Surface treatment is vital in enhancing plastic parts' visual appeal and durability. The In-mold Decoration (IMD) process has emerged as an innovative method in recent years.

IMD Usually interpreted as injection molding surface treatment technology or injection molding surface decoration technology, IMD is currently an internationally famous surface decoration technology, mainly used in surface decoration and functional panels of home appliances, commonly used in mobile phone window lenses and casings, washing machine control panels, refrigerators Control panels, air conditioner control panels, car dashboards, rice cooker control panels, panels, signs, and other appearance parts in various fields.

Understanding the In-mold Decoration (IMD) Process

Unlike other plastic surface treatment processes, the In-mold Decoration (IMD) process involves integrating decorative elements onto the surface of a plastic part during the injection molding process. It is a highly efficient technique that eliminates the need for post-molding decoration, resulting in cost and time savings. Using specialized films, graphics, or labels, IMD allows for intricate and visually appealing designs on plastic parts.

IMD is divided into IML and IMR. The most significant difference between these two processes is whether there is a transparent protective film on the product's surface.

In Mold Labeling

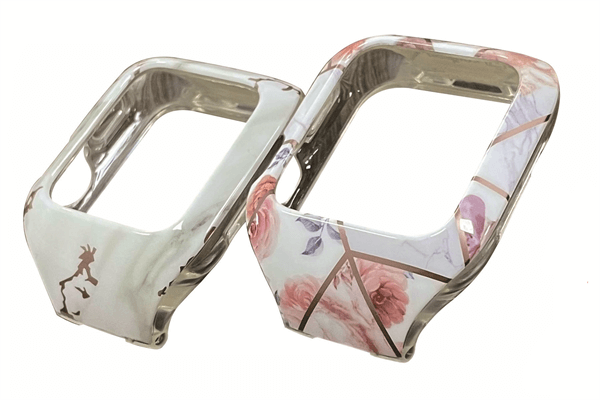

IML: In-mold labeling Injection molding has very remarkable features. The surface is a layer of hardened transparent film, the middle is a printed pattern layer, and the back is a plastic layer. Because the ink is sandwiched in the middle, the product can prevent the surface from being scratched. Flowers and abrasion resistance can keep the color bright for a long time and not easy to fade. IML is also known as IMF (In-mold film).

In-Mold Roller

IMR: In-mold transfer printing. This process prints the pattern on the film and uses the film-feeding machine to fit the film and the mold cavity for injection molding. After injection, the patterned ink layer is separated from the film, and the ink layer remains on the plastic part. There is no transparent protective film on the surface of the final product, and the film is only a carrier in the production process. However, the advantage of IMR lies in the high degree of automation in production and the low cost of mass production. Disadvantages of IMR: The printed pattern layer is on the product's surface, and the thickness is only a few microns. After a period of use, the printed pattern layer is easy to wear off and fade, resulting in an unsightly surface. In addition, the new product development cycle is long, the development cost is high, and the pattern color cannot be flexibly changed in small batches, which are weaknesses the IMR process cannot overcome.

Advantages of Using IMD for Surface Treatment

IMD offers numerous advantages over traditional surface treatment methods. Firstly, it provides enhanced design possibilities and aesthetics, making it an ideal mold decoration technique. The ability to incorporate complex designs, textures, and colors during the molding process opens up new creative avenues for product designers. Additionally, IMD provides excellent durability and scratch resistance, ensuring that the decorative elements remain intact even under harsh conditions.

Moreover, IMD offers significant cost and time savings compared to post-molding decoration methods. By integrating decoration during molding, manufacturers can eliminate the need for additional production steps, reducing costs and lead times. Furthermore, IMD ensures consistency and repeatability in decoration, guaranteeing that every finished product has the same high-quality appearance.

Steps Involved in the IMD Process

The IMD process involves several sequential steps to achieve the desired surface treatment.

Firstly, mold preparation and design considerations are crucial in-mold decoration. The mold must be designed to accommodate the decorative film and ensure proper adhesion during the injection molding.

Next comes the printing and decoration process of in-mold labeling. The specialized film is precisely printed with the desired graphics, textures, or labels, integral parts of the in-mold labeling process. This step requires precision and expertise to ensure accurate reproduction of the intended design.

Once the film is ready, it is placed in the mold, and injection molding takes place, a critical step in mold labeling injection molding. The plastic material is injected into the mold, effectively integrating the decoration onto the part's surface. This integration creates a seamless and durable bond between the plastic material and the decorative elements.

After the injection molding process, demolding and finishing steps are carried out. The finished parts are carefully removed from the mold, and any excess material or imperfections are addressed. These finishing steps ensure that the final product meets the desired quality standards.

