Overview of Investment Casting

Investment casting, also called lost-wax casting, is a manufacturing technique with a rich investment casting history spanning thousands of years. It's renowned for its capacity to produce parts with superior surface finish, high dimensional accuracy, and intricate details. This process is utilized across many industries, such as aerospace, automotive, and medical, to create parts that may be challenging to manufacture using other casting methods. The investment casting process is a testament to the versatility and precision of Investment & precision casting Ltd.

Process of Investment Casting

The investment casting process encompasses several crucial steps. Following is the investment casting process step-by-step:

Pattern Creation

The journey begins with creating a wax pattern that mirrors the final product. This pattern is typically crafted using injection molding, where molten wax is injected into a metal mold (die) and left to solidify.

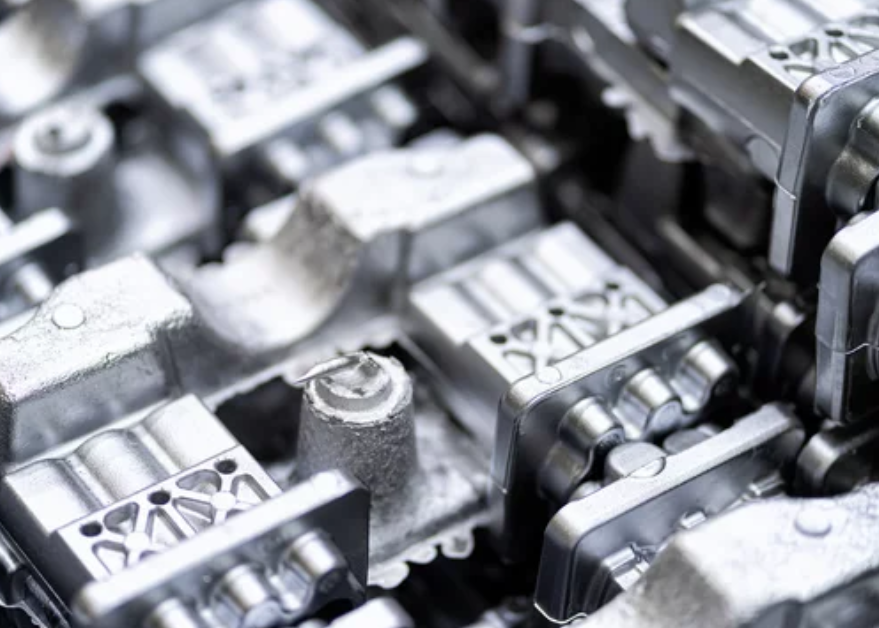

Assembling Wax Patterns and Tree Formation

After the wax patterns are crafted, they are assembled onto a sprue to form a structure resembling a tree. This assembly permits multiple parts to be cast simultaneously, enhancing the efficiency of the investment casting process.

Mold Shell Formation

The wax tree is subsequently dipped into a ceramic slurry to form a shell around the wax patterns. This shell is developed through multiple dips, with drying time between each dip.

