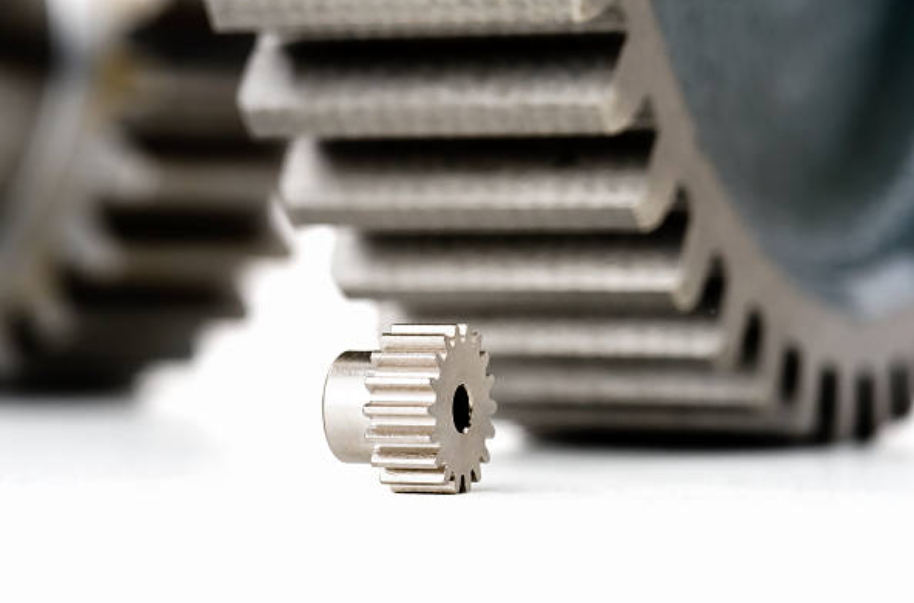

Welcome to the intricate world of Metal Injection Molding (MIM), a manufacturing process that marries the versatility of plastic injection molding with the strength and resilience of powder metallurgy. MIM offers a unique proposition for mass production, enabling the creation of complex, precision parts across a variety of industries. This blog aims to provide a comprehensive understanding of the MIM process, its pros and cons, and the critical considerations for mass production.

What is Metal Injection Molding

Metal Injection Molding (MIM) is a transformative manufacturing technology that has been shaping the industrial landscape for decades. But what exactly is MIM, and how has it evolved over the years? Let's delve into the definition, history, and role of MIM in various industries.

Definition and History of MIM

MIM is a process that combines the high-volume capability of injection molding with the benefits of metallic materials. It involves mixing metal powders with a binder to form a feedstock, which is then injected into a mold to create a green part. The binder is subsequently removed, and the part is sintered to achieve its final properties.

The roots of MIM can be traced back to the 1970s, when the need for complex, high-volume metal parts began to grow. Over the years, advancements in material science and process control have significantly expanded the capabilities of MIM, making it a preferred choice for manufacturing precision metal parts.

The Role of MIM in Various Industries

MIM plays a crucial role in various industries, including automotive, aerospace, medical, electronics, and consumer goods. Its ability to produce complex parts with high precision and excellent mechanical properties makes it ideal for applications where performance and reliability are paramount. From surgical instruments and automotive components to aerospace parts and electronic devices, MIM has a wide range of applications.

Metal Injection Molding Process

The Metal Injection Molding (MIM) process is a multi-step procedure that transforms metal powders into solid, fully dense components. Each step in the process plays a crucial role in determining the quality and properties of the final product. Let's explore each of these steps in detail.

Feedstock Mixing

The MIM process begins with the preparation of the feedstock, a mixture of metal powders, and a binder. The metal powders provide the material properties of the final part, while the binder facilitates the molding process. The feedstock must be thoroughly mixed to ensure a uniform distribution of the metal powders in the binder.

Injection Molding

The mixed feedstock is then heated and injected into a mold under high pressure, similar to the process used in plastic injection molding. The mold is designed to produce a green part that has the shape of the final product but is larger to account for MIM shrinkage during sintering.

