Plastic injection molding produces plastic parts by injecting molten plastic into a mold cavity. In two-shot molding, two different plastics are injected in sequence into one mold to create a two-material or two-color part. Multi-shot molding injects three or more shots of plastic into a single mold to create parts with multiple materials or colors. Overmolding involves injecting one material onto a pre-molded part already placed in the mold, combining two materials into one part. Multi-shot and overmolding combine different properties like flexibility, strength, and texture into one part. They increase design freedom but require more complex tooling than standard injection molding.

Injection Molding

Injection molding is a typical manufacturing process for producing plastic parts in high volumes. The primary plastic injection molding process involves melting plastic material into liquid and injecting it under high pressure into a mold cavity. The plastic cools and solidifies inside the mold, taking the shape of the mold cavity.

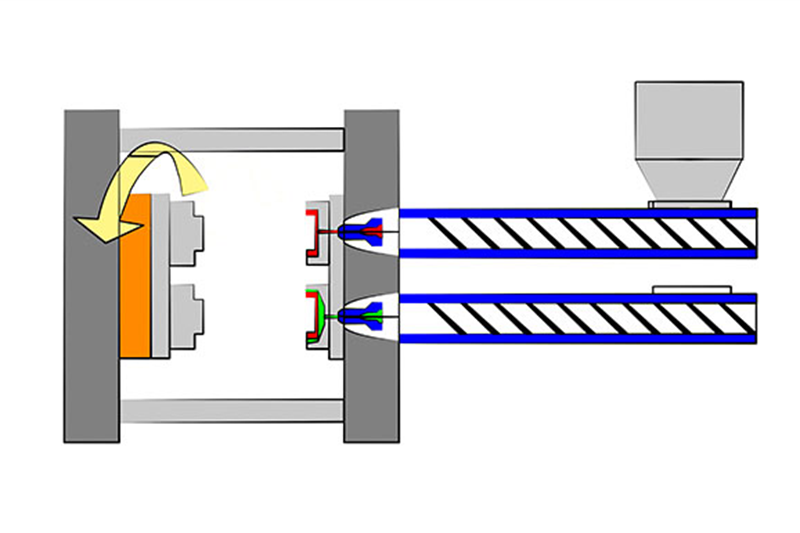

The process starts by feeding small plastic feedstocks into a hopper that feeds the injection molding machine. The pellets are melted inside a heating barrel using heaters and rotating screws. Once molten, the plastic is injected through a nozzle into the mold cavity with a clamping unit keeping the mold closed under pressure.

Inside the mold, channels cut into the mold allow coolant to circulate and solidify the plastic. Once cooled, the mold opens, and the finished plastic part is ejected. The mold then closes, and the cycle repeats.

Injection molding is known for its speed, repeatability, and ability to produce complex geometries efficiently. Parts have tight tolerances and low scrap rates. Although injection molds have high initial costs, injection molding has a low per-part cost at high volumes, making it ideal for mass production.