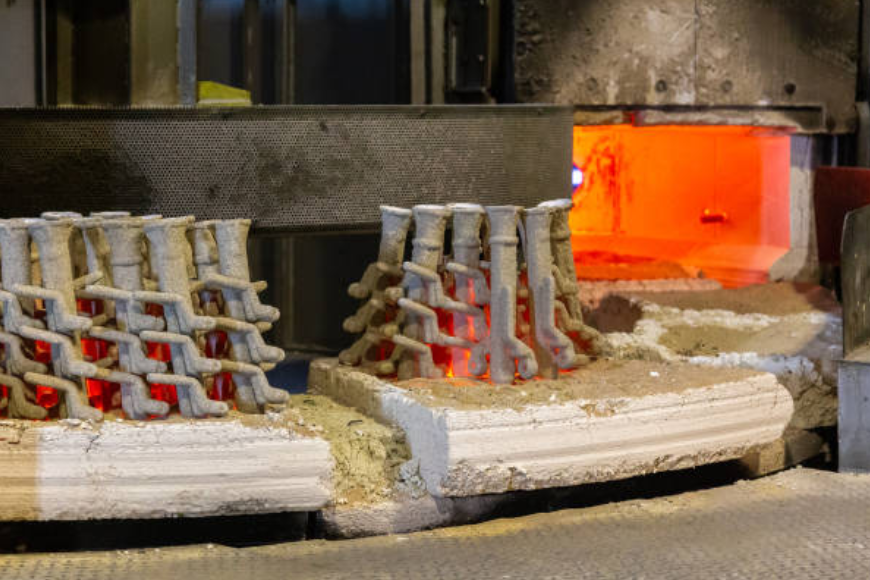

Wax Removal

Once the ceramic shell is dry, the wax is melted in a furnace, resulting in a hollow mold. This step gives the lost wax process its name.

Melting and Casting

The mold is then preheated and filled with molten metal. The metal solidifies within the ceramic mold, forming the final part of the investment casting process.

Final Operations

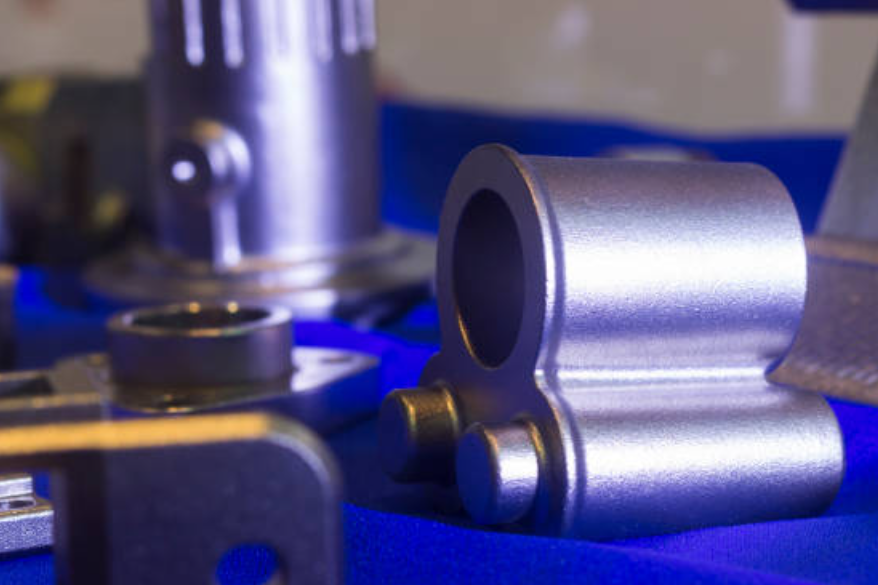

After the metal has cooled and solidified, the ceramic shell is broken away, and the individual parts are cut from the sprue. To achieve the final dimensions and surface finish, the parts undergo finishing processes, such as grinding, sanding, or machining.

Overview of Materials Used in Investment Casting

The versatility of investment casting is evident in the various investment casting materials that can be utilized. The selection of Investment casting materials hinges on several factors, including application, cost, mechanical properties, and casting characteristics. The most frequently used materials encompass various types of steel, aluminum, and special alloys, demonstrating the broad scope of the investment casting process.

Diverse Materials in Investment Casting

Investment casting accommodates a broad spectrum of materials, each offering unique properties:

Stainless Steel

Renowned for its corrosion resistance and excellent mechanical properties, stainless steel is frequently employed in food processing, medical, and marine applications.

Material Classification | Material Grade | Applicable Process | Datasheet |

Austenitic Stainless Steel | 304 (CF8) | Investment Casting | 304 Datasheet |

Austenitic Stainless Steel | 316 (CF8M) | Investment Casting | 316 Datasheet |

Martensitic Stainless Steel | 410 (CA15) | Investment Casting | 410 Datasheet |

Martensitic Stainless Steel | 17-4 PH (CB7Cu-1) | Investment Casting | 17-4 PH Datasheet |

Ferritic Stainless Steel | 430 (CF3) | Investment Casting | 430 Datasheet |

Duplex Stainless Steel | 2205 (CD3MN) | Investment Casting | 2205 Datasheet |

Low Alloy Steel

This material offers improved mechanical properties compared to carbon steel. It's often used in applications that require high strength and toughness.

