Understanding MIM Shrinkage

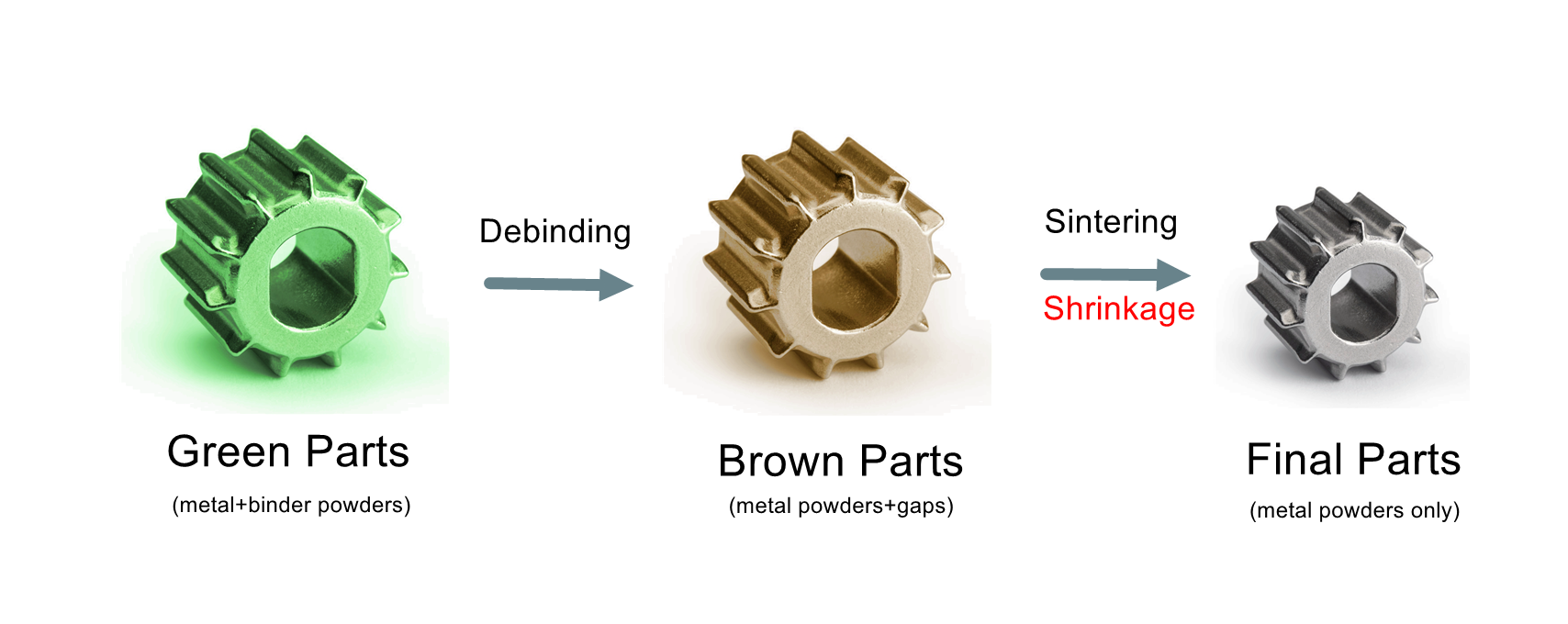

The shrinkage in Metal Injection Molding (MIM) is a critical consideration in the manufacturing process. During MIM, metal powders are mixed with a binder to create a feedstock, which is then molded into the desired shape. After molding, the parts go through a debinding process to remove the binder, and then they are sintered at high temperatures to achieve the final metal part.

Shrinkage in MIM occurs primarily during the sintering phase. During sintering, the metal particles in the feedstock bond together and densify, causing the part to shrink. The shrinkage can vary depending on several factors, including the material used, the specific MIM process parameters, and the part's geometry.

Typically, the shrinkage in MIM falls within the range of 15% to 20%. It means a part initially molded will reduce size by 15% to 20% during sintering. The mold used for MIM is designed to produce parts slightly larger than the final specifications to compensate for this shrinkage and achieve the desired final dimensions. This oversizing accounts for the anticipated shrinkage and ensures that the final parts meet the required tolerances.

It's essential for MIM manufacturers to carefully control the sintering process and monitor shrinkage to produce parts that meet precise specifications. The specific shrinkage value can vary based on the MIM materials and the specific MIM process used, so it's crucial to consider these factors when designing MIM components.

Causes of MIM Shrinkage

MIM Material Selection

MIM material optional is various. The choice of metal powder and binder material greatly influences shrinkage. Different metals and alloys have varying thermal expansion coefficients, which can result in different shrinkage levels during cooling. For example, the shrinkage rate of 316L stainless steel commonly used by Neway is 16.5%. Typical shrinkage of MIM materials ranges from 15% to 20%.

Cooling Rate

The rate at which the part cools during the MIM process can affect shrinkage. Rapid cooling may lead to higher shrinkage, while slower cooling can reduce it.

Tooling DesignThe design of the mold or tooling used in the MIM process can impact shrinkage. Factors such as mold temperature, material, and gating design can all influence the part's final dimensions.

Sintering Process

The sintering step, which involves heating the green part to remove the binder and consolidate the metal particles, is the main factor that introduces shrinkage. The sintering temperature and time are crucial in determining the extent of shrinkage.

MIM Parts Geometry

The shape and complexity of the part can influence shrinkage. For instance, thin-walled and intricate parts may experience more significant shrinkage than simple, solid shapes.

What Are The Consequences Of MIM Shrinkage?

Metal Injection Molding (MIM) shrinkage is a common phenomenon in the manufacturing process that involves reducing the size of a part as it goes through various stages, particularly during sintering.

Dimensional Inaccuracy

The most immediate consequence of shrinkage is dimensional inaccuracy. Parts may end up smaller than their design specifications, which can be problematic, especially for parts that require tight tolerances. Usually, the tolerance of MIM parts is 0.02mm.

Warpage and Distortion

Non-uniform shrinkage can lead to warpage or distortion of parts. It is especially true for complex geometries or parts with varying thicknesses. Warped or distorted parts may not fit or function as intended. It also results in MIM being unable to sinter oversized parts. Or the cost-effectiveness of sintering large parts is very low.

Aesthetic Issues

Shrinkage can result in aesthetic issues such as imperfections, uneven surfaces, or distorted features. It can be a problem for parts that require a smooth or precise finish. But even so, comparing precision casting parts, the MIM part surface is better. MIM parts can obtain mirror effects of various colors through surface treatment processes such as polishing and PVD.

Functional Problems

Shrinkage can affect the functionality of a part. For example, if a part is intended to fit precisely with another component, shrinkage may cause a poor fit or interference issues.

Tolerancing and Compensation

Designers often need to consider anticipated shrinkage by designing oversized parts. It requires careful consideration of tolerances and compensation factors.

评论

发表评论