sector, where miniaturization is critical. More minor, highly intricate cams can be manufactured, contributing to the developing of compact and powerful communication devices. Neway's expertise in MIM empowers innovation in this domain, aligning seamlessly with industry demands for sleek and efficient products.

Moreover, the exceptional wear resistance of tool steel, a specialty of Neway's MIM process, ensures that cam mechanisms remain durable and reliable even under heavy usage. It is especially vital in Power Tools, where the longevity of cam-driven components is directly related to the tool's lifespan. Neway's mastery of MIM enables the production of robust, wear-resistant cam mechanisms that endure in demanding environments. In conclusion, tool steel MIM's precision, versatility, and durability make it an ideal choice for cam mechanisms across various industries, underscoring Neway's commitment to excellence and innovation.

Challenges And Solutions

Manufacturing Tool Steel Metal Injection Molding (MIM) Cam Mechanisms present a unique set of challenges, but with innovative solutions, these challenges can be overcome to achieve outstanding results. Here, we will explore the primary challenges and the solutions that favor Neway's expertise in producing high-quality MIM components.

Challenge 1: Material Selection

Tool Steel for MIM Cam Mechanisms is pivotal but poses challenges. Tool Steel materials have specific properties that must be carefully tailored to meet the application's demands. Selecting the suitable Tool Steel alloy can be complex, but Neway's extensive material science and engineering knowledge ensures optimal material selection. An in-depth analysis of application requirements guides the choice of Tool Steel alloy, guaranteeing superior mechanical properties and wear resistance.

Neway's team of experienced engineers excels in material selection, having worked with a range of Tool Steel alloys. They rely on data-driven decisions, conducting thorough material testing and analysis to determine the most suitable alloy. This approach guarantees that Tool Steel MIM Cam Mechanisms are tailored to meet the precise needs of various industries.

Challenge 2: Precision and Tolerance Control

High-precision applications in industries such as Consumer Electronics and Power Tools require Cam Mechanisms with extremely tight tolerances. Achieving such precision in MIM components can be challenging due to the shapes' complexity and the MIM process's inherent nature. Ensuring that each component meets the specified tolerances is crucial.

Neway leverages advanced process control technologies and a checking system to maintain the tightest tolerances in MIM Cam Mechanisms. They employ state-of-the-art equipment and utilize data-driven techniques to monitor and adjust the production process continuously. It ensures that the final components consistently meet the precise specifications, even in applications with micron-level tolerances.

Challenge 3: Post-Processing and Surface Finish

MIM Cam Mechanisms must often have excellent surface finishes to reduce friction and wear. Achieving the desired surface finish can be challenging in MIM due to the powder metallurgy process, which may give parts a rough texture.

Neway employs innovative surface treatment techniques, such as precision polishing and coatings, to enhance the surface finish of MIM Cam Mechanisms. These processes improve aesthetics and contribute to the components' functionality by reducing friction, ensuring smooth operation.

Customer Testimonials

"We partnered with Neway for our Tool Steel MIM Cam Mechanisms, and the results were outstanding. The precision and durability of the components were exactly what we needed for our high-end electronics. Neway's expertise in material selection and their commitment to quality were truly impressive. We've seen a significant improvement in our product's performance, and our customers have noticed, too. It's a pleasure working with a manufacturer who understands our specific needs and consistently delivers top-notch solutions."

- John Lyapushin., Electronics Manufacturer

Neway's Expertise As MIM Supplier

Neway is an industry leader and a trusted partner in Metal Injection Molding (MIM) manufacturing. With a profound commitment to excellence and a strong focus on precision, Neway's expertise as a MIM supplier is unrivaled. We specialize in producing intricate components that are instrumental across various industries, including Consumer Electronics, Telecommunication, and Power Tools.

Our core strength lies in material selection and process optimization. Neway's team of experienced engineers excels in identifying the ideal materials for each application, ensuring the perfect blend of strength, hardness, and wear resistance. This expertise is the foundation of our ability to deliver consistently high-quality MIM components.

Furthermore, Neway's cutting-edge facilities and state-of-the-art equipment enable us to produce complex geometries with micron-level precision. We understand the significance of intricate designs in today's technological landscape, and we can bring even the most challenging concepts to life. Our commitment to quality assurance and in-process monitoring ensures that each component adheres to the strictest industry standards.

Common MIM Materials We Use:

评论

发表评论