Material Classification | Material Grade | Applicable Process | Datasheet |

Low Alloy Steel | 4130 (L80) | Investment Casting | 4130 Datasheet |

Low Alloy Steel | 4140 (L80) | Investment Casting | 4140 Datasheet |

Low Alloy Steel | 4340 (L80) | Investment Casting | 4340 Datasheet |

Low Alloy Steel | 8620 (L80) | Investment Casting | 8620 Datasheet |

Low Alloy Steel | 8630 (L80) | Investment Casting | 8630 Datasheet |

Low Alloy Steel | 9310 (L80) | Investment Casting | 9310 Datasheet |

Cast Aluminum

Lightweight and corrosion-resistant, cast aluminum is used in various industries, including automotive and aerospace.

Material Classification | Material Grade | Applicable Process | Datasheet |

Aluminum Alloy | A356 | Investment Casting | A356 Datasheet |

Aluminum Alloy | A357 | Investment Casting | A357 Datasheet |

Aluminum Alloy | 6061 | Investment Casting | 6061 Datasheet |

Aluminum Alloy | 7075 | Investment Casting | 7075 Datasheet |

Aluminum Alloy | 356-T6 | Investment Casting | 356-T6 Datasheet |

Aluminum Alloy | 380 | Investment Casting | 380 Datasheet |

Carbon Steel

Carbon steel is a cost-effective material that offers a good balance of strength and flexibility in investment casting.

Material Classification | Material Grade | Applicable Process | Datasheet |

Carbon Steel | 1010 | Investment Casting | 1010 Datasheet |

Carbon Steel | 1020 | Investment Casting | 1020 Datasheet |

Carbon Steel | 1030 | Investment Casting | 1030 Datasheet |

Carbon Steel | 1045 | Investment Casting | 1045 Datasheet |

Carbon Steel | 1080 | Investment Casting | 1080 Datasheet |

Carbon Steel | 4140 | Investment Casting | 4140 Datasheet |

Super Alloy

Superalloys are used for their ability to withstand high temperatures and corrosive environments. They are commonly used in jet engines and industrial gas turbines.

Material Classification | Material Grade | Applicable Process | Datasheet |

Nickel-based Superalloy | IN718 | Investment Casting | IN718 Datasheet |

Nickel-based Superalloy | IN625 | Investment Casting | IN625 Datasheet |

Nickel-based Superalloy | IN713C | Investment Casting | IN713C Datasheet |

Nickel-based Superalloy | IN738 | Investment Casting | IN738 Datasheet |

Cobalt-based Superalloy | Mar-M-247 | Investment Casting | Mar-M-247 Datasheet |

Cobalt-based Superalloy | Haynes 25 | Investment Casting | Haynes 25 Datasheet |

Cast Iron

Known for its excellent castability and machinability, cast iron is often used in automotive and industrial applications.

Material Classification | Material Grade | Applicable Process | Datasheet |

Gray Iron | Class 20 | Investment Casting | Class 20 Datasheet |

Gray Iron | Class 30 | Investment Casting | Class 30 Datasheet |

Gray Iron | Class 40 | Investment Casting | Class 40 Datasheet |

Ductile Iron | 65-45-12 | Investment Casting | 65-45-12 Datasheet |

Ductile Iron | 80-55-06 | Investment Casting | 80-55-06 Datasheet |

Ductile Iron | 100-70-03 | Investment Casting | 100-70-03 Datasheet |

Copper Alloy

Copper alloys, including brass and bronze, are known for their excellent conductivity and corrosion resistance.