Debinding and Sintering

After the green part is removed from the mold, the binder is removed in a process called debinding. This leaves behind a porous part, known as a brown part, composed mainly of metal powders. The brown part is then heated to a high temperature in a controlled atmosphere in a process called sintering. Sintering causes the metal particles to bond together, resulting in a solid, fully dense part.

Shape Correction

Due to shrinkage during sintering, the final part may not have the exact dimensions of the mold. Therefore, shape correction processes, such as shape molding, machining, or grinding, may be necessary to achieve the desired dimensions and surface finish.

Advantages of Metal Injection Molding

MIM offers a host of advantages that make it a preferred choice for manufacturing complex, high-volume metal parts. Let's delve into these advantages and understand how MIM stands out.

The precision of MIM Parts

MIM is renowned for its ability to produce parts with high precision. The process can achieve tight tolerances, typically within ±0.3% of the nominal dimension, making it ideal for applications that require high dimensional accuracy. Especially for parts with relatively small dimensions, the MIM process can achieve higher precision.

The Complexity of MIM Parts

MIM excels at producing complex parts that would be difficult or impossible to manufacture using traditional methods. The process can handle intricate geometries, thin walls, and fine details, providing designers with a high degree of design freedom. This is because the shape complexity of metal injection molding comes from the plastic injection molding process. You can think that as long as it is a shape that plastic injection molding can produce, metal injection molding can produce it.

Cost-effectiveness Compared to Other Processes

When it comes to cost-effectiveness, MIM often outperforms other manufacturing processes, especially for the high-volume production of complex parts. To illustrate this, let's compare MIM with investment casting, another common method for producing metal parts.

MIM vs. Investment casting

Let's take the production of a 10mm stainless steel 17-4 PH cube as an example:

Comparison Aspect | Metal Injection Molding | Investment Casting |

Product 10x10x10mm SS316L cube | 7.85 Gram | 7.85 Gram |

Mold Cost | 2000 usd (High) | 1000 usd (Medium) |

Material Cost | 0.06 usd/pc (Medium) | 0.04 usd/pc (Low) |

Molding Cost | 0.2 usd/pc (Low) | 0.35 usd/ pc (High) |

Other Cost | 0.1 usd/pc | 0.05 usd/pc |

Tolerance | High (0.3%) +/-0.03mm | Medium (0.5%)+/-0.05mm |

Productivity | 4000 pcs per day | 1000 pcs per day |

Total cost | 0.36 usd/pc | 0.44 usd/pc |

It is not difficult to see that the price of the two processes is the same when producing 12,500 10mm cubes, but once more than 12,500 production units, if you use MIM production, you can get better quality and higher precision cubes at a lower price.

As the table shows, while the mold cost for MIM can be higher, the molding cost is significantly lower, making it more cost-effective for high-volume production. Furthermore, MIM offers better tolerance and productivity than investment casting.

Wide Range of MIM Materials Selection

MIM supports a wide range of materials, from steels and stainless steels to hard materials like tungsten carbide and special materials like titanium alloys. This allows manufacturers to choose the material that best meets the requirements of the application.

Hard Metal and High Melting Point Metal Forming

MIM is capable of forming hard and high melting point metals, which can be challenging to process using other methods. This opens up new possibilities for the production of high-performance parts.

Disadvantages of Metal Injection Molding

While MIM offers numerous advantages, it also has certain disadvantages that need to be considered. One of the main drawbacks is the higher initial cost, which can be a barrier for low-volume production or for companies with limited budgets. Let's break down metal injection molding costs to understand why the initial investment for MIM can be high.

Higher initial cost

MIM Mold Cost

The molds used in MIM are complex and require high precision, which makes them expensive to manufacture. However, these molds are durable and can be used to produce a large number of parts, which can offset the high initial cost over time.

MIM Material Cost

The cost of the metal powders used in MIM can be higher than the cost of bulk metals used in other processes. However, MIM offers the advantage of near-net-shape manufacturing, which can reduce material waste and lower the overall material cost.

