CIM Alumina (Al2O3) Ceramic Injection Molding service

Alumina Ceramic Injection Molding (CIM) service offers a cutting-edge solution for producing intricate ceramic components with exceptional precision and consistency. Key features of CIM Al2O3, commonly known as aluminum, include its remarkable mechanical strength, high el electrical insulation properties, and excellent thermal stability.

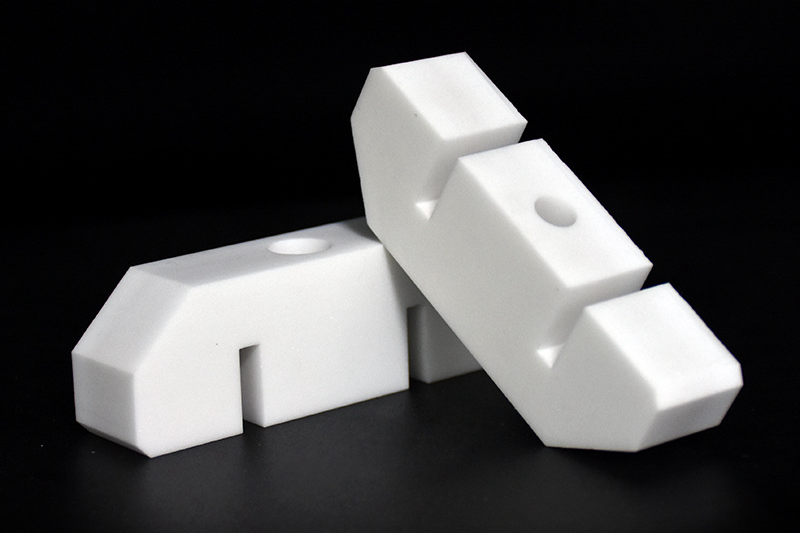

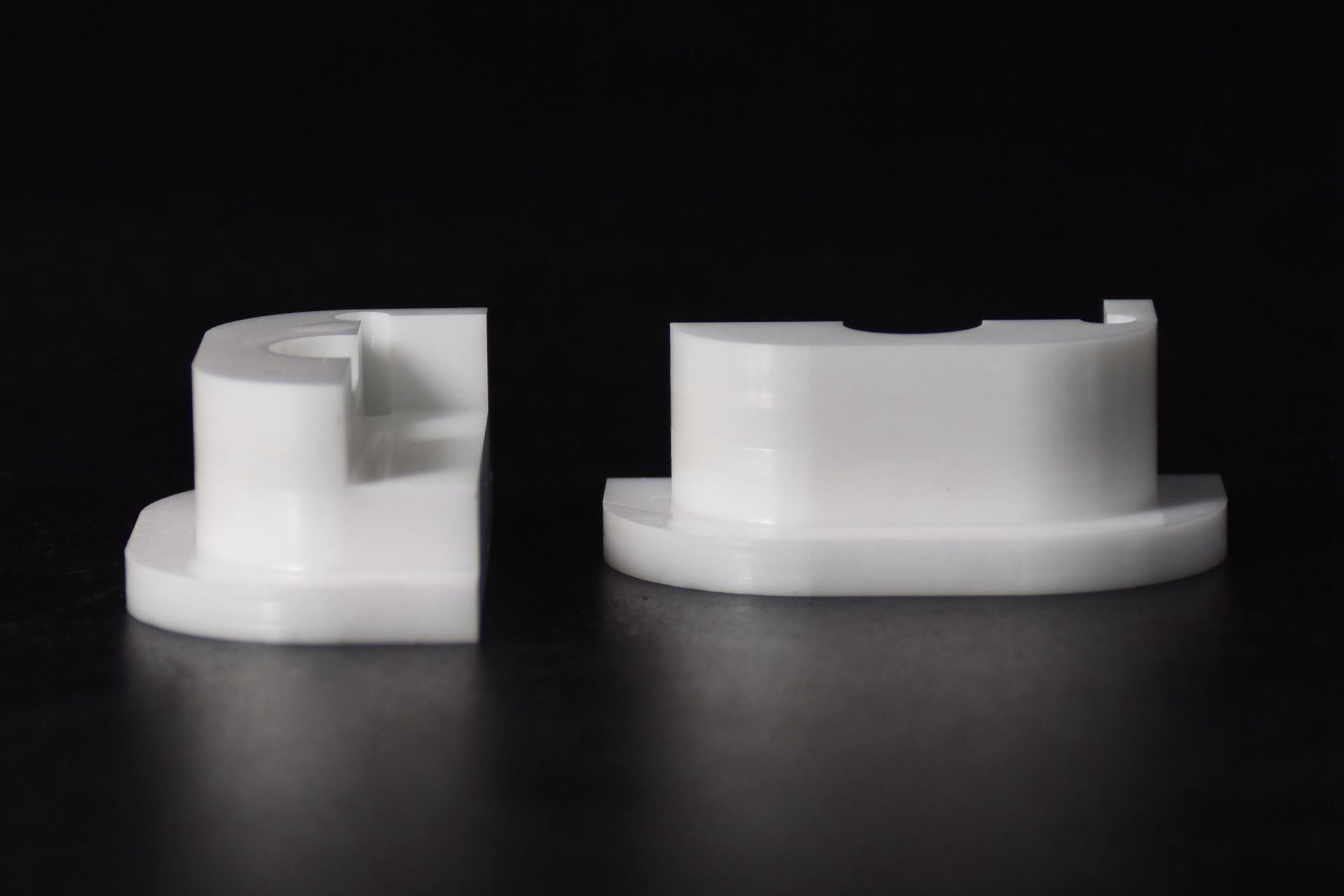

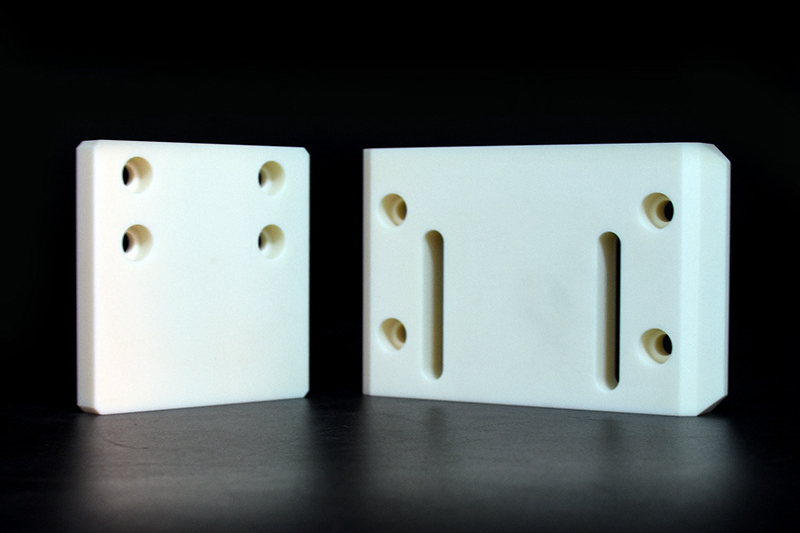

The Alumina Ceramic Injection Molding (CIM) parts combine the high complexity of the plastic injection molding process with the high performance of ceramic materials.

CIM Al2O3 parts are used in various applications, including Medical devices: CIM Al2O3 is used to make implants, prostheses, and other medical devices that require high strength and durability.

Electronics: CIM Al2O3 is used to make components for electronic devices, such as resistors, capacitors, and insulators.

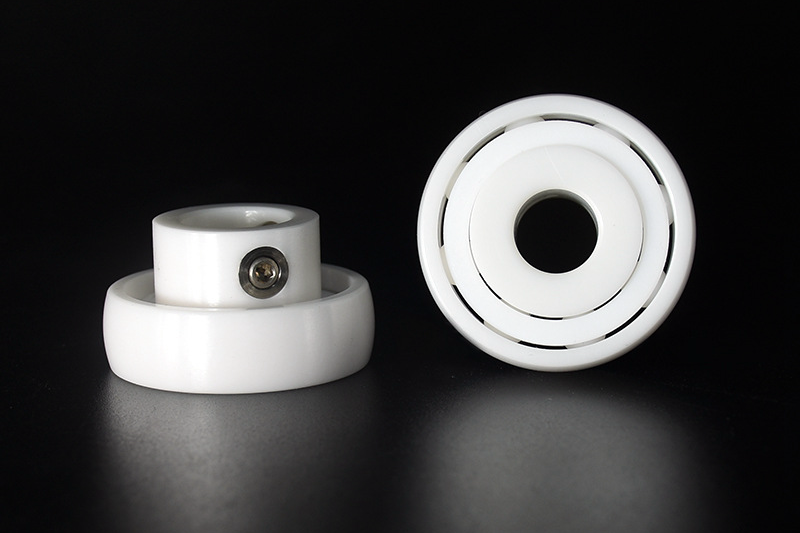

Industrial applications: CIM Al2O3 makes components for various industrial applications, such as pumps, valves, and bearings.

CIM Alumina (Al2O3) Typical Properties

Physics and Mechanical Properties

Properties | Fracture Toughness (MPa√m) | Flexural Strength (MPa) | Impact Strength (J/m) | Hardness (HRA) | Young's Modulus (GPa) | Elastic Modulus (GPa) | Thermal Expansion (10^-6/°C) | Compressive Strength (MPa) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

CIM Alumina (Al2O3) | 4.0 | 350 | 3.0 | 85 | 350 | 390 | 8.0 | 1900 | 4.0 |

Key Features And Applications of CIM-Al2O3 Parts

Hardness

Ceramic Injection Molding (CIM) Alumina (Al2O3) parts typically exhibit a hardness ranging from 80 to 90 HRA (Rockwell hardness scale). This high hardness level is a result of the intrinsic properties of alumina, making CIM-Al2O3 parts exceptionally resistant to wear and abrasion. This attribute is precious in applications where components experience friction, impact, or contact with abrasive materials.