Material Classification | Material Grade | Applicable Process | Datasheet |

Copper Alloy | C83600 | Investment Casting | C83600 Datasheet |

Copper Alloy | C92200 | Investment Casting | C92200 Datasheet |

Copper Alloy | C95400 | Investment Casting | C95400 Datasheet |

Copper Alloy | C95800 | Investment Casting | C95800 Datasheet |

Copper Alloy | C17200 | Investment Casting | C17200 Datasheet |

Copper Alloy | C17510 | Investment Casting | C17510 Datasheet |

Special Alloys

Special alloys are used for specific applications that require unique properties. These can include high strength at high temperatures, magnetic properties, or resistance to wear. Such Titanium alloys, Cobalt Alloys, and Nickel Alloys

Material Classification | Material Grade | Applicable Process | Datasheet |

Titanium Alloy | Ti-6Al-4V | Investment Casting | Ti-6Al-4V Datasheet |

Titanium Alloy | Ti-6Al-2Sn-4Zr-2Mo | Investment Casting | Ti-6Al-2Sn-4Zr-2Mo Datasheet |

Cobalt-based Superalloy | CoCrMo | Investment Casting | CoCrMo Datasheet |

Cobalt-based Superalloy | MP35N | Investment Casting | MP35N Datasheet |

Nickel-based Superalloy | Rene 41 | Investment Casting | Rene 41 Datasheet |

Nickel-based Superalloy | Hastelloy X | Investment Casting | Hastelloy X Datasheet |

Surface Treatments in Investment Castings

Surface treatments are applied to investment castings to enhance their aesthetic appeal, improve corrosion resistance, modify material properties, and shield the surface from external influences. The requirements of the final product determine the type of Investment casting surface treatment used.

Various Surface Treatments in Investment Casting

Investment casting employs several surface treatment methods:

Plating

Electroplating

Electroplating is a process that uses electrical current to reduce dissolved metal cations in a solution and coat a conductive object with a thin layer of the metal. The part to be plated is immersed in a solution containing metal salts and acts as the cathode (negative electrode). The anode (positive electrode) is also immersed in the solution and is made of the metal that will form the plating. When an electric current is applied, metal ions in the solution are attracted to the part's surface, depositing a thin metallic coating. Electroplating coats objects with a metal layer to enhance corrosion and wear resistance, change surface friction, improve aesthetics, and more. Typical metals used in electroplating include chromium, nickel, copper, zinc, tin, gold, and silver. Electroplating is widely used in industry and manufacturing for coating parts, auto bodies, jewelry, tools, and more. Its key benefits are its ability to quickly and economically plate objects with uniform coatings quickly and economically.

PVD plating

PVD (Physical Vapor Deposition) is a coating process that applies skinny, high-performance coatings onto parts and products. It works by heating the coating material until it vaporizes and deposits as a thin film onto the coated surface. PVD allows for precise control and can deposit metals, ceramics, and other materials to improve hardness, corrosion resistance, wear resistance, and other properties. It is used across many industries, including tools, automotive, aerospace, medical, and more. Its key benefits include depositing thin, uniform coatings with excellent adhesion while providing attractive finishes. Overall, PVD enables versatile, high-quality coatings for various demanding applications.

Polishing

Polishing is a process that creates a smooth, lustrous surface finish using abrasives. In polishing, an excellent abrasive compound is repeatedly applied to the surface and rubbed in a circular motion. This gradually removes delicate layers of material, smoothing the surface and enhancing reflectivity. A polished surface has minimal roughness and a mirror-like brightness. Polishing is commonly used on metals, glass, and plastics in applications ranging from finishing manufactured parts to restoring clarity to headlights. It provides aesthetic benefits like shine and light reflection while smoothing the surface to prevent contamination buildup and ease cleaning. Polishing is a versatile finishing method that enhances visual appearance and functional performance through controlled abrasion, creating a smooth, glossy surface texture.

