What is hot pressing sintering?

Hot pressing sintering is a manufacturing process that uses heat and pressure to create strong, durable parts. The process involves heating a powder material to a high temperature, typically between 1000 and 2000 degrees Celsius, and then applying pressure to the material. The heat causes the powder particles to sinter, or fuse together, and the pressure forces the particles to pack more tightly together, resulting in a denser, stronger part.

Hot pressing sintering can produce various parts, including bearings, gears, seals, and other components used in various industries. The process is particularly well-suited for materials that are difficult to sinter using traditional methods, such as ceramics, metal powders, polymer powders, and composites. Compared with pressureless sintering, hot pressing sintering can produce a higher density of composite materials or metal powders.

How does it work?

Hot pressing sintering is a versatile and efficient manufacturing process that can create various strong, durable, and precise parts. Here are the steps involved in hot pressing sintering:

Powder preparation

Like the metal injection sintering process, the first step is to prepare the powder material. The powder is typically made by grinding or milling a solid material into small particles. The size of the particles is essential, as it affects the strength and density of the final product. The powder is then mixed with a binder, which helps to hold the particles together during the sintering process.

Die Preparation

The next step is to prepare the die. The die is the mold that the powder is pressed into. The die is typically made of a material that can withstand the high temperatures and pressures of the sintering process. The die is also designed to allow for the escape of gases that are generated during the sintering process.

Powder pressing

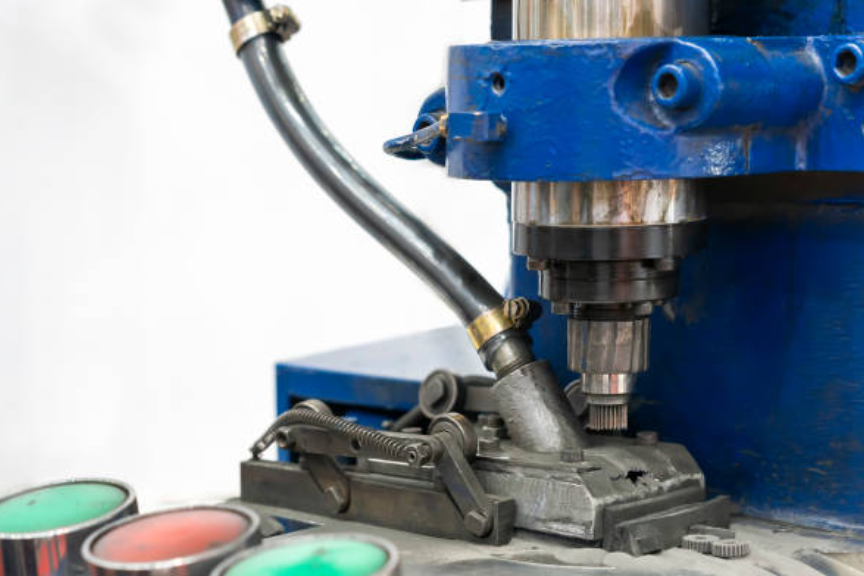

In the die pressing and sintering step, the powder is placed in the die. The powder pressing is typically compacted using a hydraulic powdered metal press machine. The compaction helps to ensure that the powder is evenly distributed in the die and that there are no voids.

Sintering Process

The die is then placed in a furnace and heated to a high temperature. The temperature is typically between 1000 and 2000 degrees Celsius. The heat causes the particles in the powder to sinter or fuse. The pressure applied to the powder during compaction helps to force the particles to close together, creating a denser material.

Cooling

Once the sintering process is complete, the die is removed from the furnace and cooled. The cooling process helps to strengthen the material and to prevent it from warping.

Part removal

Once the material has cooled, the part is removed from the die. The part is typically cleaned and inspected to meet the desired specifications.

History of hot pressing sintering

Hot pressing sintering is a manufacturing process that uses heat and pressure to create strong, durable parts. The process was first developed in the early 1900s, and it has been used to create a wide variety of parts, including bearings, gears, seals, and other components for use in various industries. Hot pressing sintering does not produce more complex shapes than metal injection sintering.

The basic idea of hot pressing sintering is quite old. Resistance heating of cemented carbide powders was patented by Tayler as early as 1933. This method is currently undergoing renewed interest. Current can be pulsed or unpulsed DC or AC. Spark plasma sintering (SPS) is a common name for this technique. However, it is technically incorrect since no spark and plasma have been validated. Other common names for this technique are Direct Current Sintering, Rapid Hot Pressing, and Direct Hot Pressing, amongst others.

Research facilities such as universities and institutes take advantage of the short sinter cycles, which speed up the research process. Recent development work includes metal-diamond-composite heat sinks, for example, in LED and laser applications. Sintering metal-diamond compounds with direct hot presses goes back to the 1950s, commonly practiced in the diamond tool industry.

In the 1960s, hot pressing sintering began to be used in the aerospace industry to create high-performance parts. The automotive industry also used the process to create parts that could withstand high temperatures and pressures.

In the 1980s, hot pressing sintering began to be used in the medical industry to create implants and other medical devices. The electronics industry also uses the process to create components that require high strength and durability.

