Laser cutting is an efficient sheet metal fabrication service. It has revolutionized modern manufacturing, enabling the production of highly intricate, precise, and complex components. The demand for laser-cut parts has surged across industries like aerospace, automotive, electronics, and medical devices as engineers and designers push the boundaries of innovation. Laser cutting allows manufacturers to create geometries and features that are impossible through conventional machining or fabrication methods. This article will walk through the laser-cutting process step-by-step, examine the critical factors that influence cut quality, and highlight the advantages that make laser cutting a go-to technology for high-precision manufacturing.

Laser Cutting Process Step-by-Step

How exactly does laser cutting work to churn out such accurate, repeatable parts on a mass-production scale? Here's a play-by-play:

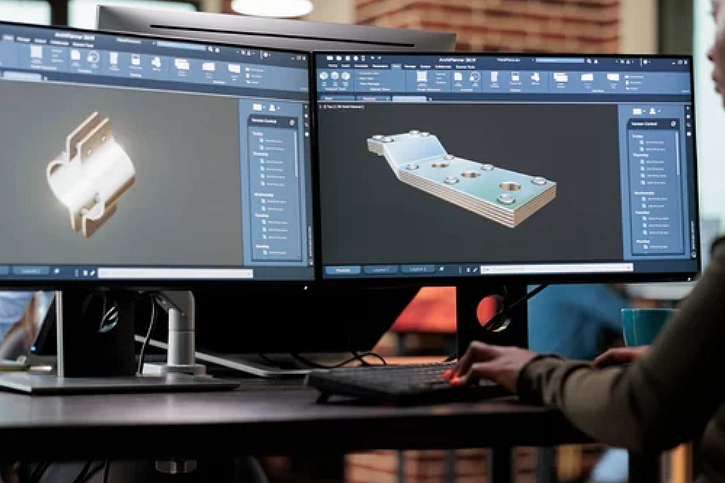

Design and Programming

It all starts with the right design. A CAD file is uploaded to the laser cutting machine, providing it with the patterns, shapes, and specifications to cut. The CAD file dictates the path the laser will follow as it cuts through the material. Programming includes:

Defining the cutting paths and nesting parts to maximize material use.

Setting parameters like speed and power.

Adding any necessary markings or modifications.

Generating the machine code that operates the laser cutter.

Careful programming before cutting begins is essential for achieving the finished laser-cut components' precision, efficiency, and quality.

Material Preparation

Material preparation is critical in producing high-quality laser cutting parts, including selecting the appropriate sheet size and material composition, ensuring adequate flatness and surface finish, fixturing parts properly, adding identifying marks, and inspecting stock material before cutting. Proper preparation (such as removing coatings, smoothing surfaces, and flattening sheets) allows consistent laser reflection and unimpeded cuts. Steps to fixture, register, and track parts also lead to higher-quality finished components. Overall, the effort spent on optimizing the raw material sets up the laser-cutting process for maximum efficiency and precision.

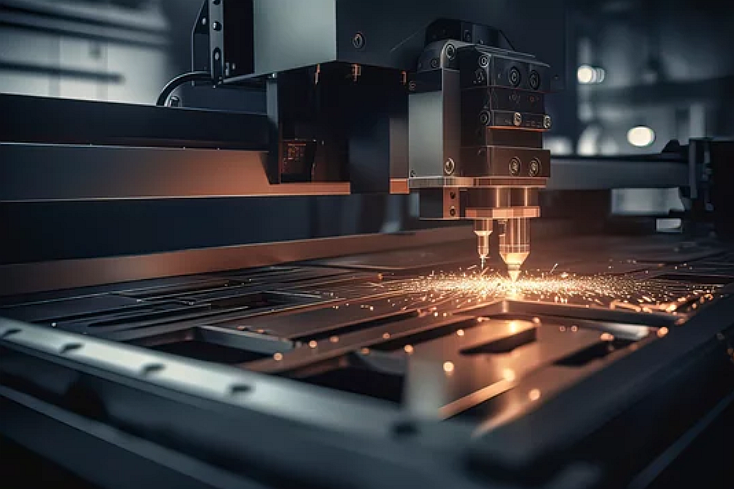

Laser Cutting

Laser cutting sheet metal is an exact, high-energy process. The concentrated power of the focused laser beam melts, burns, or vaporizes the metal along the programmed cut path. As the high-intensity laser beam traces the cutting pattern, it separates the sheet into cut-out pieces defined by the CAD model. The laser intricately follows the predefined toolpaths, penetrating the material while molten metal and vaporized gases are blown away by assist gas jets. The controlled motion of the cutting head combined with the high-temperature laser energy enables complex 2D profiles to be carved into the sheet metal with remarkable speed, precision, and repeatability. When the laser has completed tracing the patterns, finished cut components are left behind, ready for further post-processing or assembly.