Surface Hardening

Surface hardening is a process where only the surface layer of a metal part is selectively hardened while the core remains tough and ductile. Various methods include infusing the surface with carbon or nitrogen, rapidly heating, quenching the surface, and laser melting. This creates a tough, wear-resistant outer layer able to withstand friction, abrasion, and erosion, while the softer core provides strength and shock resistance. Surface hardening is widely used in automotive, aerospace, and manufacturing to selectively reinforce wear-prone areas on metal components like gears, shafts, and bearings. It provides an extended part of life in demanding environments. Overall, surface hardening lets manufacturers optimize strength, hardness, and wear properties in one part.

Powder Coating

Powder coating is an industrial finishing process where a dry powder material is applied to a surface and then cured under heat to form a hard, uniform coating. The powder particles are given an electrostatic charge to stick to the grounded target surface during application. The coated parts are heated to melt and fuse the particles into a smooth, durable film. Powder coating can apply much thicker coatings than conventional painting, providing excellent corrosion resistance, chip resistance, hardness, and durability. It is commonly used to coat metals and is valued for its efficiency and high-quality finish. Powder coating is a versatile industrial method that produces tough, uniform, protective, attractive coatings.

Tolerances in Investment Casting

Investment casting is capable of delivering excellent, repeatable as-cast tolerances. With as-cast capabilities of +/- three standard deviations when a single point is repeatedly measured—typically +/- .003 to +/- .004 per inch. Part configuration primarily influences tolerance capability and can vary depending on your part design.

Tolerance Capability in the Investment Casting Process

Several factors influence the tolerance capability of the investment casting process.

- Factors Influencing Tolerance Capability

Part configuration significantly influences tolerance capability. Symmetrical shapes with uniform wall sections solidify with significantly less variation than non-uniform and non-symmetrical wall sections.

- As-Cast Capabilities

The investment casting process can achieve excellent as-cast tolerances, typically +/- .003 to +/- .004 per inch.

Linear Tolerances

Linear tolerances for regular dimensions reflect three sources of variation:

- Prediction of Part and Casting Shrinkage Factors

This accounts for about 20% of the variation in tolerance.

- Diemaker and Tooling Tolerance

This accounts for about 10% of the variation in tolerance.

- Process Variation

This accounts for about 70% of the linear tolerance. The variation in tolerance is a combination of part configuration effects that result in non-uniform shrinkage and all other process variations in producing a wax pattern, ceramic mold, and casting.

Strategies for Achieving Premium Linear Tolerances

All three sources of variation can be reduced by:

- Part Redesign

Including the addition of tie bars, ribs, and gussets.

- Tuning of Wax Injection Tooling

After the first sample meets nominal dimensions.

- Straightening/Coining

- Additional Inspection/Gaging

- Machining

Superior tolerance capability can be achieved but must be considered on a part-by-part, dimension-by-dimension basis. Signicast can hold +/- .002" in some features, although +/- .004" per inch is a more typical premium cast tolerance.

Advantages of the Investment Casting Process

Investment casting offers several advantages:

-Investment castings size range: Investment casting can produce parts of virtually any size, from small to large.

- Versatile and Intricate Shapes: The process allows for producing parts with complex geometries that would be difficult to achieve with other manufacturing methods.

- Accurate and Smooth Surfaces: Investment casting can achieve excellent surface finishes and high dimensional accuracy without additional machining.

- Dimensional Accuracy: The process offers excellent, repeatable as-cast tolerances.

- Quality and Integrity: Investment cast parts have excellent mechanical properties and structural integrity.

Considerations When Using Investment Casting

While investment casting offers many advantages, there are also some investment casting considerations to keep in mind:

- Tooling Cost: The initial cost can be high, especially for complex parts.

- Size Limitations: While investment casting can produce parts of virtually any size, limitations may be based on the foundry's capabilities.

- Very Small Structures: Tiny and intricate structures may be difficult to cast accurately.

- Timing: The investment casting process can be time-consuming, especially for complex parts or large production runs.

Conclusion

Investment casting is a versatile manufacturing process that offers many advantages, including producing complex parts with excellent surface finish and high dimensional accuracy. However, it's essential to consider the specific requirements of your project, including the desired material, surface treatment, and tolerances, when deciding whether investment casting is the right choice for you.

评论

发表评论