Benefits of In-mold Decoration (IMD)

Design Possibilities and Aesthetics

IMD offers unparalleled design possibilities and aesthetics for plastic parts. The ability to incorporate intricate details, vibrant colors, and unique textures directly into the surface of the part opens up new horizons for product designers. With IMD, manufacturers can create visually stunning products that stand out.

Durability and Scratch Resistance

IMD provides exceptional durability and scratch resistance, making it an excellent mold decoration solution. Integrating the decoration into the part's surface protects the decorative elements from external factors such as abrasion, chemicals, or UV exposure. This ensures the design remains intact and visually appealing for the product's lifespan.

Cost and time savings

One of the significant advantages of IMD is the cost and time savings it offers. Manufacturers can streamline production workflows by eliminating the need for post-molding decoration processes, such as painting or labeling. This reduction in steps translates into significant cost savings and shorter lead times, ultimately benefiting both manufacturers and end consumers.

Consistency and Repeatability

IMD ensures consistency and repeatability in decoration. As the decoration is integrated during the injection molding, every part produced has the same high-quality appearance. This uniformity is critical, especially in industries where brand image and product consistency are essential.

Applications of In-mold Decoration (IMD)

IMD finds extensive applications across various industries. IMD is commonly used in the consumer electronics industry to enhance the appearance of smartphones, tablets, and other electronic devices. The seamless integration of logos, patterns, or textures onto the surface of these devices creates a premium and visually appealing product.

Automotive industry

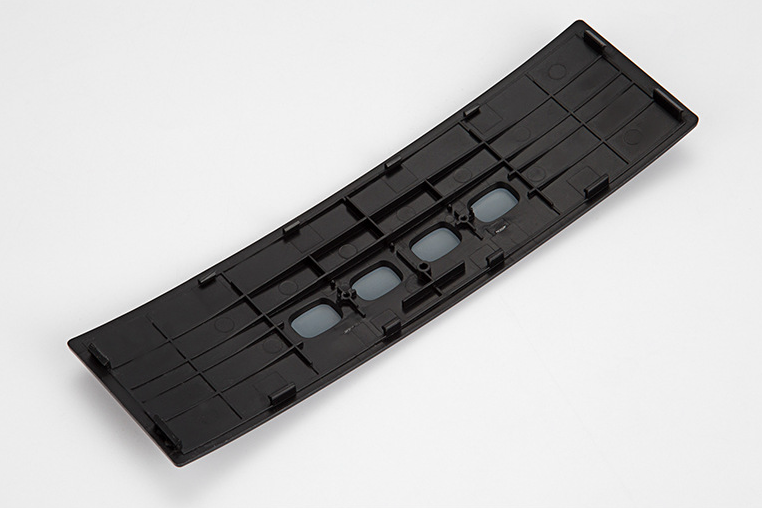

IMD is utilized for interior and exterior parts. From instrument panels to door trims, IMD enables manufacturers to achieve sophisticated designs that elevate the overall aesthetic appeal of vehicles. IMD's durability and scratch resistance are particularly beneficial in the automotive sector, where parts are exposed to harsh environments.

Appliances and household

Appliances and household goods also benefit from IMD. Kitchen appliances, home decor items, and even toys can be enhanced with the use of IMD. The ability to incorporate eye-catching designs and textures transforms ordinary objects into visually appealing products that resonate with consumers.

Medical device

IMD has found applications in the medical devices and healthcare products industry. The ability to integrate labeling or instructions directly onto the surface of medical devices ensures vital information remains accessible throughout the product's lifespan. IMD also allows for a more hygienic surface, as there are no crevices or edges where bacteria can accumulate.

Challenges and Limitations of IMD

Despite its many advantages, IMD does present specific challenges and limitations. Design limitations and considerations are crucial when employing IMD. The mold design must accommodate the decorative film and ensure proper adhesion. Complex or intricate designs may require advanced techniques or specialized equipment, impacting production costs.

Compatibility with different resins and materials is another consideration in in-mold labeling. IMD works best with certain plastics, such as ABS or PC/ABS blends. Compatibility issues may arise when using other resins or materials, requiring additional testing and adjustments to achieve the desired results.

Quality control and production issues can also pose challenges in IMD. As the decoration is integrated during the injection molding process, any imperfections or defects can be challenging to rectify. Maintaining strict quality control measures throughout production ensures consistent and high-quality results.

Why Choose Neway

As we enter 2023, Neway Precision is excited to extend a special offer to new customers. We believe in the quality of our services and want you to experience it firsthand. That's why we offer a generous 20% discount on your first order. Take this opportunity to discover the unmatched craftsmanship, attention to detail, and reliable customer support that Neway is known for. Take advantage of this limited-time offer and start your manufacturing journey with Neway today.

评论

发表评论