Offload and Post Processing

Once the laser has completed its cutting program, the finished parts are carefully offloaded from the machine for post-processing to clean up the components and make them ready for use. It can involve removing slag, dross, or melted material along the cut edges using mechanical scraping or chemical baths. Further operations like grinding or sanding may smooth and polish the cut edges. Parts are also deburred to remove sharp points and corners. Additional steps can include bending, welding, or adding protective coatings. Proper offloading and post-processing ensure cut parts meet requirements and are ready for shipment or integration into final products.

Advantages of Laser Cutting

Neway custom laser cutting services provide customers with an efficient, high-quality solution for precision sheet metal cutting.

Precision - Laser cutting achieves high levels of accuracy and repeatability, with tight tolerances down to +/- 0.005 inch. Complex geometries and fine details can be produced.

Speed - Lasers cut faster than manual sawing, shearing, or machining. Production times can be reduced significantly.

Flexibility - Lasers can readily cut a wide range of materials, thicknesses, and shapes with minimal tooling costs. Easy to switch between jobs.

Automated - Laser cutting is highly automatable with CNC control, enabling uncrewed 24/7 operation. Human labor is minimized.

Clean cuts - The laser makes narrow, clean kerfs without mechanical force or contact. It prevents distortion and allows intricate patterns.

Waste reduction - Nesting software maximizes material utilization. Less waste compared to other cutting methods.

Versatile - Laser cutting service can offer prototyping, short runs, pre-production, and high-volume production.

Cost-effective - No expensive custom tooling is required. It saves time and labor compared to manual fabrication.

Consistency - Programmable process ensures high consistency and repeatability—standardization of parts.

Defects and Solutions of Laser Cutting

Although laser cutting has an irreplaceable role and advantages in sheet metal processing, there are also some congenital disabilities. With experience and by fine-tuning parameters, Neway can minimize defects. But these solutions can help troubleshoot and control the quality when they do occur.

Excessive Dross: Melted material that re-solidifies along the cut edge. Solution: Optimize cut parameters, and use nitrogen or air-assist gas.

Charring - Discoloration and burn marks from excessive heat. Solution: Reduce laser power, and increase cutting speed.

Striations - Vertical ridges along the cut from vibration or unstable laser power. Solution: Improve mechanical stability, and check the laser power supply.

Tapered Edges - Angled cut walls instead of clean vertical edges. Solution: Position the workpiece at the correct focus distance.

Edge Rounding: Blunted edges lack sharp definition. Solution: Reduce cutting speed, and refocus the laser properly.

Hole Distortion: Holes cut undersized or non-circular—solution: Balance power, speed, and gas pressure. Use conical lenses.

Burrs - Rough, jagged edges requiring secondary finishing. Solution: Finer beam focus, slower cutting speed, optimized gas pressure.

Warping: Heat effects cause parts to twist or deform. Solution: Pre-heat material, use chill plates, and change the cut path sequence

Experience of Neway R&D Team

Laser cutting has proven itself as an indispensable manufacturing process for precision parts across countless industries. The combination of highly accurate CAD modeling, CNC-controlled motion, and a concentrated heat source in the laser beam enables intricately complex geometries to be produced at remarkable tolerances.

While the core physics behind laser cutting remains unchanged, enhancements in laser power, beam quality, motion control, and monitoring have enabled ever more ambitious applications. Laser cutting drives innovation by allowing designers to imagine and produce components with previously impossible shapes, features, and minimized weight.

From aerospace and medical devices to electronics and automotive, manufacturers rely on laser cutting for rapid prototyping, low-volume production, and high throughput manufacturing. As laser technology progresses, so will the possibilities of what can be manufactured. Burgeoning areas like micro-cutting and remote laser processing hint at the continued evolution of this flexible, autonomous, and high-precision manufacturing process. By merging human creativity with laser precision, businesses can turn visions of next-generation designs into tangible, production-ready parts.

Neway's Custom Laser Cutting Service

Hey folks, let me clue you in on why Neway is the way to go for your custom laser cutting needs. For over 30 years, they've been cranking out precision parts with excellent manufacturing capabilities. We're talking injection molding, die casting, CNC machining, you name it. But laser cutting is their jam. Their state-of-the-art lasers will slice and dice your parts with micro-precision lickety-split. And for new customers, they'll hook you up with 20% off your first order. Pretty sweet deal if you ask me. Give Neway a shot for custom laser cutting—you won't be disappointed.

评论

发表评论