MIM Debinding Cost

Debinding is a critical step in the MIM process and can add to the overall cost. The debinding process requires specialized equipment and can be time-consuming, especially for parts with complex geometries.

MIM Sintering Cost

Sintering is another critical step in the MIM process that can add to the cost. Sintering requires high temperatures and controlled atmospheres, which require energy and specialized equipment. However, sintering is a batch process, so the cost per part decreases with larger batch sizes.

MIM Shaping Cost

Shape correction processes, such as mold shaping, machining, or grinding, may be necessary to achieve the desired dimensions and surface finish. These processes can add to the cost, especially for parts with complex geometries or tight tolerances.

MIM Post Process Cost

Post-processing steps, such as heat treatment, polishing, or PVD, can also add to the cost. However, these steps can enhance the properties of the final part and may be necessary to meet the requirements of the application.

Despite these costs, MIM can still be cost-effective for the high-volume production of complex parts, as the high initial cost can be spread over a large number of parts.

MIM Parts Size Limitation

MIM is best suited for small to medium-sized parts. Usually, the size of MIM parts is most suitable for production within 2 inches (50mm). As the porous brown part collapses during sintering and forms the final product, there is a MIM shrinkage ratio that varies from material to material. If larger parts are produced, the amount of deformation during sintering will increase. Neway can produce MIM parts with a maximum size of 10 inches (250mm). The process becomes less efficient and more challenging for larger parts due to difficulties in achieving uniform density and handling the parts during the process. However, advancements in MIM technology are gradually overcoming these limitations.

Challenges in the MIM Process

The MIM process involves several complex steps, each of which must be carefully controlled to ensure the quality of the final product. For example, the feedstock must be thoroughly mixed, the molding parameters must be optimized, and the debinding and sintering processes must be carefully controlled. These challenges require a high level of expertise and quality control.

Considerations in Metal Injection Molding Production

Successful implementation of the MIM process requires careful consideration of various factors. These considerations play a crucial role in determining the quality, performance, and cost-effectiveness of the MIM parts. Let's explore these considerations in detail.

Importance of Binder Selection

The binder plays a critical role in the MIM process. It facilitates the molding process and is then removed during debinding. The binder must be selected to provide good flow properties during molding and to be easily removed during debinding without leaving any residue that could affect the properties of the final part.

Impact of Metal Powder Size

The size of the metal powders used in the feedstock can significantly impact the properties and performance of the MIM parts. Smaller powders can provide higher green strength and better surface finish but can also increase the viscosity of the feedstock, making molding more challenging. Therefore, the powder size must be carefully selected based on the requirements of the application.

Considerations for Mold Design

Mold design is another critical consideration in MIM. The mold must be designed to facilitate the flow of the feedstock, minimize the formation of defects, and allow for shrinkage during sintering. The design of the mold can also impact the cost and productivity of the MIM process.

Thin Wall of MIM Parts

MIM is capable of producing parts with thin walls, which can be advantageous for reducing weight and material usage. However, producing thin walls can be challenging due to difficulties in filling the mold and achieving uniform density. Therefore, the design of the part and the molding parameters must be carefully optimized.

Taking Neway as an example, if the part you design needs Neway to manufacture it with the MIM process, you need to consider that the thin wall of the MIM part should not be less than 0.35mm. If you must use a thinner wall such as 0.2mm, the thin wall must be capable of post-processing such as CNC machining

Conclusion

Metal Injection Molding (MIM) is a powerful manufacturing technology that offers a unique blend of high precision, complexity, and cost-effectiveness for the production of metal parts. By leveraging the versatility of injection molding and the strength of metals, MIM opens up new possibilities for designers and manufacturers.

However, like any technology, MIM has its challenges. The higher initial costs, size limitations of parts, and complexities of the process require careful consideration and expertise. Despite these challenges, the advantages of MIM often outweigh the disadvantages, especially for high-volume production of complex parts.

评论

发表评论