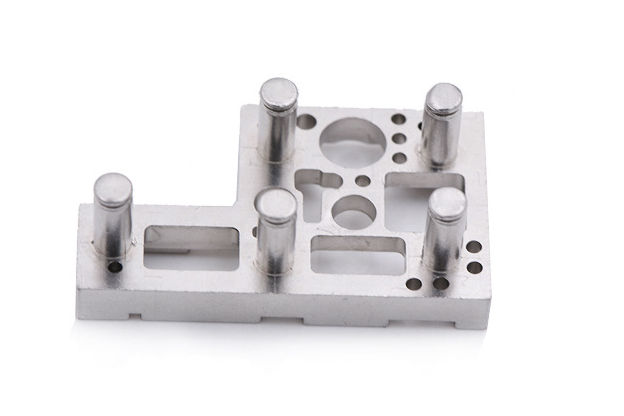

MIM-430 Stainless Steel Metal Injection Molding Service

Metal injection molding service of ferritic 430 stainless steel provides excellent corrosion resistance, formability, and ductility. Adding chromium provides oxidation and corrosion resistance superior to lower alloy steels. MIM refinement of the ferritic microstructure improves toughness and impact strength versus precision casting. Post-sintering annealing enhances ductility and formability.

The excellent corrosion resistance of MIM 430 stainless steel makes it well-suited for applications involving exposure to water, chemicals, and weathering, including marine components, medical devices, and food processing equipment. Good drawing ability also allows it to be readily formed into complex shapes. The material is commonly used for automotive trim parts, appliances, and architectural components where corrosion performance and formability are required.

Compared to other MIM stainless steel, metal injection molded 430 stainless steel provides an optimal balance of fabrication, mechanical properties, and corrosion resistance at a relatively low cost. These attributes make it an excellent choice for safety-critical applications across many industries.

MIM 430 Stainless Steel Typical Properties

Download PDF: MIM-430 Stainless Steel Datasheet |

|---|

Chemical Composition

Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Iron (Fe) | |

|---|---|---|---|---|---|---|---|

Weight % | 0.12 | 1.0 | 0.04 | 0.03 | 1.0 | 16.0 | Balance |

Physics and Mechanical Properties

Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRB) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|

Annealed | 515 | 205 | 100 | 80 | 200 | 0.27 | 45 | 7.7 |

Key Features And Applications of MIM-430 Parts

Weldability

MIM-430 stainless steel has excellent weldability due to its stable ferritic structure and low carbon content. It can be welded using joint fusion and resistance welding processes. Preheat is typically unnecessary, and post-weld stress relieving is generally unnecessary. Welds in 430 have flexibility similar to the base metal. Because of its lack of hardening or phase transformations during welding, MIM-430 is very resistant to cracking. With good joint preparation, proper heat input, and suitable filler material, MIM-430 stainless steel parts can be readily welded for complete penetration of structural joints, seals, and attachments while retaining corrosion resistance and mechanical properties.

Applications like Automotive exhaust parts, medical connectors, marine hardware, food processing equipment, appliances, architectural features, and chemical processing equipment benefit from MIM-430 stainless steel's weldability.

Corrosion-Resistance

The 16-18% chromium content of MIM-430 stainless steel provides excellent corrosion resistance and oxidation resistance at elevated temperatures. It performs very well in oxidizing acids and coastal/marine environments. MIM-430 resists pitting and crevice corrosion better than 400 series grades. However, it has less corrosion resistance than 300-series austenitic stainless steels overall. Proper passivation helps enhance corrosion performance. MIM-430 has suitable corrosion resistance for many architectural, marine, processing equipment, and mild chemical exposure applications while providing good formability and lower cost than higher alloys.

Typical applications requiring the corrosion resistance of 430 stainless steel MIM parts include marine components, medical devices, food processing equipment, architectural features, and automotive trim parts.

Formability and Ductility

MIM-430 stainless steel possesses good formability and ductility due to its stable ferritic microstructure. The material can be readily bent, drawn, stamped, and formed into complex shapes without losing mechanical properties.

MIM-430 exhibits elongation of around 45% in the annealed condition, allowing significant stretching and reduction during forming and fabricating. The properties also ensure good toughness and energy absorption.

The excellent ductility and formability of MIM-430 stainless make it well-suited for applications that require bending, shaping, stamping, and other fabrication processes to achieve the desired part geometry while retaining corrosion resistance. It facilitates the production of intricate components and allows design flexibility.

Cost Effective

MIM-430 stainless steel provides a cost-effective material solution thanks to its relatively low alloy content. The grade contains 16-18% chromium to resist corrosion and oxidation. This level of alloying makes MIM-430 more economical than 300 series austenitic grades, which have higher nickel content. It also avoids more expensive specialty alloys.

The corrosion performance of MIM-430 is sufficient for many architectural, marine, automotive, and industrial equipment applications. It allows overall cost savings versus higher alloys while meeting mechanical and environmental requirements. When cost control is a priority, MIM-430 stainless should be considered an affordable option.

Consultative Design Services

Neway custom metal injection molding service provides free Consultative Design Services throughout the process. This includes all processes from your design stage to mass-produced finished products.

1. Material selection Consult

2. Structural design service

3. Mold design service

Contact us now if you are interested.

What We Can Offer?

We offer free material selection and consultative design services from beginning to end. No MOQs, Rapid prototyping, and mass production are our strengths.

"When I needed precision parts for my automotive project, I turned to Neway's MIM-430 Metal Injection Molding service. The results were exceptional! The parts exhibited superior corrosion resistance and mechanical strength, precisely what I needed. The team's expertise and attention to detail left me impressed. Highly recommended!" -ROTH Machinery --- Jen.

"I can't recommend Neway's MIM services enough - the 430 stainless parts they produced for my marine application were flawlessly corrosion-resistant. Their expertise in designing for manufacturability was precious. As a new customer, I associated the 20% discount on my first order! Ditely take advantage of Neway's excellent full-scale MIM capabilities.”- VOGT Ultrasonics --- Rudolf.

评论

发表评论