Two-shot injection molding

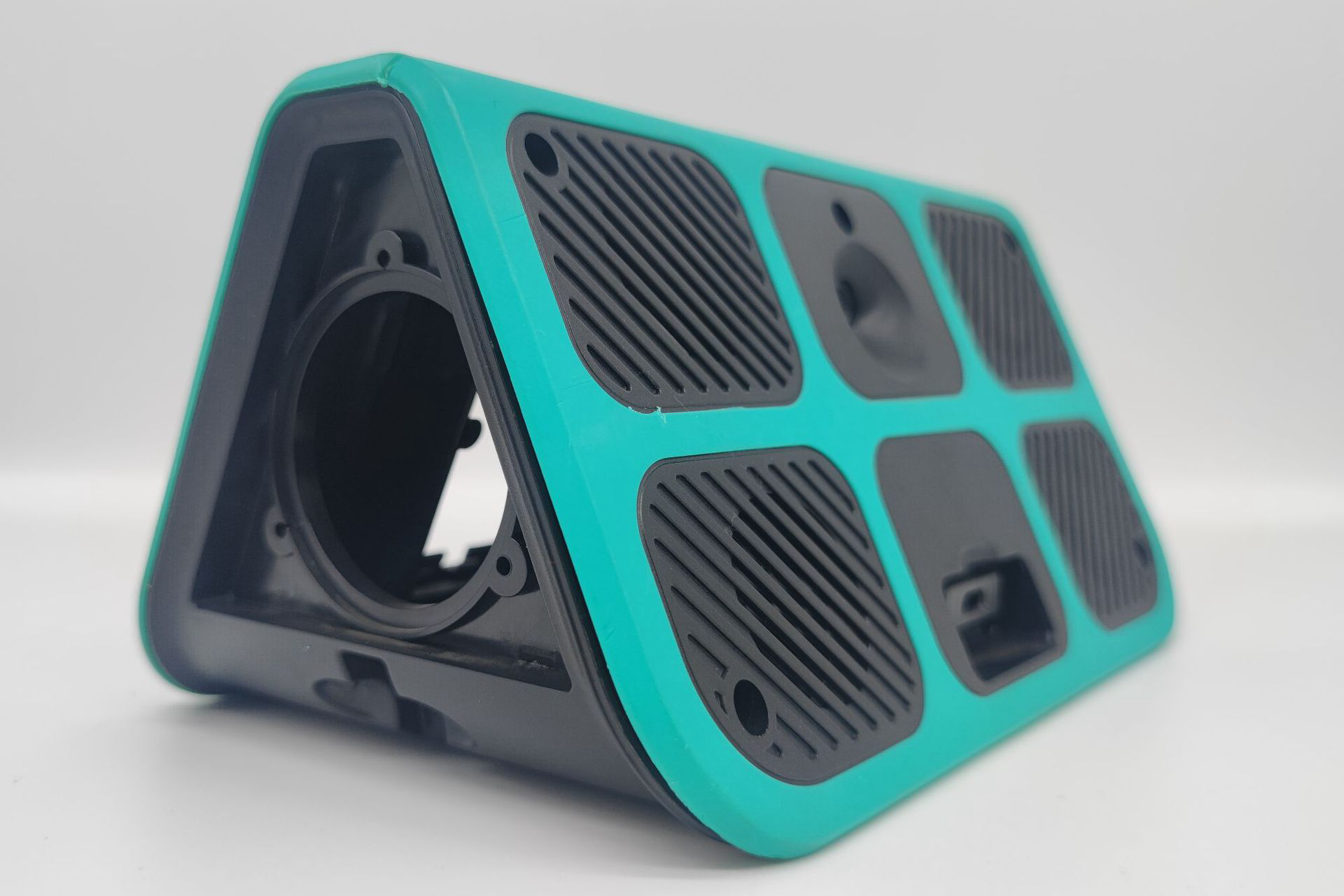

Two-shot injection molding, also known as 2K molding or two-color injection molding, is a plastic molding process that combines two different plastic materials into a single part.

In this process, two separate plastic materials are injected sequentially into the same mold cavity. The first shot forms the core part; the second shot molds a second material onto the core. The two materials bond through thermal and molecular diffusion, creating a two-material or two-color component with unique properties.

To keep the two melts separate, the two-shot molding requires specialized injection molding machines and molds with two separate barrel and nozzle systems. It combines the advantages of two plastics, such as flexible and rigid polymers, into one part.

Benefits of two-shot molding include design flexibility, consolidated part assembly, cost-effectiveness, and achieving a combination of characteristics like soft-touch grips or rubber seals bonded to rigid plastic. Two-shot molding is ideal for complex products with decorative effects like control panels, automotive trim, medical devices, and consumer goods.

Pros and cons of two-shot injection molding

Two-shot molding provides unique advantages but requires more investment and process expertise than conventional single-shot injection molding.