Today, hot pressing sintering is a widely used manufacturing process. The process is used to create various parts for various industries.

What are the benefits of hot pressing sintering?

Hot pressing sintering is a manufacturing process that uses heat and pressure to create strong, durable parts. The process has several benefits, including:

High strength and durability

Hot pressed parts are typically much stronger and more durable than parts sintered using traditional methods. This is because the high temperature and pressure of the hot pressing process cause the particles in the powder to sinter more completely, resulting in a denser material with fewer defects.

Precise dimensional control

Hot pressing sintering can create parts with exact dimensional tolerances. This is because the pressure of the hot pressing process helps to force the particles in the powder to close together, resulting in a more uniform and consistent shape.

Reduced manufacturing costs

Hot pressing sintering can be a more cost-effective manufacturing process than traditional methods, such as machining or casting. This is because hot pressing sintering can create parts with complex shapes and features that would be difficult or expensive to machine or cast.

Improved surface finish

Hot pressing sintering can produce parts with a much improved surface finish than traditional sintering methods. This is because the high temperature and pressure of the hot pressing process help to close up any pores or voids in the material, resulting in a smoother and more uniform surface.

Reduced sintering time

Hot pressing sintering can reduce the sintering time required for some materials. This is because the hot pressing process's high temperature and pressure help accelerate the sintering process, resulting in shorter manufacturing cycles.

Improved mechanical properties

Hot pressing sintering can improve the mechanical properties of some materials. This is because the hot pressing process's high temperature and pressure help strengthen the material, resulting in parts with improved tensile strength, compressive strength, and fatigue resistance.

Hot pressing sintering is a versatile and efficient manufacturing process that can create various strong, durable, and precise parts. The process offers some benefits over traditional sintering methods, including improved strength, durability, dimensional control, surface finish, and mechanical properties.

The different types of hot pressing sintering

Hot pressing sintering is a manufacturing process that uses heat and pressure to create strong, durable parts. The process can be divided into two main types:

Conventional hot pressing

In conventional hot pressing, the powder is placed in a die and then heated to a high temperature. The pressure is applied to the die, and the powder is sintered under pressure.

Spark plasma sintering (SPS)

SPS is a newer type of hot pressing that uses a high-current electric field to heat the powder. The electric field causes the powder to heat up rapidly, and the pressure is then applied to the die. SPS is a much faster process than conventional hot pressing, and it can be used to create parts with complex shapes and features.

Advantages of SPS over conventional hot pressing:

Faster sintering time: SPS is a much faster process than conventional hot pressing. This is because the electric field causes the powder to heat up rapidly, which reduces the overall sintering time.

Improved mechanical properties: SPS can improve the mechanical properties of some materials. This is because the high-current electric field causes the powder to sinter more uniformly, resulting in a denser material with fewer defects.

Reduced manufacturing costs: SPS can be a more cost-effective manufacturing process than conventional hot pressing. This is because SPS can create parts with complex shapes and features that would be difficult or expensive to create using conventional methods.

Hot pressing sintering materials

The specific material used with hot pressing sintering will depend on the desired properties of the final product. For example, a ceramic process or injection molding metal may be used if a high-strength, durable part is required. A composite may be used if a lightweight, strong part is required.

Hot pressing sintering is a versatile process that can process various materials. The process offers several benefits, including improved strength, durability, dimensional control, surface finish, and mechanical properties. These benefits make hot pressing sintering an attractive option for various applications.

Material | Description | Applications | Specific Grade |

Ceramics | A class of materials that are made from inorganic materials, such as clay, sand, and metals. Ceramics are typically strong, durable, and resistant to high temperatures. They are often used in applications where high strength and durability are required, such as in the aerospace and automotive industries. | Cutting tools, wear-resistant parts, heat-resistant parts, electrical insulators, and bioceramics | Alumina (Al2O3), Silicon carbide (SiC), Zirconia (ZrO2) |

Metals | A class of materials that are made up of atoms that are bonded together by metallic bonds. Metals are typically strong, ductile, and conductive. They are often used in applications where strength, ductility, and conductivity are required, such as in the construction and manufacturing industries. | Engine components, structural components, tooling, and electronic components | Steel, Stainless steel, Titanium |

Composites | Materials that are made up of two or more different materials. Composites are often used in applications where high strength, durability, and/or lightweight are required, such as in the aerospace and automotive industries. | Sports equipment, marine components, and orthopedic implants | Carbon fiber composites, Glass fiber composites, Kevlar composites |

Other materials | Hot pressing sintering can also be used to process other materials, such as polymers and plastics. These materials are often used in applications where high strength, durability, and/or lightweight are required, such as in the medical and electronics industries. | Medical implants, electronic components, and sensors | Polyethylene (PE), Polypropylene (PP), Polytetrafluoroethylene (PTFE) |

The applications of hot pressing sintering

Hot pressing sintering is a versatile process that can create various parts for various applications. Some of the most common applications of hot pressing sintering include:

Cutting tools

Hot pressed cutting tools are often used in the aerospace and automotive industries. They are typically made from ceramics, such as alumina or silicon carbide, which are strong, durable, and resistant to wear.