Alumina (Al2O3) CIM parts find applications in industries requiring hardness properties, such as cutting tools and wear-resistant components. In cutting tools, the hardness of CIM-Al2O3 allows them to withstand the mechanical stress and friction generated during the machining process. Similarly, wear-resistant components benefit from the hardness of alumina by maintaining their integrity and performance even in abrasive environments.

The hardness of CIM-Al2O3 parts also makes them resistant to corrosion. This makes them suitable for applications where they will be exposed to chemicals or other corrosive environments.

Thermal Conductivity

Ceramic Injection Molding (CIM) Alumina (Al2O3) parts typically exhibit a high thermal conductivity, ranging from 20 to 35 W/m·K. This remarkable thermal conductivity stems from the crystalline structure of alumina, enabling efficient heat transfer.

Alumina (Al2O3) CIM parts find essential applications in industries requiring superior thermal conductivity properties. In electronics, CIM-Al2O3 heat sinks efficiently dissipate heat generated by electronic components, ensuring optimal device performance and longevity. Industrial processes, like those involving metal casting, benefit from alumina's ability to regulate temperature, enhancing process control.

Additionally, CIM-Al2O3 parts in high-temperature environments, such as gas turbine engine components, rely on thermal conductivity to withstand and manage extreme temperatures effectively.

Strength

Ceramic Injection Molding (CIM) Alumina (Al2O3) parts exhibit impressive strength characteristics, with typical flexural strengths ranging from 300 to 400 MPa. This strength results from the dense and uniform microstructure of alumina, which provides excellent resistance to applied forces and mechanical stresses. CIM-Al2O3 parts' strength makes them suitable for applications demanding durability, load-bearing capacity, and resistance to deformation under pressure or impact.

Alumina (Al2O3) CIM parts find crucial applications in industries that require robust strength properties. In the automotive sector, CIM-Al2O3 parts serve as components in engines and transmissions, where they endure mechanical forces and thermal cycles. Similarly, industrial machinery benefits from alumina's strength, with parts like ceramic bearings and cutting tools maintaining their integrity under high loads.

The strength of CIM-Al2O3 parts also makes them resistant to fatigue. This makes them suitable for applications where they will be subjected to repeated loading and unloading.

Chemical Inertness

Ceramic Injection Molding (CIM) Alumina (Al2O3) parts possess exceptional chemical inertness, exhibiting resistance to chemical reactions with most substances. This property is attributed to the stable crystalline structure of alumina, which makes CIM-Al2O3 parts suitable for applications in corrosive and reactive environments where chemical stability is paramount. The chemical inertness ensures minimal interaction with acids, bases, and other corrosive agents, contributing to the longevity and reliability of CIM-Al2O3 parts.

Alumina (Al2O3) CIM parts find vital applications in industries requiring superior chemical inertness properties. CIM-Al2O3 parts are used for valves, pipes, and reaction vessels that come into contact with aggressive chemicals in the chemical processing sector. Medical applications, including implants and surgical instruments, benefit from alumina's biocompatibility and resistance to bodily fluids.

Electrical Insulation

Electrical insulation is the ability of a material to resist the flow of electric current. Ceramic Injection Molding (CIM) Alumina (Al2O3) parts possess exceptional electrical insulation properties. With a high dielectric strength and low electrical conductivity, CIM-Al2O3 parts effectively prevent the flow of electric current. It makes them ideal for applications where electrical isolation is critical, such as insulators, circuit components, and electronic substrates, ensuring reliable operation and reducing the risk of electrical interference.

Alumina (Al2O3) CIM parts find essential applications in industries that demand robust electrical insulation properties. Electronics benefit from CIM-Al2O3 insulating components, ensuring reliable performance and preventing short circuits. The semiconductor industry utilizes CIM-Al2O3 substrates for their electrical isolation in electronic devices. In high-voltage applications, such as power distribution systems, CIM-Al2O3 insulators prevent unwanted electrical leakage and ensure safe operation.

Consultative Design Services

Neway Custom Metal Injection Molding Service provides free Consultative Design Services throughout the process. This includes all processes from your design stage to mass-produced finished products.

1. Material selection Consult

2. Structural design service

3. Mold design service

Contact us now if you are interested.

What We Can Offer?

We offer free material selection and consultative design services from beginning to end. No MOQs, Rapid prototyping, and mass production are our strengths.

Experience the versatility of CIM Al2O3 as we delve into its remarkable properties. From its high hardness thwarting wear to its remarkable electrical insulation and chemical resistance, Alumina (Al2O3) CIM parts redefine possibilities. Uncover how Alumina CIM parts thrive in applications demanding resilience, precision, and innovation. --- Neway R&D TEAM

评论

发表评论