Pros:

Combines two materials into one part, eliminating assembly

Achieves multi-color and multi-material parts

Lowers costs compared to assembling two parts

Provides design flexibility not possible with one material

Automates overmolding process

Strong bonding between two materials

Allows mixing different properties like rigid/flexible

Hides visible joints between materials

Consistent quality and reliability

Cons:

Higher tooling costs than single-shot molding

More complex processes requiring specialized equipment

Needs extensive expertise to design and produce

Limitations on material combinations based on bonding and viscosity

Higher pressure requirements than single-shot

Slower cycle times due to multiple injections

Higher scrap rate if process not optimized

Challenging to combine more than two materials

Material separation can occur if bonding is poor

Need to balance shrinkage rates of two plastics

Multi-Shot Injection Molding

Multi-shot injection molding involves injecting two or more different plastic materials sequentially into a single mold cavity to produce complex, multi-material plastic parts in one shot.

In a multi-shot process, the mold has multiple nozzles injected into the same cavity at different times. The first shot of molten plastic is injected and allowed to partially or fully harden. Next, a second shot of a different material is injected against the first, followed by more injections as needed.

The multi-shot molding requires specialized injection molding machines with additional injection units and complicated hot runner systems to deliver the separate melts. Each material must be compatible with the other and have proper bonding characteristics.

The multi-shot process allows the combining of three or more plastic materials into one part. It provides design flexibility to integrate different properties, colors, finishes and functions into one component. Multi-material parts can integrate soft touch grips, seals, gaskets, hinges, and clear window lenses into a single molded part.

Multi-shot molding consolidates assembly processes, reduces labor, and improves durability over multi-part assemblies. It is ideal for complex products like auto interior trim, consumer electronics, medical devices, and industrial parts. However, the molds and equipment are complex, requiring significant expertise.

Pros and Cons of Multi-Shot Injection Molding

Multi-shot molding can produce innovative multi-material parts but requires very complex processing and high initial costs compared to standard injection molding. Pros:

Combines three or more materials into one part

Achieves complex multi-material and multi-color effects

Consolidates complex assemblies into one component

Lowers manufacturing costs compared to assembling multiple parts

Provides unique design flexibility and product innovation

Allows combining incompatible materials in one product

Improves bond strength between different materials

Automates overmolding and assembly operations

Higher quality and consistency versus assembling separately

Cons

A very high initial investment in complex molds and equipment

Requires advanced expertise in process and mold design

Significant process optimization is needed for material compatibility

Slower cycle times due to multiple injections

Higher scrap rates, if not optimized properly

Limitations on material combinations based on bonding

Challenging to combine more than five different materials

Very costly to change or modify molds

Higher maintenance costs for complex systems

Need to balance shrinkage rates of all materials

Material separation can occur if bonding is poor

Overmolding

Overmolding is a plastic molding process where one material is molded onto a second pre-formed material. It combines two different components into a single part.

The process starts with the first material being molded to create the core component. It is known as the substrate or substrate part.

The substrate is then loaded into a second mold cavity where the second material is injection molded to form an outer layer around the substrate. It is known as overmolding.

The two materials bond together to create the final over-molded part. The substrate provides the core strength while the overmold provides a gripping surface, seal, gasket, or adds aesthetic appeal.

Overmolding allows the combining different properties, like rigid and flexible polymers, into one part. It eliminates the assembly of separate components with fasteners or adhesives.

Some examples of over-molded parts include toothbrushes with soft grips, rubber seals molded onto metal components, and handles molded onto tools. The substrate can be plastic, metal, wood, or pre-assembled sub-components.

Overmolding is ideal for cost-effectively combining the benefits of disparate materials into one part with enhanced functionality. It simplifies assembly and improves reliability.

Overmolding provides unique advantages but requires material selection, mold design, and process optimization expertise.