Wear-resistant parts

Hot pressed wear-resistant parts are often used in mining, oil, gas, and other industries with a lot of wear and tear. They are typically made from ceramics, such as tungsten carbide and ceramic process, which are very hard and resistant to wear.

Heat-resistant parts

Hot pressed heat-resistant parts are often used in the aerospace and automotive industries. They are typically made from ceramics, such as zirconia, which can withstand high temperatures without deforming.

Electrical insulators

Hot pressed electrical insulators are often used in the electrical and electronics industries. They are typically made from ceramics, such as alumina, which are good insulators and can withstand high temperatures.

Bioceramics

Hot pressed bioceramics are often used in the medical industry. They are typically made from ceramics, such as alumina or zirconia, which are biocompatible and can be used to make implants and other medical devices.

Why should you use hot pressing sintering for your next project?

If you are seeking a hot pressing company for your projects where hot pressing sintering might be a good choice:

Creating high-performance components for the aerospace and automotive industries: Hot pressed parts are often used because they are strong, durable, and can withstand high temperatures.

Manufacturing wear-resistant parts for mining, oil, gas, and other industries where there is a lot of wear and tear: Hot pressed parts are often used because they are very hard and resistant to wear.

Developing heat-resistant parts for the aerospace and automotive industries: Hot pressed parts are often used because they can withstand high temperatures without deforming.

Creating electrical insulators for the electrical and electronics industries: Hot pressed parts are often used because they are good insulators and can withstand high temperatures.

Producing bioceramics for the medical industry: Hot pressed parts are often used in the medical industry because they are biocompatible and can be used to make implants and other medical devices.

These are just a few examples of the many projects where hot pressing sintering might be a good choice. Hot pressing sintering is an excellent option if you want a manufacturing process to create strong, durable, and precise parts.

How can hot pressing sintering help you save time and money?

Hot pressing sintering can help you save time and money in a few ways.

Reduced manufacturing costs

Hot pressing sintering can be a more cost-effective manufacturing process than traditional methods, such as machining or casting. This is because hot pressing sintering can create parts with complex shapes and features that would be difficult or expensive to machine or cast.

Improved surface finish

Hot pressing sintering can produce parts with a much improved surface finish than traditional sintering methods. This is because the high temperature and pressure of the hot pressing process help to close up any pores or voids in the material, resulting in a smoother and more uniform surface.

Reduced sintering time

Hot pressing sintering can reduce the sintering time required for some materials. This is because the hot pressing process's high temperature and pressure help accelerate the sintering process, resulting in shorter manufacturing cycles.

In the aerospace industry

Hot pressing sintering is often used to create high-performance components, such as turbine blades and engine parts. These components are often made from ceramics, which are strong, durable, and can withstand high temperatures. Hot pressing sintering can help to reduce the manufacturing time and cost of these components by up to 50%.

In the automotive industry: Hot pressing sintering is often used to create wear-resistant parts, such as brake pads and clutch discs. These parts are often made from ceramics, which are very hard and resistant to wear. Hot pressing sintering can help to reduce the manufacturing time and cost of these parts by up to 30%.

In the medical industry: Hot pressing sintering is often used to create bioceramics, such as implants and other medical devices. These materials are often made from ceramics, which are biocompatible and can be used to make implants and other medical devices. Hot pressing sintering can help to reduce the manufacturing time and cost of these materials by up to 20%.

How can hot pressing sintering improve the quality of your products?

Hot pressing sintering is a manufacturing process that uses heat and pressure to create a dense, strong, and consistent product. It can create various products, including ceramics, metals, and composites.

There are many ways that hot pressing sintering can improve the quality of your products. Here are a few examples:

Improved strength

Hot pressed products are typically much stronger than products sintered using traditional methods. This is because the high temperature and pressure of the hot pressing process cause the particles in the powder to sinter more completely, resulting in a denser material with fewer defects.

Improved durability

Hot pressed products are also typically much more durable than products sintered using traditional methods. This is because the hot pressing process's high temperature and pressure help strengthen the material, resulting in less likely of breaking or cracking products.

Improved dimensional control

Hot pressing sintering can create products with exact dimensional tolerances. This is because the pressure of the hot pressing process helps to force the particles in the powder to close together, resulting in a more uniform and consistent shape.

Improved surface finish

Hot pressed products can have a much improved surface finish than products sintered using traditional methods. This is because the high temperature and pressure of the hot pressing process help to close up any pores or voids in the material, resulting in a smoother and more uniform surface.

Reduced manufacturing costs

Hot pressing sintering can be a more cost-effective manufacturing process than traditional methods, such as machining or casting. This is because hot pressing sintering can create products with complex shapes and features that would be difficult or expensive to machine or cast.

Overall, hot pressing sintering is a versatile and efficient manufacturing process that can create a wide variety of strong, durable, and precise products. The process offers a number of benefits over traditional sintering methods, including improved strength, durability, dimensional control, surface finish, mechanical properties, and reduced manufacturing costs.

评论

发表评论