Ceramic Injection Moulding (CIM) has emerged as a revolutionary manufacturing process that combines the benefits of traditional injection molding with the versatility of ceramics. It allows for producing complex, high-quality injection molded ceramic components with precision and efficiency. But before diving into this exciting realm of manufacturing, it's crucial to understand the initial cost involved. In this article, we'll explore the ins and outs of the CIM process, factors influencing the initial cost, real-life examples, and strategies to optimize expenses. So, let's get started!

Overview of Ceramic Injection Molding Process

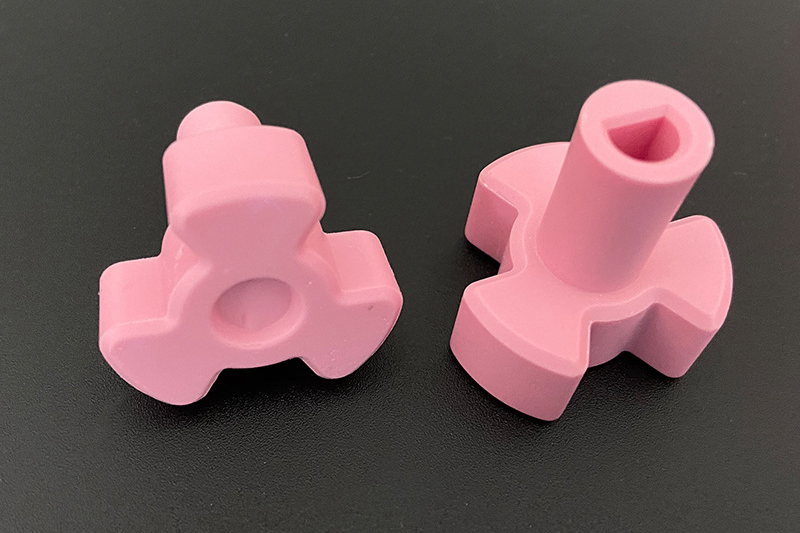

To grasp the initial cost, it's essential to understand how the CIM process works. Picture this: it's like baking a cake but with ceramics. First, a feedstock is prepared by combining fine ceramic powders with a binder material to form a slurry. This slurry is then injected into a mold cavity under high pressure injection molding, just like injecting batter into a cake mold. Once the material solidifies, the molded part is removed from the mold, and the binder is removed through a debinding process. Finally, the part is sintered at high temperatures to achieve the desired strength and density.

The CIM process involves several key components and equipment. Ceramic injection molded components such as injection molded ceramics require injection molding machines, molds, and auxiliary equipment like mixers, heaters, and coolers. All contribute to the successful production of ceramic components. These components and other factors influence the initial cost of CIM.

Factors Affecting the Initial Cost of Ceramic Injection Molding

Material Costs

Regarding CIM, the choice of CIM ceramic materials plays a vital role in determining the initial cost. Different types of ceramics possess varying properties and costs. For instance, advanced ceramics like alumina, zirconia, and silicon nitride offer exceptional strength and thermal resistance but tend to be more expensive. On the other hand, traditional ceramics like porcelain or earthenware are generally more cost-effective but may have limited applications. Material costs directly impact the overall expense of the CIM process.

Although the ceramic utilization rate of CIM is as high as 98%, the loss of 2% for more expensive materials must be addressed. So we can calculate the material cost in CIM based on this data.

CIM material cost = part weight / 0.98 * material unit price

Tooling Costs

Tooling, which includes the design and manufacturing of molds, is another significant contributor to the initial cost of CIM—the complexity and size of the part being produced influence the tooling requirements. Intricate designs with undercuts or fine details may necessitate more intricate molds, leading to higher tooling costs. Additionally, the number of cavities in the mold affects production volume and, consequently, the mold cost per part.

Because the calculation cost of the mold is more complicated, you can refer to how to calculate injection molding mold cost for details, but usually, we can estimate the volume and weight of the mold for parts with simple structures. Then calculate the material cost of the mold, and the mold processing cost of simple parts is about 2.5 times the mold material cost.

Equipment and Machinery Costs

Investing in injection molding of metals, ceramics machines, and auxiliary equipment is integral to ceramic injection molding. The cost of these machines can vary based on their capabilities, precision, and automation features. Higher precision and automation come at a higher price. CIM forming processing mainly include injection, debinding, and sintering. Automation and robotics can provide efficiency improvements but may require additional investment.

The equipment cost of CIM molding mainly includes injection molding, degreasing, and sintering costs.

CIM equipment cost=injection cost + degreasing cost + sintering cost

Labor Costs

CIM is a skilled labor-intensive process that demands expertise and precision. Skilled labor is essential for handling the various steps involved in the CIM process, from material preparation to debinding and sintering. The intricacy of the components being produced can further influence labor costs. Parts with complex geometries or fine details may require more time and skill, increasing the overall labor expenses.

Quality Control and Testing Costs

To ensure the quality and reliability of ceramic components, rigorous inspection and testing procedures are essential. The cost of specialized equipment and resources for quality assurance adds to the initial cost of CIM. These costs are crucial for maintaining consistency and meeting the desired specifications of the components.

Strategies to Optimize CIM Initial Cost

While the initial cost of CIM may seem daunting, there are strategies to optimize expenses and make the most of this advanced manufacturing process. Here are a few key considerations:

Design for Manufacturability (DFM) considerations

Collaborate with experienced CIM manufacturers early in the design phase to ensure the design is optimized for manufacturability. This can minimize material waste, simplify tooling requirements, and reduce labor-intensive steps.

Material selection and cost optimization

Explore different ceramic materials and their properties to find the right balance between performance and cost. Collaborate with material suppliers to identify cost-effective options without compromising on quality.

Tooling design and optimization

Work closely with tooling experts to design molds that are efficient and cost-effective. Consider factors like the number of cavities, complexity, and size of the part to optimize tooling costs.

Process optimization and efficiency improvements

Continuously analyze the CIM process to identify areas for improvement. Invest in process monitoring and control systems to enhance efficiency, reduce scrap rates, and save costs in the long run.

Collaborating with experienced CIM manufacturers

Partnering with experienced CIM manufacturers can provide valuable insights and expertise in optimizing the initial cost. Their knowledge and experience can help navigate the complexities of CIM and identify cost-saving opportunities.

Conclusion

Understanding the initial cost of ceramic injection molding is crucial for any CIM project. By considering factors like material costs, tooling expenses, equipment investments, labor requirements, and quality control, one can better estimate and optimize the expenses associated with CIM. While the initial cost may vary depending on the specific requirements of each project, leveraging strategies like DFM considerations, material and tooling optimization, process improvements, and collaborating with experienced manufacturers can help minimize costs while reaping the benefits of CIM. So, don't shy away from exploring ceramic injection molding as a viable and innovative manufacturing option. The possibilities are endless!

评论

发表评论