Pros and cons of overmolding

Pros:

Combines different materials into one part

Consolidates assembly of separate components

Provides design flexibility not possible with one material

Allows combining incompatible materials

Achieves multi-material and multi-color effects

Lowers manufacturing cost vs. assembling multiple parts

Automates assembly operations like adding grips or seals

Adds functionality by combining properties like rigid/flexible

Improves ergonomics and aesthetics

Simplifies designs by reducing fasteners and joints

Improves bond strength between different materials

Consistent quality and reliability

Cons:

Requires two distinct manufacturing processes

Needs expertise in selecting compatible materials

Material shrinkage rates must be compatible

Limitations on a substrate and overmold materials

The substrate part must be designed for overmolding

Cycle time longer than standard molding

Higher initial mold costs

Potential for over-molded layer separation over time

Assembly may still be required if the substrate is complex

Substrate imperfections and knit lines may show

Higher scrap rate if process not optimized

Challenging to combine more than two materials

Two-Shot and Multi-Shot Injection Molding Vs. Over Molding

Two-shot and overmolding combine two materials using sequential molding, while multi-shot allows complex combinations of three or more materials through multiple injections into one mold. Overmolding also differs by using a pre-formed substrate part. All provide unique part consolidation and property integration, but multi-shot is the most complex process.

Two-Shot Molding:

Combines only two different plastic materials into one part

Two materials inject sequentially into one mold

Achieves two-color and rigid/flexible material parts

Lower complexity and cost vs. multi-shot molding

Multi-Shot Molding:

Combines three or more different plastic materials

Multiple injection units inject into one mold sequentially

Produces complex multi-material and multi-color parts

The highest complexity, initial cost, and process expertise needed

Overmolding:

Second material molded over a pre-formed substrate material

Substrates can be plastic but also metal, wood, etc.

Automates assembly of grips, seals, etc., onto a substrate

Lower complexity than multi-shot, only two materials

The substrate must be explicitly designed for overmolding

How to Choose the Right Injection Process?

The optimal choice depends on product requirements, volumes, budget, design needs, and production capabilities.

The number of materials: Two-shot combines 2 materials, multi-shot can combine 3+ materials, and overmolding usually just 2 materials.

Part complexity: Multi-shot can make the most complex multi-material parts. Overmolding is limited if the substrate is complex.

Tooling cost: Multi-shot molds are the most expensive. Over molds need two tool sets, and two-shot tools fall in between.

Production volumes: Two-shot is better for medium-high volumes. Overmolding is better for low-volume production or plastic prototyping. Multi-shot is only viable for high volumes to amortize tooling.

Material selection: Material compatibility and bonding are crucial, especially for multi-shot with more materials.

Process expertise: Multi-shot requires the most extensive process know-how. Two-shot is less complex.

Equipment cost: Multi-shot machines are the most expensive. Standard presses can do two-shot and overmolding.

Cycle time: Multi-shot has the longest cycle times due to multiple injections. Two-shot faster than overmolding.

Initial investment: Multi-shot requires the highest investment in equipment and tooling. Two-shot and overmolding have lower startup costs.

Design flexibility: Multi-shot offers the most innovative design possibilities with multiple materials.

Assembly consolidation: Multi-shot and two-shot integrate most assembly steps. Overmolding depends on the substrate.

Why Choose Neway Injection Molding?

Neway has been the premier producer of specialized injection molded, cast, and fabricated parts for three decades. Their meticulous craftsmanship and engineering expertise elevate every project to new heights. Custom metal, ceramic, and plastic components are sculpted to perfection through their advanced manufacturing capabilities. Every unique prototype and production part receives white-glove treatment from their talented technicians. To celebrate its 30th anniversary in 2023, Neway is offering new customers an introductory 20% discount on initial orders. Please take advantage of their unparalleled quality and experience at an even more appealing price. Bring your imagination, and Neway will make it a reality.

评论

发表评论